A kind of windproof net

A windproof net and mesh technology, applied in the field of windproof nets, can solve the problems of troublesome installation of steel wire ropes, cumbersome process, increase of working steps for pillars, etc., and achieve the effect of eliminating embedded parts, simple overall structure, and simplified installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

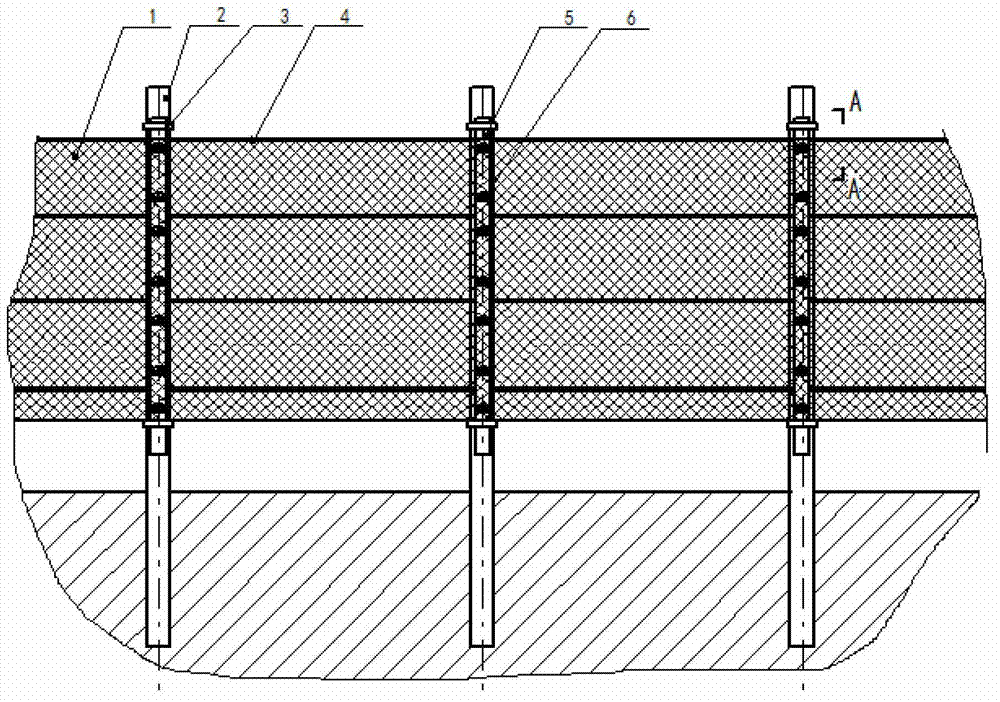

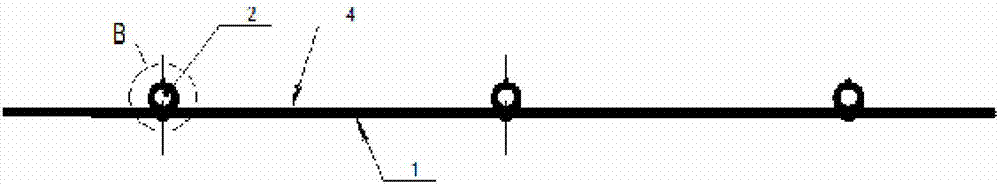

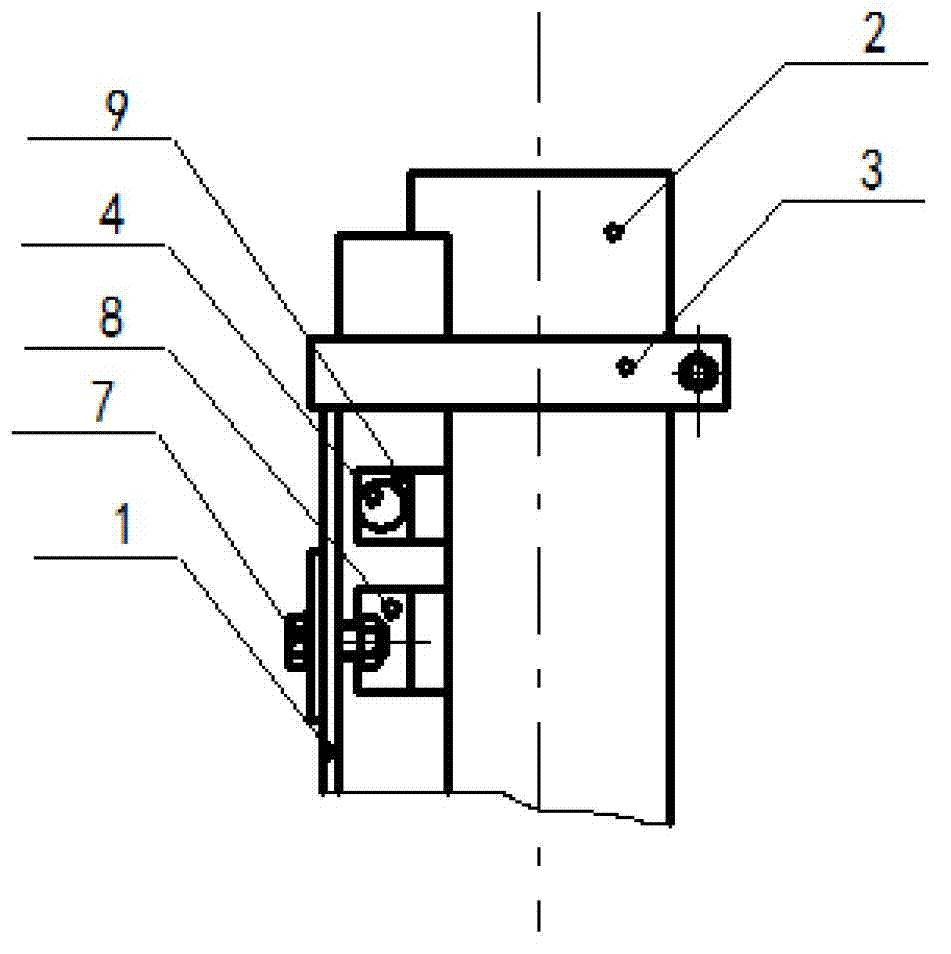

[0021] A windproof net along an electrified railway, comprising a column 2, a mesh 1, a steel wire rope 4, a channel steel 5 and fastening bolts 7, the channel steel is longitudinally fixed on the outer edge of the column, and the channel steel is uniformly distributed radially at intervals There is a square through hole 9, and the steel wire rope is worn in the square through hole; the mesh installation holes 8 are evenly distributed radially on one side of the channel steel, and the front thread of the channel steel corresponding to the mesh installation hole is threaded and installed. Fastening bolt, this fastening bolt is fixedly installed mesh by pressing plate 6 on the front of channel steel.

[0022] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com