Testing apparatus for mechanical grating ruling process

A technology of mechanical scribing and process testing, applied in diffraction grating, metal processing and other directions, can solve the problems of inability to set the installation angle, inability to adjust the levelness of the workpiece, and inability to monitor the three-way force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

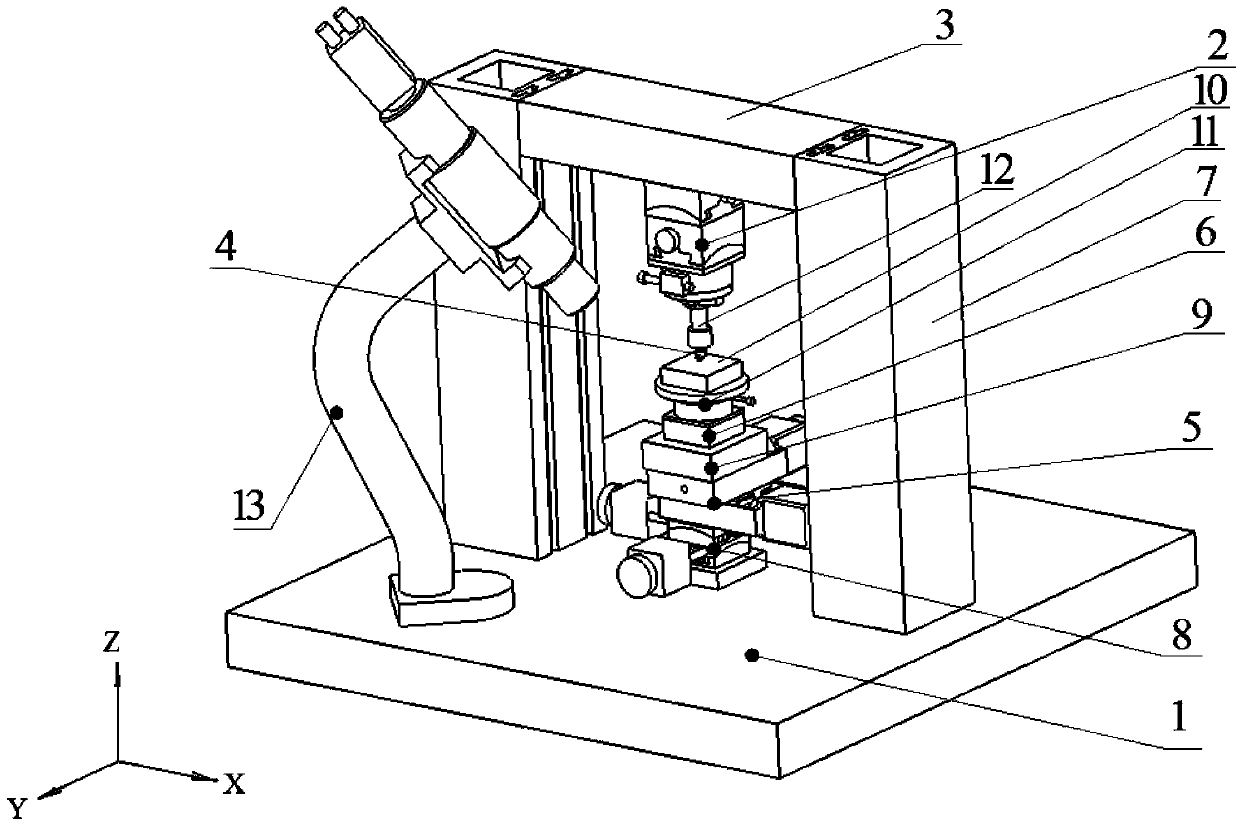

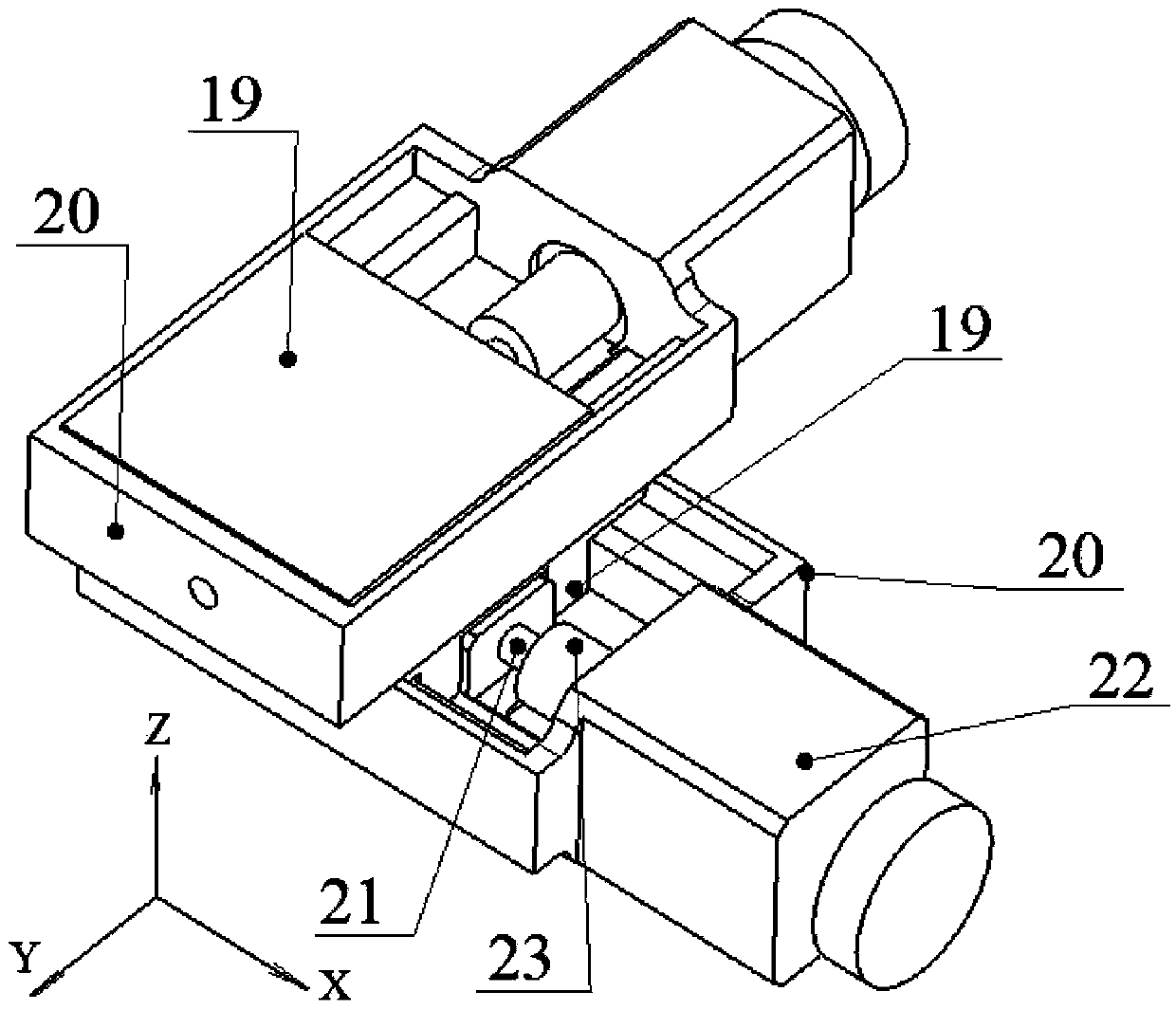

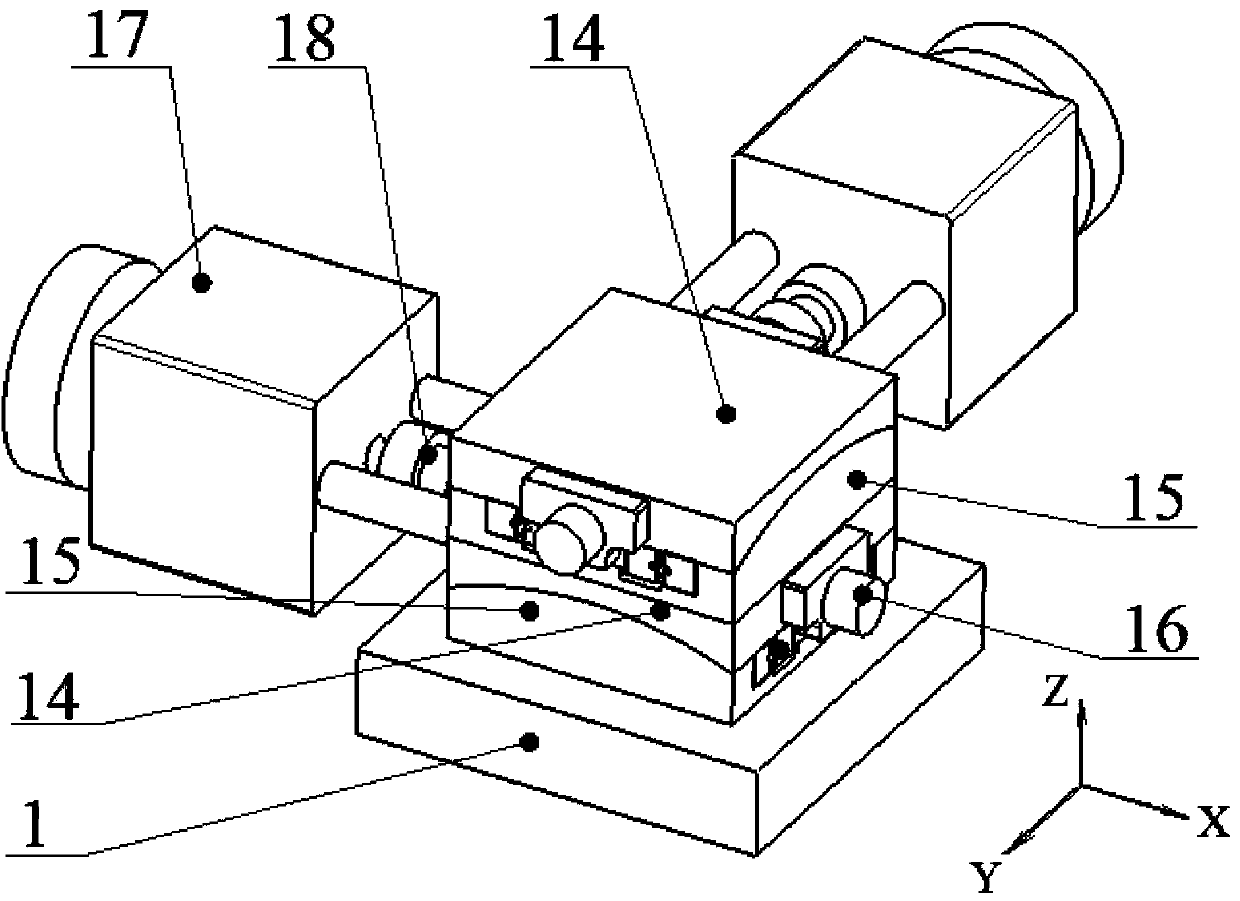

[0009] A grating mechanical scribing process test device, such as figure 1 As shown, the gantry suspension is installed on the base 1, and the knife rest 2 is rigidly suspended on the middle part of the gantry suspension crossbeam 3. Scoring cutter 4 is installed on knife rest 2 lower ends. The positioning platform corresponds to the tool rest 2 in the Z direction and is installed on the base 1 . The linear displacement platform 5 in the positioning platform is composed of the X-direction translation platform, the Y-direction translation platform, and the Z-direction translation platform 6. figure 1 , figure 2 shown. The two columns 7 of the gantry suspension are vertically fixed on the base 1, and the two ends of the beam 3 are connected with the inner sides of the two columns 7 through dovetail grooves. The arc displacement platform 8 in the positioning platform is formed by superimposing the X-axis arc displacement platform and the Y-axis arc displacement platform, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com