Roof waterproofing sealing strip

A waterproof sealing and waterproof edge technology, applied in the field of roof waterproof sealing strips and sealing waterproof materials, can solve problems such as difficulty in finding fault points, rain or leakage, waste of manpower, material and financial resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

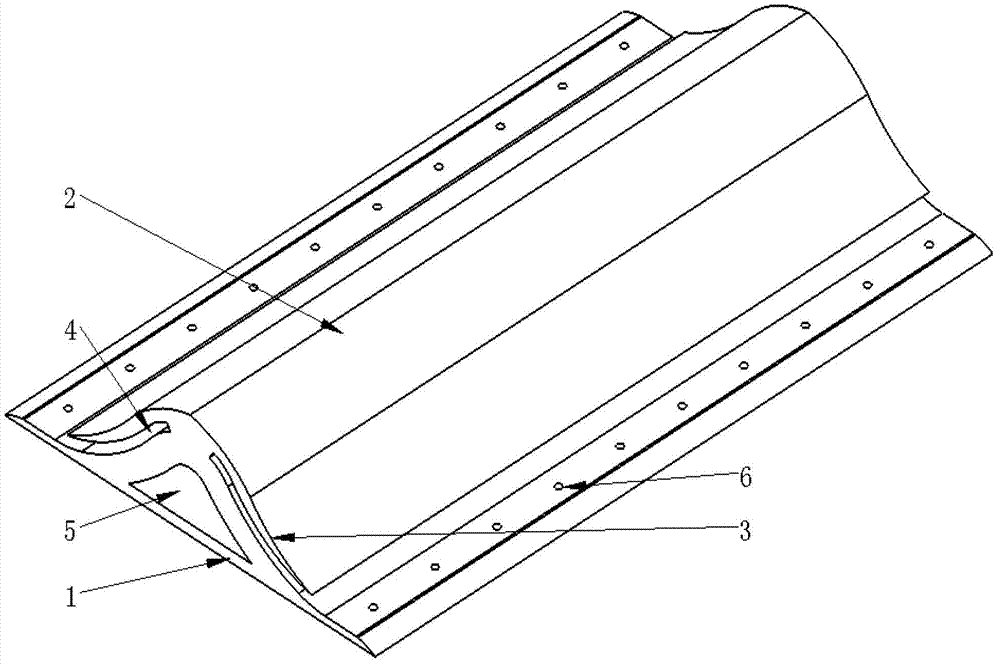

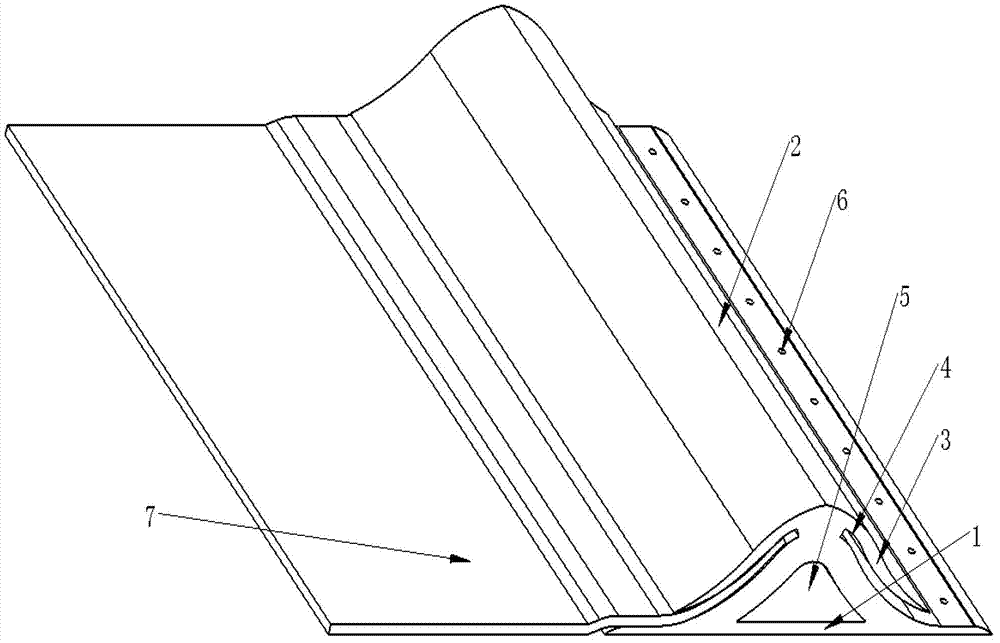

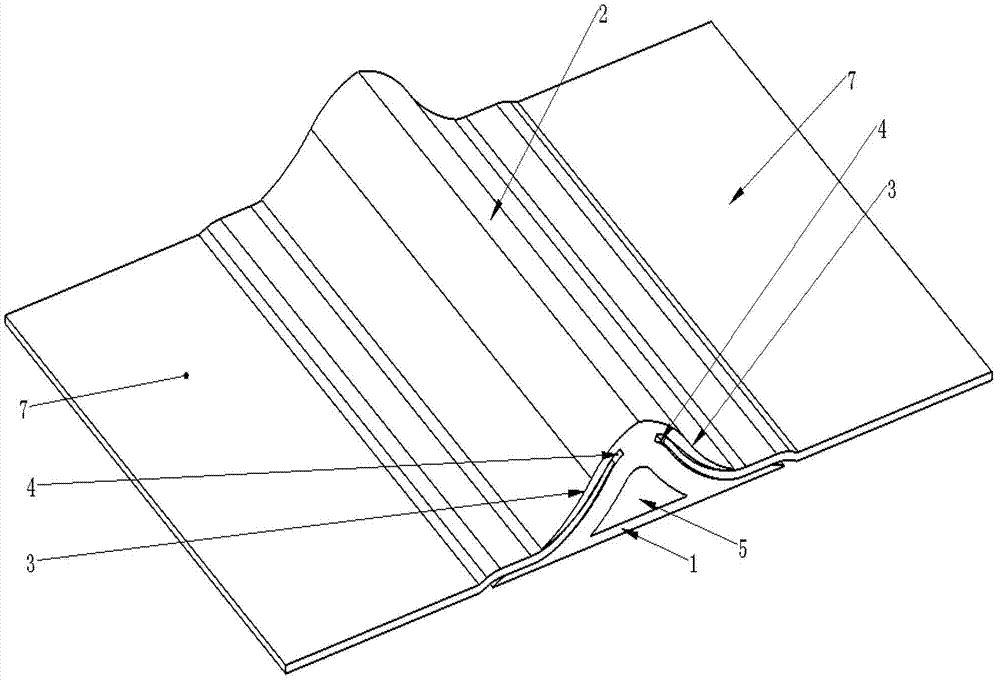

[0020] figure 1 Among them, the waterproof sealing strip of the present invention is made of elastic materials as a whole, which is convenient to relieve the force from the outside through the change of shape. The upper surface of the bottom plate 1 is an arc-shaped convex body 2, which can quickly divert accumulated water so that the water can flow down from the roof quickly. The bottom plate 1, the arc-shaped convex body 2, and the waterproof edge 3 are formed at one time. To further ensure the compactness of the material, the arc-shaped convex body 2 is provided with a combination channel 4 along the axial direction, and the combination channel 4 is symmetrically arranged on both sides of the center line of the bottom plate 1, forming a figure-eight shape, and the combination channel 4 is connected to the material to be combined. correspond. Combined with the through groove 4, it is mainly used to insert the linoleum) into the groove to perform the first sealing and the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com