A method for preparing high-silicon non-oriented silicon steel

A technology of oriented silicon steel and high silicon, which is applied in the field of preparing high silicon non-oriented silicon steel, can solve the problems of destroying orderly arrangement, few reports, no process reports, etc., and achieves strong practicability, low cost, and simple and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

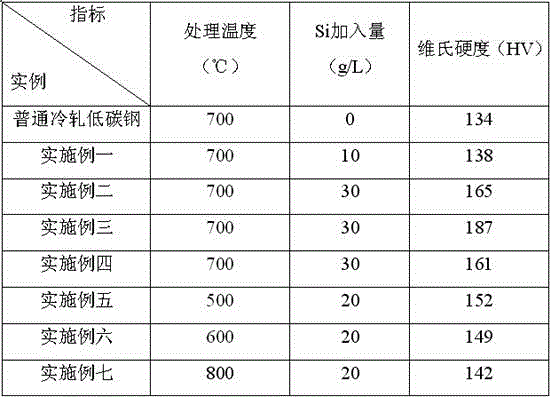

Examples

Embodiment 1

[0027] (1) The surface of ordinary cold-rolled low-carbon steel is polished, washed with water, ultrasonically cleaned, activated, and the surface is pre-plated with a layer of pure iron. The plating temperature is maintained at 40±1℃, and the cathode current density is 2A / dm. 2 , The plating time is 1800 seconds. Electroplating is performed under 45Khz ultrasonic conditions.

[0028] (2) A layer of Fe-Si alloy layer is deposited on the surface of the pre-plated steel sheet. Add 10g / L of nano-Si powder to the iron plating solution, and composite electrodeposition under the same temperature, current density and electroplating time under 45Khz ultrasonic conditions.

[0029] (3) Heat the electroplated steel plate in a hydrogen atmosphere furnace for 2 hours, control the heating rate at 10-20°C / min, raise the temperature to 700°C, hold time for 2 hours, and cool down with the furnace. The silicon content of the alloy layer obtained by the EDS and XPS testing of the sample after the a...

Embodiment 2

[0031] (1) The surface of ordinary cold-rolled low-carbon steel is polished, washed with water, ultrasonically cleaned, activated, and the surface is pre-plated with a layer of pure iron. The plating temperature is maintained at 40±1℃, and the cathode current density is 2A / dm. 2 , The plating time is 1800 seconds. Electroplating is performed under 45Khz ultrasonic conditions.

[0032] (2) A layer of Fe-Si alloy layer is deposited on the surface of the pre-plated steel sheet. Add 30g / L of nano-Si powder to the iron plating solution, and composite electrodeposition under the same temperature, current density and electroplating time under 45Khz ultrasonic conditions.

[0033] (3) Heat the electroplated steel plate in a hydrogen atmosphere furnace for 2 hours, control the heating rate at 10-20°C / min, raise the temperature to 700°C, hold time for 2 hours, and cool down with the furnace. The silicon content of the alloy layer obtained by the EDS and XPS detection of the sample after the...

Embodiment 3

[0035] (1) The surface of ordinary cold-rolled low-carbon steel is polished, washed with water, ultrasonically cleaned, activated, and the surface is pre-plated with a layer of pure iron. The plating temperature is maintained at 40±1℃, and the cathode current density is 2A / dm. 2 , The plating time is 3600 seconds. Electroplating is performed under 45Khz ultrasonic conditions.

[0036] (2) A layer of Fe-Si alloy layer is deposited on the surface of the pre-plated steel sheet. Add 30g / L of nano-Si powder to the iron plating solution, and composite electrodeposition under the same temperature, current density and electroplating time under 45Khz ultrasonic conditions.

[0037] (3) Heat the electroplated steel plate in a hydrogen atmosphere furnace for 2 hours, control the heating rate at 10-20°C / min, raise the temperature to 700°C, hold time for 2 hours, and cool down with the furnace. The silicon content of the alloy layer obtained by the EDS and XPS detection of the sample after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com