Waterborne automatically spraying paint for ironware and preparation method thereof

A technology of automatic spraying and small hardware, applied in the direction of epoxy resin coating, coating, etc., can solve problems such as skin allergies and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

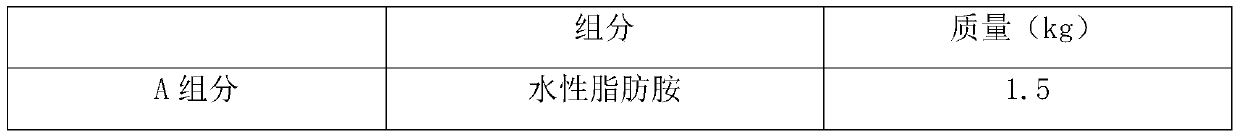

[0035] Each component and its quality of a kind of water-based hardware automatic spraying coating of table 1 embodiment 1

[0036]

[0037]

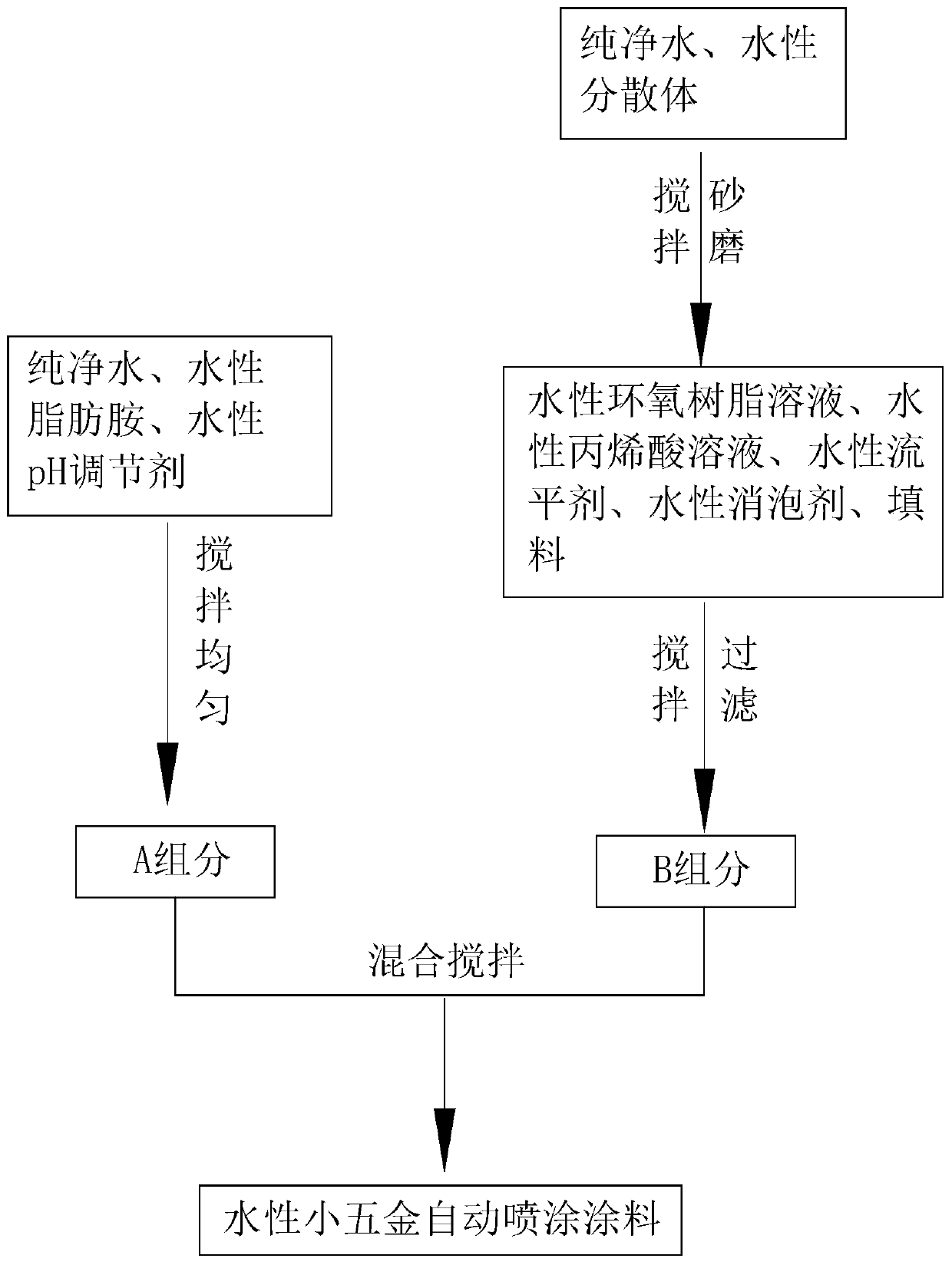

[0038] Such as figure 1 , the preparation method of the water-based hardware automatic spray coating, specifically comprises the following steps:

[0039] Step 1. Weigh the various substances in component A according to the formula amount, and add purified water, water-based fatty amine, CH 3 Si(OH) 2 SO 3 After the Na is stirred evenly, it is packaged to obtain component A of the water-based hardware automatic spray coating;

[0040] Step 2. Weigh the various substances in component B according to the formula, add pure water and water-based polyurethane in turn, stir at a speed of 500r / min, and stir for 30min. Sand mill until the particle diameter is 6-10um and stop to prepare a slurry material;

[0041] Step 3: After filtering the slurry prepared in step 2, add water-based epoxy resin solution, water-based acrylic acid solu...

Embodiment 2

[0045] Each component and its quality of a kind of water-based hardware automatic spray coating of table 2 embodiment 2

[0046]

[0047]

[0048] The preparation method of the water-based hardware automatic spraying coating specifically comprises the following steps:

[0049] Step 1. Weigh the various substances in component A according to the formula amount, add purified water, water-based fatty amine, and sodium bicarbonate in sequence, stir evenly, and pack to obtain component A of the water-based hardware automatic spray coating;

[0050] Step 2. Weigh the various substances in component B according to the formula, add pure water and water-based polyurethane in turn, stir at a speed of 700r / min, and stir for 10min. Sand mill until the particle diameter is 6-10um and stop to prepare a slurry material;

[0051] Step 3: After filtering the slurry prepared in step 2, add water-based epoxy resin solution, water-based acrylic acid solution, BYK-333, polyether-modified si...

Embodiment 3

[0055] Each component and its quality of a kind of water-based hardware automatic spray coating of table 3 embodiment 3

[0056]

[0057]

[0058] The preparation method of the water-based hardware automatic spraying coating specifically comprises the following steps:

[0059] Step 1. Weigh the various substances in component A according to the formula amount, and add purified water, water-based fatty amine, CH 3 Si(OH) 2 SO 3 After the Na is stirred evenly, it is packaged to obtain component A of the water-based hardware automatic spray coating;

[0060] Step 2. Weigh the various substances in component B according to the formula, add pure water and water-based polyurethane in turn, stir at a speed of 800r / min, and stir for 20min. Sand mill until the particle diameter is 6-10um and stop to prepare a slurry material;

[0061] Step 3, after filtering the slurry prepared in step 2, add water-based epoxy resin solution, water-based acrylic acid solution, BYK-333, polyet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com