Test method for tightness of air duct air pressure and smoke detection

A test method and technology of detection method, which can be used in the use of liquid/vacuum for liquid tightness measurement, by detecting the appearance of fluid at the leak point, and by measuring the increase and deceleration rate of the fluid, etc., can solve problems such as rust marks on air ducts , to achieve accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

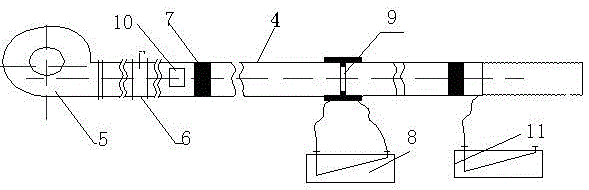

[0022] Such as figure 1 shown.

[0023] The air duct air pressure smoke detection tightness test method includes the smoke leak detection method, and the smoke leak detection method includes the following steps:

[0024] Step a, air duct sealing step: remove the branch pipe connected to the air duct, seal the opening of the removed branch pipe, seal the remaining ports of the air duct and maintain an air supply opening;

[0025] Step b, the installation step of the air supply device: take the centrifugal fan 5 and install it at the air supply opening of the air duct through the orifice plate 9;

[0026] Step c, detection tool installation step: install the air flow differential pressure gauge 8 at the orifice plate 9, and install a pipe static pressure differential pressure gauge 11 in at least one position in the air duct respectively;

[0027] Step d, smoke device installation step: Install the smoke generating device 10 at the orifice 9 or in the air duct or at the exit o...

Embodiment 2

[0043] Such as figure 1 As shown, the wind pressure smoke detection test system based on the air pressure smoke detection tightness test method of the air duct includes an air duct 4 that keeps the remaining ports sealed at one air supply opening, and a centrifugal fan 5 is arranged at the air supply opening through an orifice plate 9, An air intake differential pressure gauge 8 is installed at the orifice plate 9, and a static pressure differential gauge 11 is respectively installed in at least one position in the air duct; a smoke generator is installed at the orifice plate 9 or in the air duct or at the outlet of the centrifugal fan 5 device 10.

[0044] Between the centrifugal fan 5 and the through-hole plate 9 , from the centrifugal fan 5 to the through-hole plate 9 , a restrictor 6 and a rectifying grid 7 are arranged in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com