Rolling cylinder transmission device

A transmission device, cylinder technology, applied in the direction of fluid transmission device, transmission device, belt/chain/gear, etc., can solve the problems of load leakage and pressure loss, work difficulties, personal and equipment damage, etc., and achieves low processing accuracy requirements, The effect of reducing motion friction and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

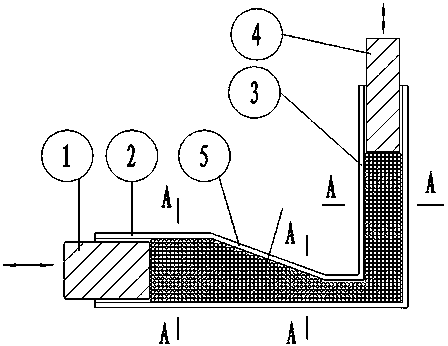

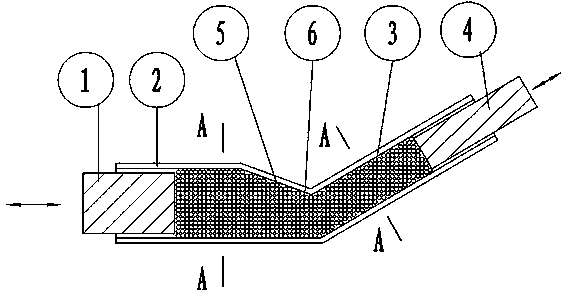

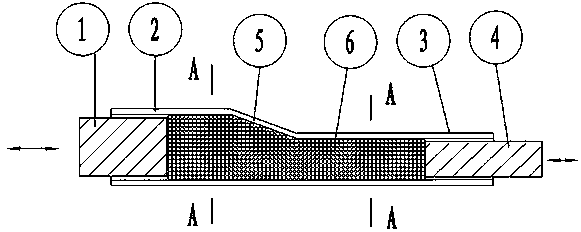

[0016] The roller transmission device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, the roller transmission device of the present invention is composed of an input cylinder 1, an input piston 2, a variable section transition section 3, an output cylinder 4, an output piston 5, and a roller 6. The input cylinder 1, the input piston 2, the variable section transition section 3, the output cylinder 4 and the output piston 5 are made of metal or non-metal, and its cross section can be rectangular, and its width is equal to the length of the roller body 6 and is a gap Cooperate. The roller body 6 is made of metal or non-metal, and its cross-sectional shape can be circular or elliptical. It can adopt a hollow structure, or it can use two materials that are light inside and hard outside to make an inner and outer double-layer structure (such as Figure 5 shown), in addition, the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com