Rumen bypass protein production method and equipment used by same

A production method and rumen-passing technology, applied in the field of plant-derived protein production, can solve the problems of inability to carry out large-scale continuous production, reduce protein digestibility, and high protein degradation rate, achieve obvious protection effect, uniform heat transfer, and achieve The effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

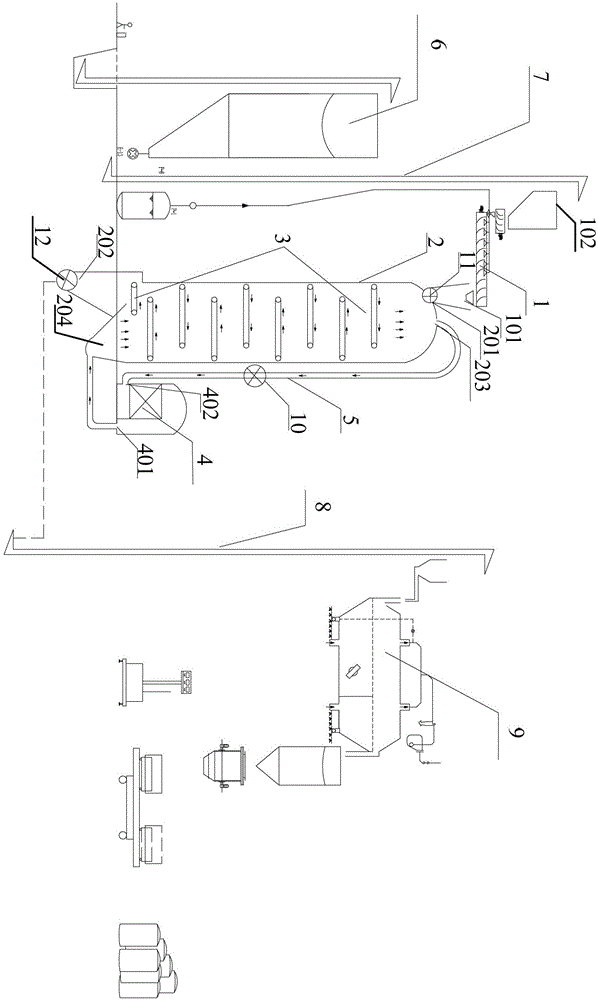

Image

Examples

Embodiment 1

[0044] Step (1): Prepare 20% glucose solution;

[0045] Step (2): Mix the crushed soybean meal and glucose solution evenly, and transport it to the metal conveyor belt in the reaction tower through the feeder, and the heat is quickly transferred to the soybean meal glucose-water mixture through the circulating hot air in the reaction tower, and the beauty is completed. Rad reaction; wherein the temperature of the hot air in the reaction tower is maintained at 80°C; the mixing ratio of the soybean meal and the glucose solution is 1:0.15 (mass ratio); the speed of the metal conveyor belt in the reaction tower is set to 5 minutes / meters, the total length of the metal conveyor belt is 120 meters.

[0046] Step (3): After completing the Maillard reaction, the soybean meal is dried and cooled to obtain the rumen-passed protein.

Embodiment 2

[0048] Step (1): Prepare 20% glucose solution;

[0049]Step (2): Mix the crushed soybean meal and glucose solution evenly, and transport them to the metal conveyor belt in the reaction tower through the feeder, and the metal conveyor belt is sequentially from the inlet of the reaction tower to the outlet of the reaction tower Arranged in parallel in the reaction tower from top to bottom, the circulating hot air in the reaction tower makes the heat quickly transfer to the soybean meal glucose-water mixture to complete the Maillard reaction; wherein the temperature of the hot air in the reaction tower is maintained at 100°C The mixing ratio of the soybean meal and the glucose solution is 1:0.2 (mass ratio); the speed of the metal conveyor belt in the reaction tower is set to 4 minutes / m, and the total length of the metal conveyor belt is 120 meters.

[0050] Step (3): After completing the Maillard reaction, the soybean meal is dried and cooled to obtain the rumen-passed protein....

Embodiment 3

[0052] Step (1): Prepare 20% glucose solution;

[0053] Step (2): Mix the crushed soybean meal and glucose solution evenly, and transport it to the metal conveyor belt in the reaction tower through the feeder, and the heat is quickly transferred to the soybean meal glucose-water mixture through the circulating hot air in the reaction tower, and the beauty is completed. Rad reaction; wherein the temperature of the hot air in the reaction tower is maintained at 120°C; the mixing ratio of the soybean meal and the glucose solution is 1:0.25 (mass ratio); the speed of the metal conveyor belt in the reaction tower is set to 2 minutes / meters, the total length of all metal conveyor belts is 120 meters.

[0054] Step (3): After completing the Maillard reaction, the soybean meal is dried and cooled to obtain the rumen-passed protein. The speed of the metal conveyor belt in the reaction tower is set to be 3 minutes / m, and the total length of the metal conveyor belt is 120 meters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com