Hydraulic system for 10m sand washer

A technology of hydraulic system and sand washing machine, which is applied in the direction of fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc. Service life, improve service life, prevent the effect of motor overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

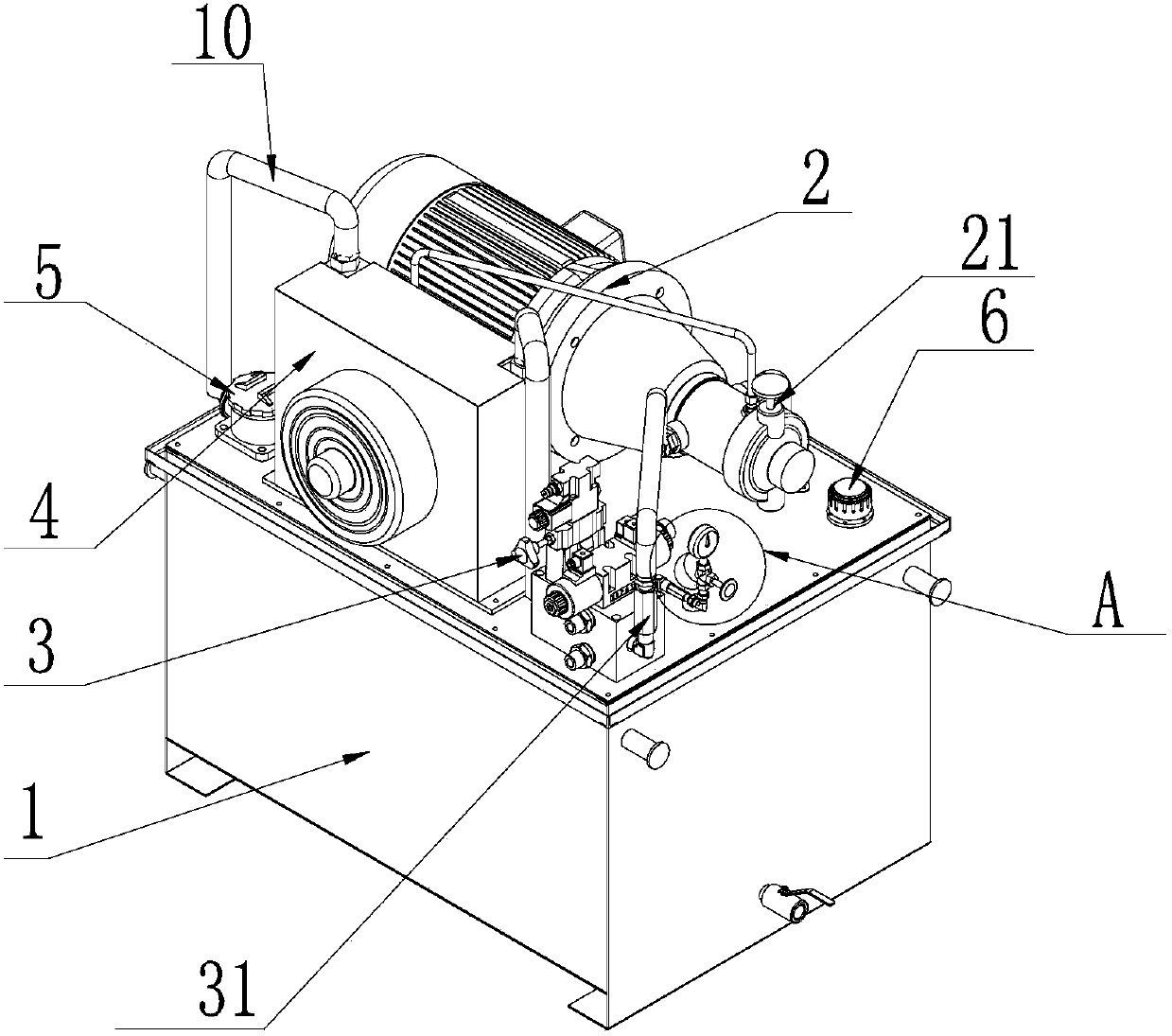

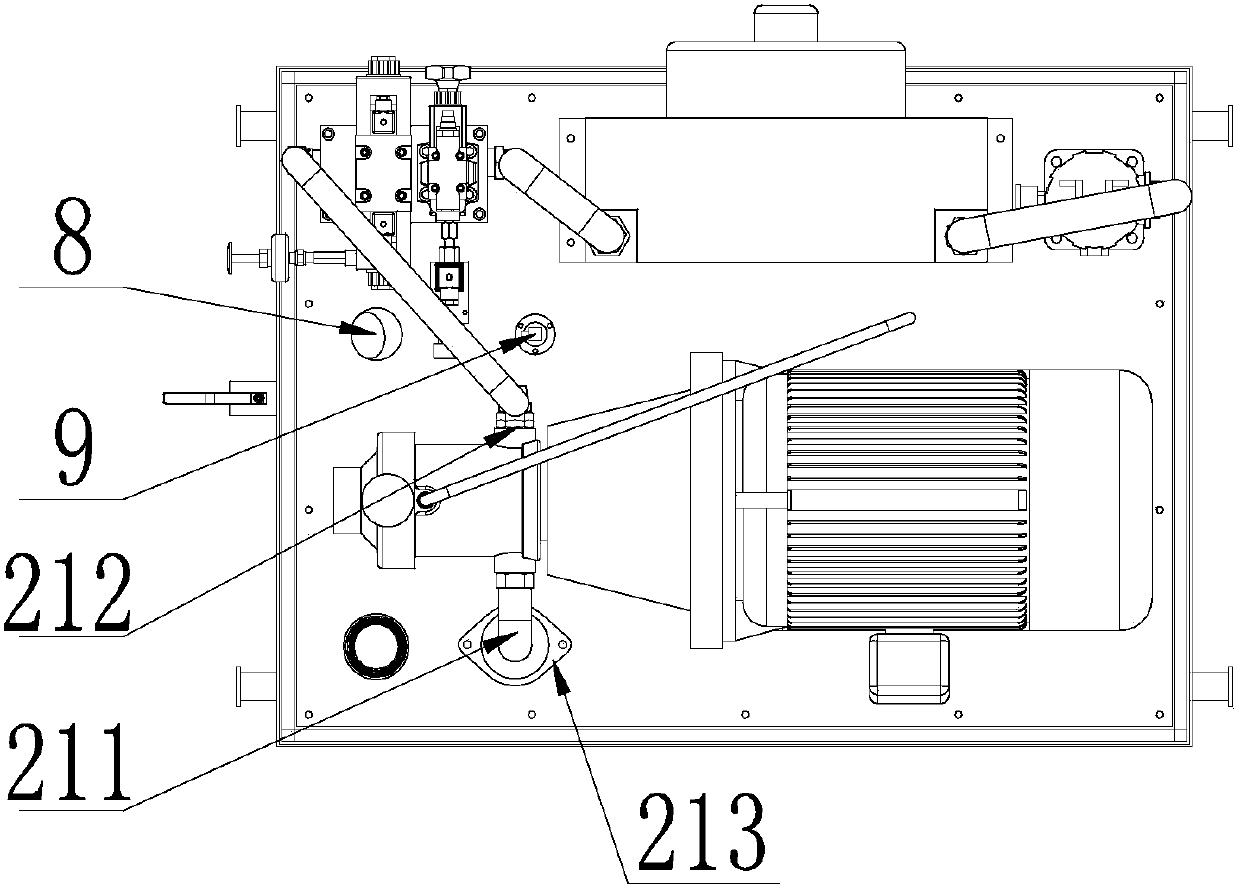

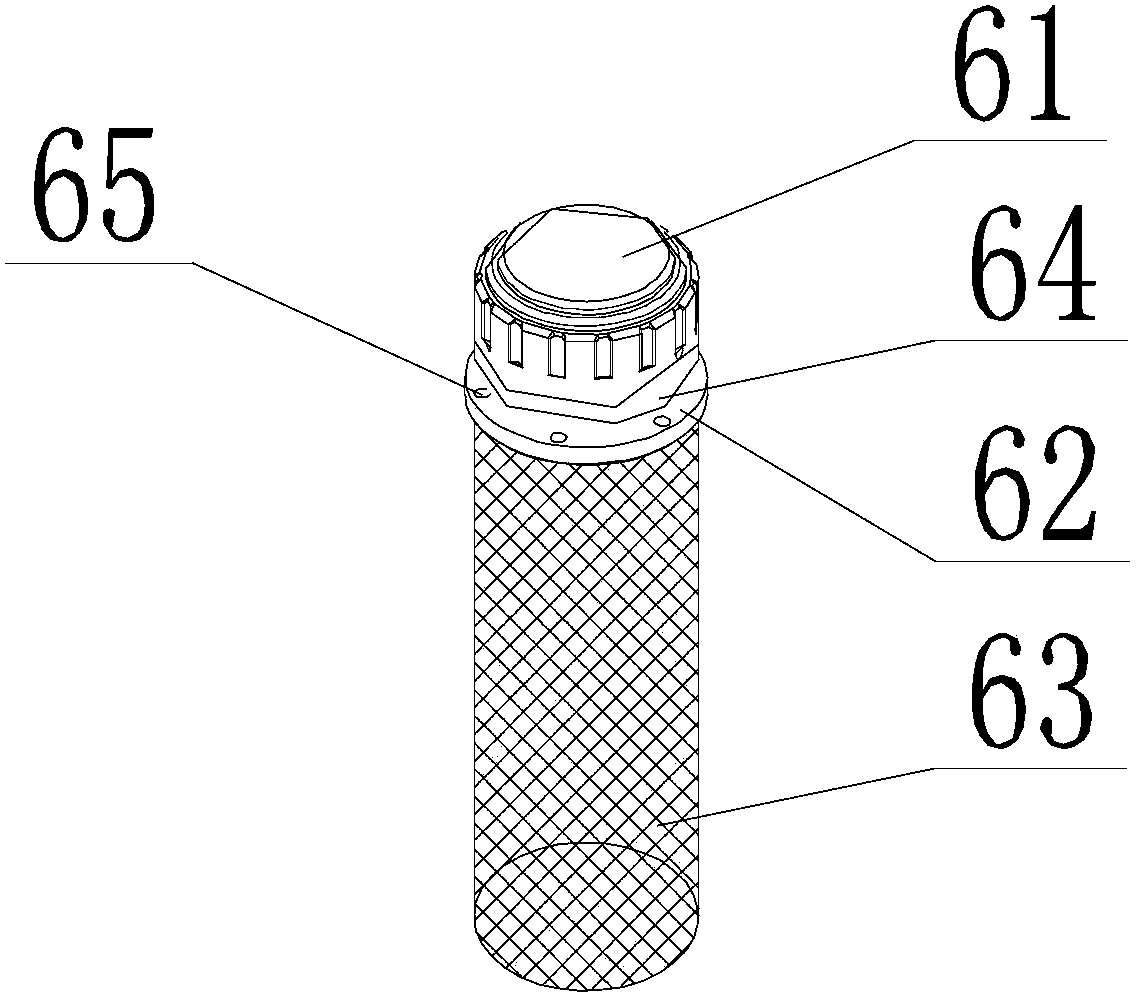

[0023] refer to figure 1 , figure 2 with Figure 4 , a hydraulic system for a ten-meter sand washing machine of the present invention, comprising a fuel tank 1, a motor 2, a valve group 3, an air cooler 4 and an oil return filter 5, and an air filter 6 and a pressure gauge are installed on the fuel tank 1 7. The temperature sensor 8 and the liquid level switch 9, the motor 2 is installed on the oil tank 1, the front end of the motor 2 is equipped with an oil pump 21, the power of the motor 2 is greater than or equal to 45KW, and the speed of the motor 2 is greater than or equal to 1450r / min, An oil suction filter 213 is installed on the oil pump 21, the rated flow rate of the oil pump 21 is greater than or equal to 105 L / min, and a check valve 31 is installed on one side of the valve group 3, and the oil pump 21 adopts a connecting pipe 10 and a one-way valve. The valve 31 is connected, one side of the air cooler 4 is connected with the valve group 3 through the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com