A kind of automobile shock absorber bushing and shock absorber

A technology of automobile shock absorber and shock absorber, which is applied to springs/shock absorbers, springs made of plastic materials, mechanical equipment, etc., can solve problems affecting the strength of bushings, achieve firm combination and avoid relative rotation problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be described in detail below through specific examples. It should be understood that the following examples are only exemplary, and can only be used to explain and illustrate the technical solution of the present invention, and cannot be interpreted as the technical solution of the present invention. limit.

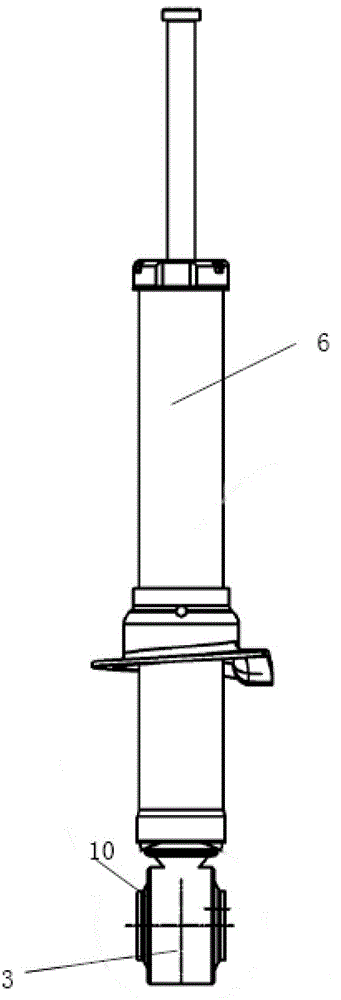

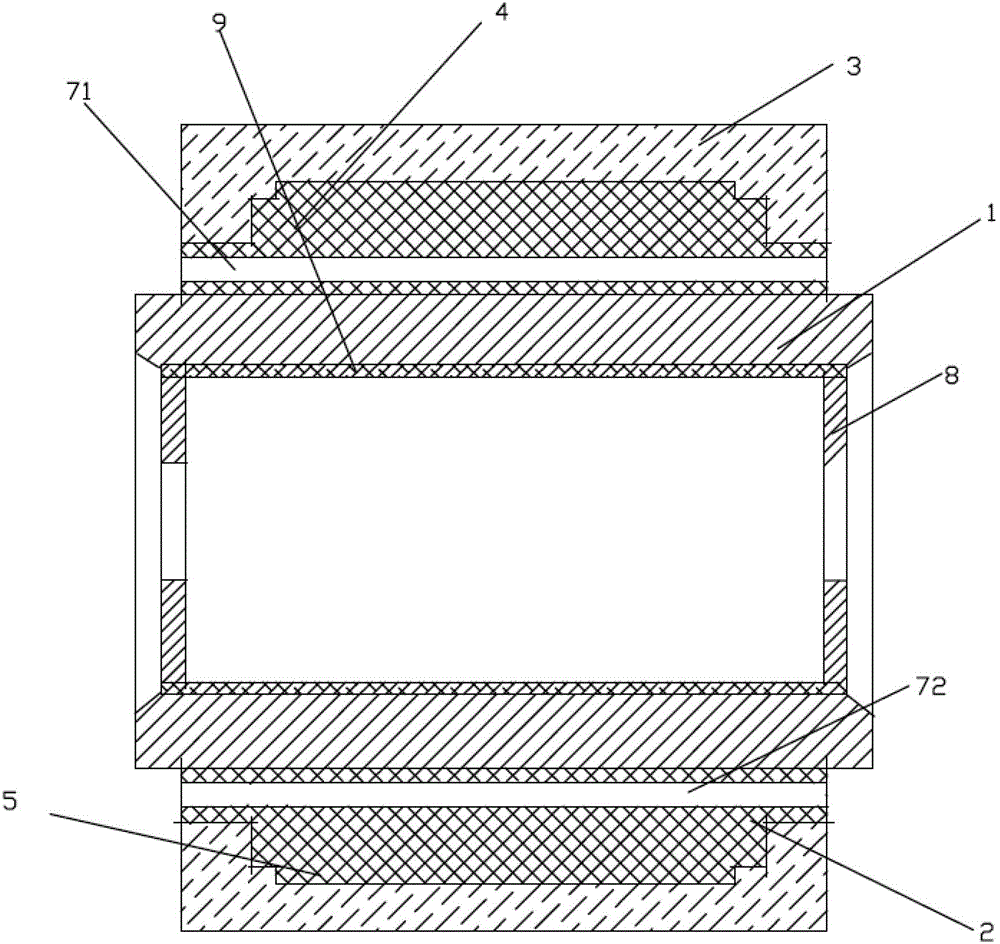

[0024] An automobile shock absorber bushing 10, comprising a sleeve body 3 connected to a shock absorber 6 body, an inner sleeve 1 and a rubber matrix 2; the rubber matrix 2 is fixed on the outer surface of the inner sleeve 1, and the outer surface of the inner sleeve 1 The surface is provided with independent protrusions or mesh structures. In this embodiment, the independent protrusions are cylindrical or polygonal pyramid structures perpendicular to the outer surface of the inner sleeve; the mesh structure is composed of a plurality of raised ribs intersecting each other. construction, the rubber matrix is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com