Wire cable labelling machine

A labeling machine and cable technology, which is applied in the field of cable labeling machines, can solve the problems of poor cable labeling quality, inflexible overall design, and inaccurate swing positioning, so as to improve labeling quality and efficiency, Compact structure and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

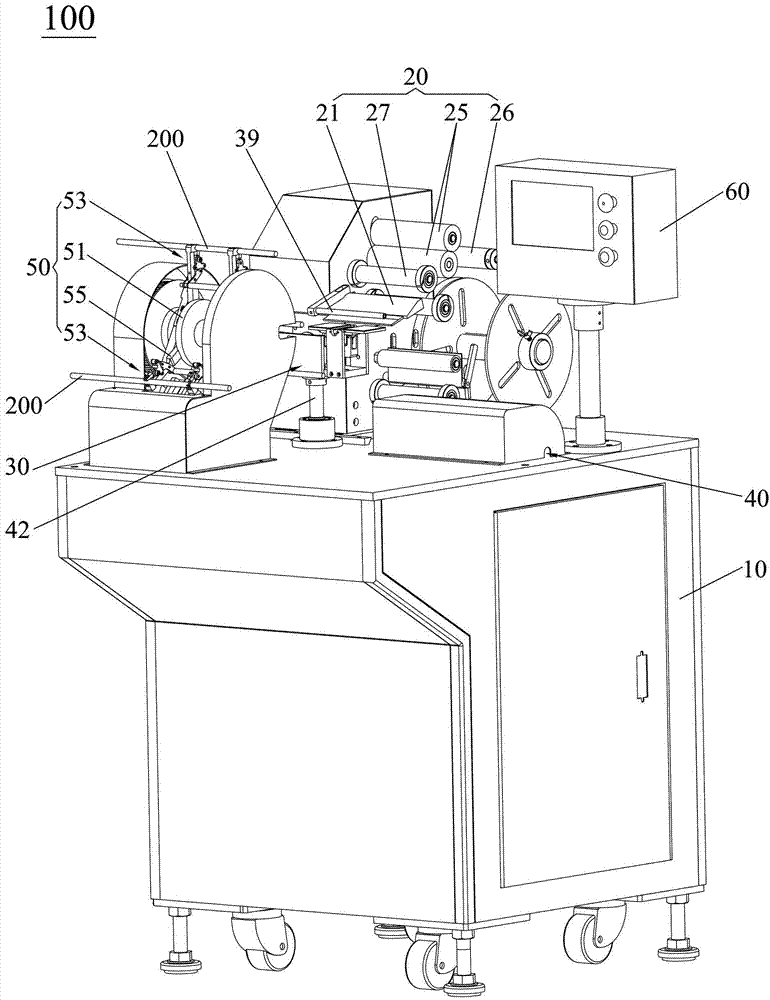

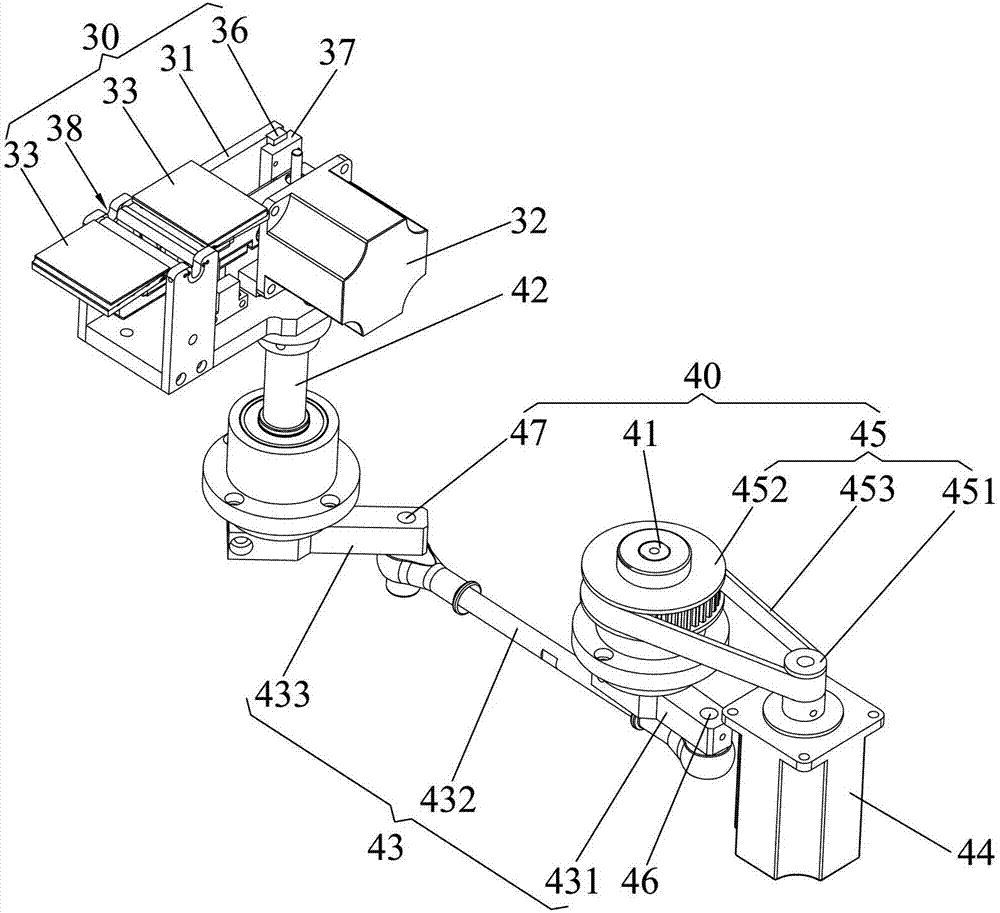

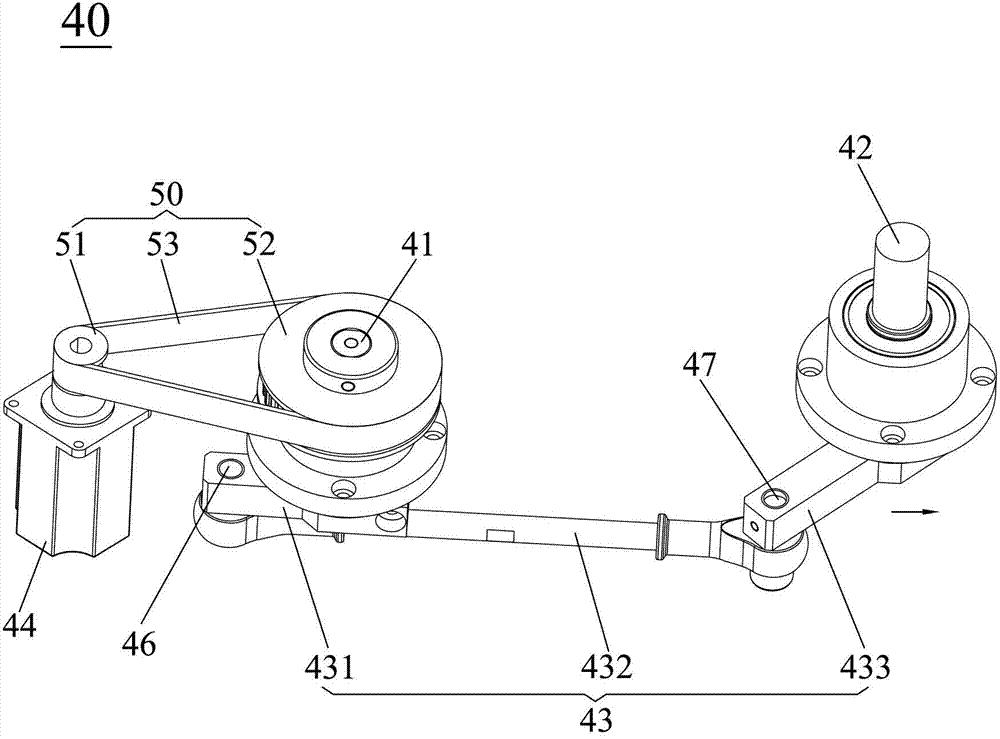

[0031] see Figure 1 to Figure 4 , the cable labeling machine 100 of the present invention is preferably electrically connected to a controller 60, so that the controller 60 can automatically control the cable labeling machine 100 of the present invention, wherein the cable labeling machine of the present invention The machine 100 includes a frame 10 , a self-adhesive conveying device 20 , a bonding device 30 , a cable conveying device 50 and a self-locking swing device 40 . Self-adhesive conveying device 20 is installed on the frame 10, and self-adhesive conveying device 20 comprises will as Figure 11 The strip-shaped self-adhesive 300 as shown is peeled off the self-adhesive label 310 (see Figure 8 ) and the peeling part 21 of the waste material 320, the peel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com