Improved structure of flying-probe fixing seat for flying-probe tester

A flying probe testing machine and improved structure technology, which is applied in the field of flying probe testing machines, can solve problems such as cost waste, and achieve the effects of saving maintenance time, fast and convenient replacement, and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

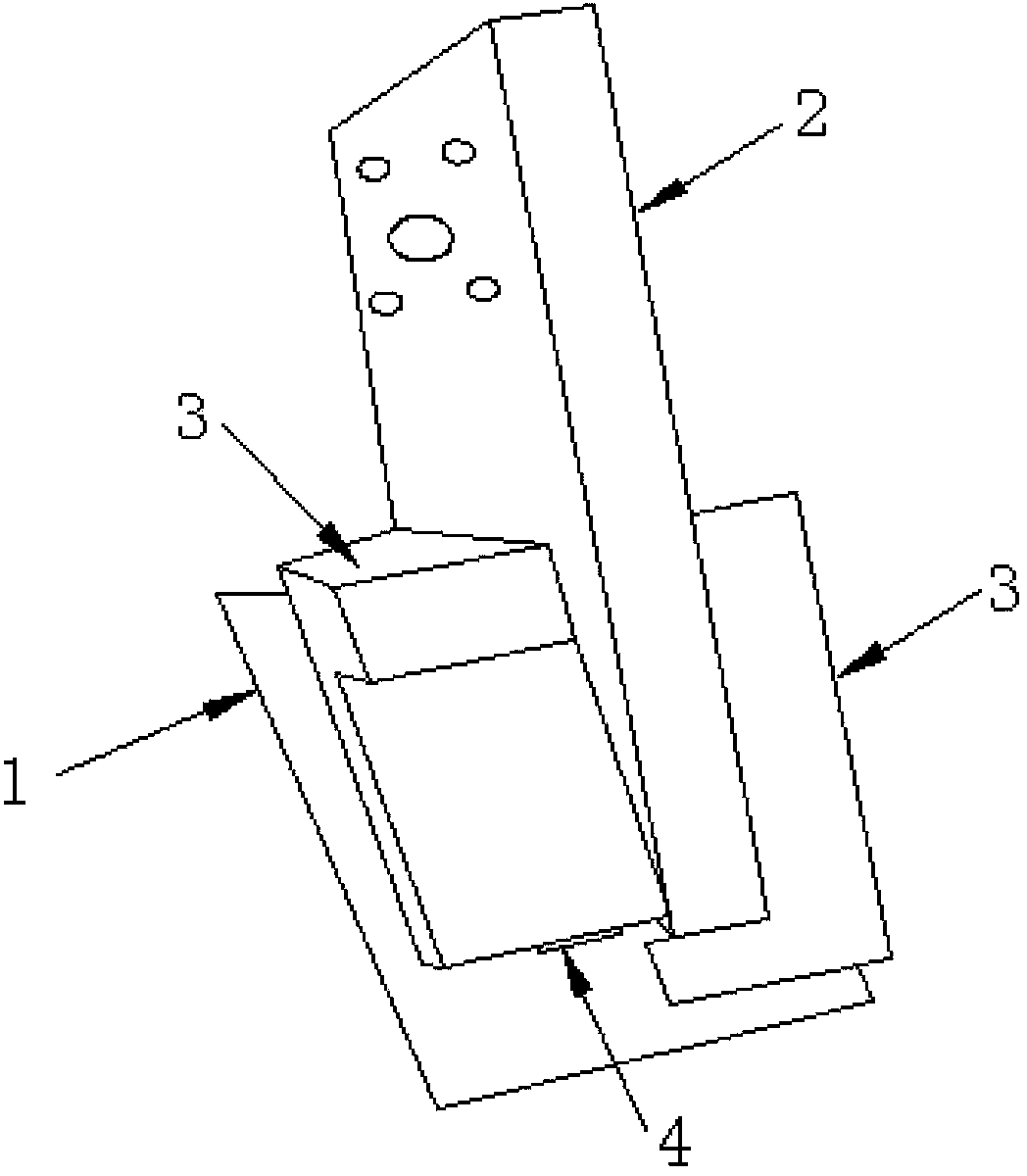

[0019] An embodiment of an improved structure of a fixed flying probe seat for a flying probe testing machine of the present invention will be described in detail below with reference to the accompanying drawings.

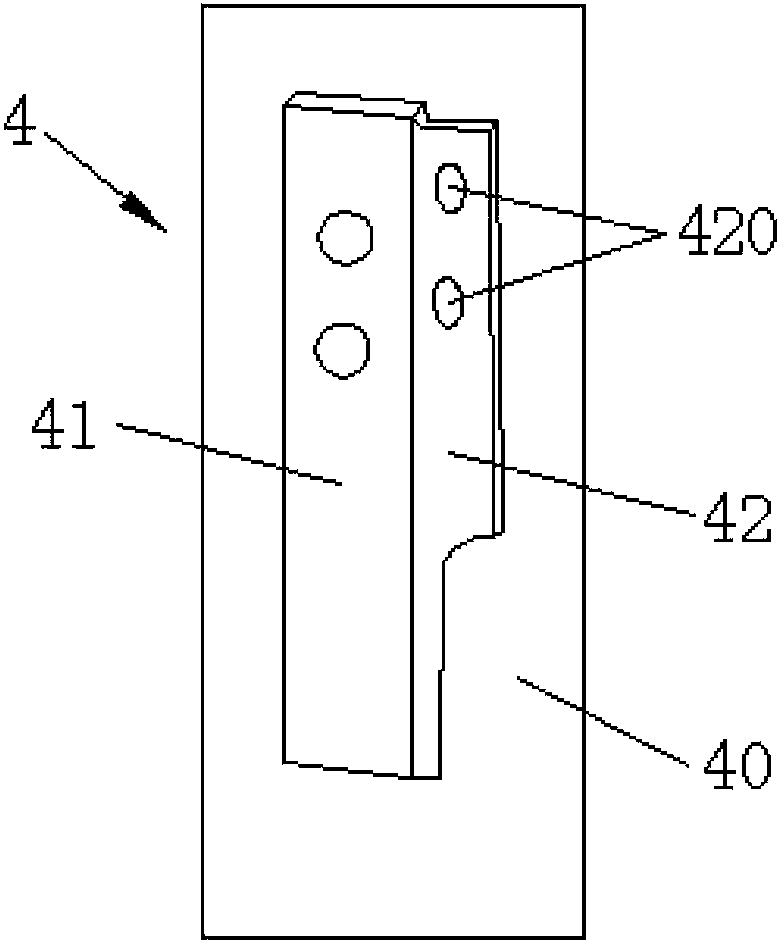

[0020] An improved structure of a fixed flying probe seat for a flying probe testing machine according to the present invention, the fixed flying probe seat includes a base 1 and a circuit board 2 for electrically connecting to test probes, one side of the base 1 It is used to locate the driving device connected to the flying probe testing machine, the other side of the base 1 is positioned with the circuit board 2, the circuit board 2 has a front and a back, and the circuit board 2 respectively Insulators 3 are positioned on the front and back of the body; a fixing member 4 for positioning and installing the test probe is also provided, and the fixing member 4 is detachably connected to one of the insulating members. The original one-piece structure is improved to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap