Mineral processing and deep purification method for quartz sand

A purification method, quartz sand technology, applied in the direction of silicon oxide, etc., can solve the problem of high iron content in quartz sand, achieve the effect of reducing dependence and improving utilization value

Inactive Publication Date: 2013-11-20

(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a deep purification method for quartz sand in order to solve the defect of high iron content in quartz sand existing in the existing deep purification method of quartz sand beneficiation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

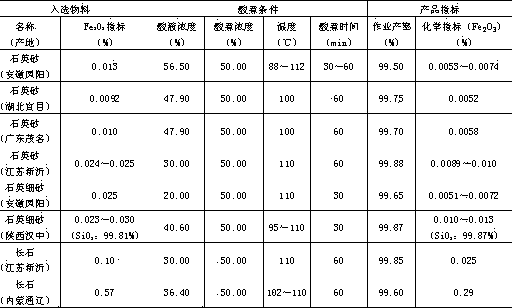

[0022] List of Examples

[0023]

[0024] Note: 1. Operating yield refers to the recovery rate of materials after acid cooking. Example: The operating yield is 99.5%, which means that 100kg of material is acid boiled to obtain 99.5kg and lose 0.5kg.

[0025] 2. Acid boiling concentration refers to the weight ratio of quartz sand and sulfuric acid solution.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mineral processing and deep purification method for quartz sand. The method comprises the following steps of (a) during the scrubbing of the quartz sand in an acid-digestion scrubbing machine, adding a sulfuric acid solution with the weight concentration of 15-60% for acid digestion, wherein the weight ratio of the quartz sand to the sulfuric acid solution is 25-65%, the temperature for acid digestion is 50-135 DEG C, the time for acid digestion is 20-90 minutes, and sulfuric acid can quickly react with iron-bearing minerals in the quartz sand through the organic combination of the mechanical scrubbing and acid digestion of the quartz sand; and (b) after acid digestion, separating the quartz sand from filtrate through filtrating, wherein the filtrate can be recycled, and products with Fe2O3 content meeting requirements are obtained after the quartz sand is cleaned. The method has the beneficial effects that aims which can not be achieved by the conventional mineral processing methods are realized, the dependence on high-quality siliceous resources is lowered, and the utility value of the quartz sand products is increased; and the method can also be applied to the field of the mineral processing and purification of non-metallic minerals, such as quartz fine (tail) sand, feldspar and the like.

Description

[0001] technical field [0002] The invention relates to a method for deep purification of quartz sand beneficiation, which utilizes H 2 SO 4 Rapid reaction with iron-containing impurity minerals ubiquitous in quartz to generate water-soluble Fe 2 (SO 4 ) 3 or FeSO 4 and was removed. Background technique [0003] Quartz (sand) is an important industrial mineral raw material, widely used in glass, ceramics, metallurgy, construction, electrical and electronics, aerospace and other fields, of which Fe 2 o 3 Content is a key factor affecting the quality of quartz sand products and their use value. With the development of science and technology and the progress of society, high-tech fields such as electrical and electronics, semiconductors, and aerospace have higher and higher requirements for quartz quality, and the demand for high-purity (low-iron) quartz sand is increasing, and high-quality quartz Mineral resources are increasingly depleted. Conventional beneficiation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B33/113

Inventor 彭寿吴建新段树桐茆令文谷翠红李佩悦

Owner (CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com