Condenser on-line cleaning robot dry-type boosting coil pipe system

A technology for cleaning robots and condensers, which is applied in the direction of cleaning heat transfer devices, lighting and heating equipment, etc. It can solve problems such as affecting the normal operation of the system and corrosion of high-pressure hose retracting devices, and achieve easy observation and balance pressure difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

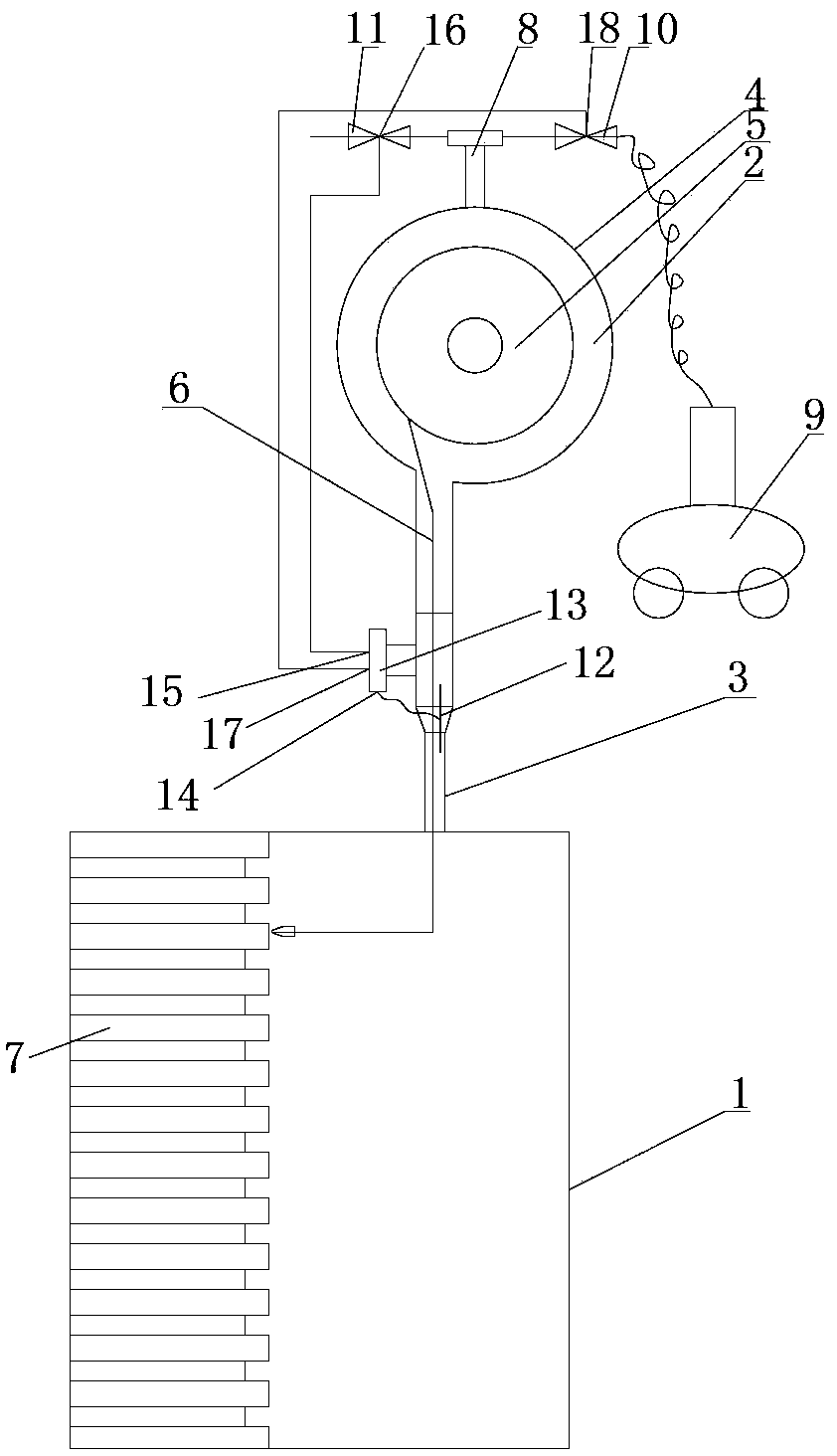

[0015] In the dry supercharged coil system of the condenser on-line cleaning robot of the present invention, the coil system is arranged above the condenser 1, and the coil system 2 is connected to the condenser 1 through the connecting pipe 3 below it. The coil system 2 includes a coil housing 4 and a high-pressure hose retracting device 5. The high-pressure hose retracting device 5 is arranged in the pre-coil housing 4, and the high-pressure hose retracting device 5 is wound with a high-pressure hose 6. Make the high-pressure hose 6 extend through the connecting pipe 3 into the position of the copper pipe 7 in the condenser 1 to realize the cleaning of the copper pipe 7 in the condenser. In order to prevent the problem of water flowing back into the coil housing 4 due to the pressure in the condenser 1 being greater than the pressure in the coil housing 4, the connecting pipe 3 is designed as a transparent pipe to facilitate real-time observation. An air inlet 8 is provided o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap