Piecewise sliding contact line power supply connection method and connection device thereof

A technology of power connection and sliding contact line, which is applied in the connection/disconnection, connection, circuit and other directions of the connection device, and can solve the problems of not meeting the use requirements, alignment accuracy problems, affecting production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

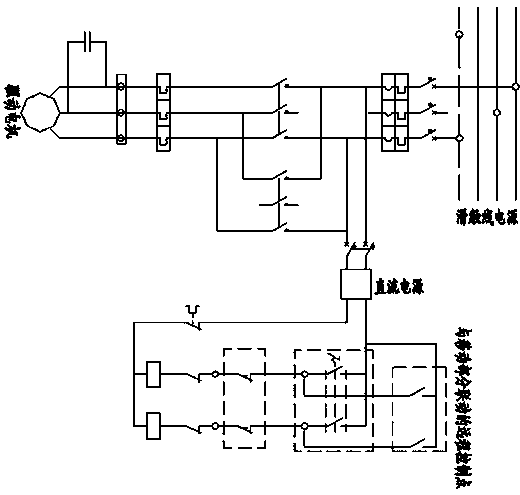

[0021] Embodiment 1, the present invention provides a power connection method for segmented trolley lines, by setting a section at the fracture between a horizontally installed fixed trolley line and a moving trolley line or between a fixed trolley line and an inspection section trolley line Driven by the deceleration transmission mechanism, the copper bar that can move up and down in the vertical direction; the power supply is realized by connecting the fixed trolley line and the moving trolley line or the fixed trolley line and the inspection section trolley line by putting down the copper bar; The row disconnects the connection between the fixed trolley line and the moving trolley line or the fixed trolley line and the maintenance section trolley line to realize power off, and safely and reliably realizes the connection or disconnection of the electrical connection between the two segment trolley lines .

[0022] In the present invention, the reduction transmission mechanis...

Embodiment 2

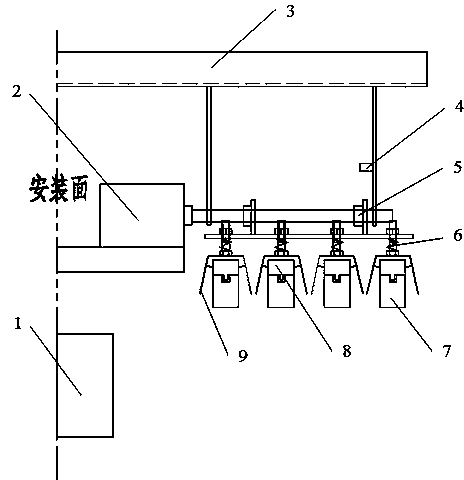

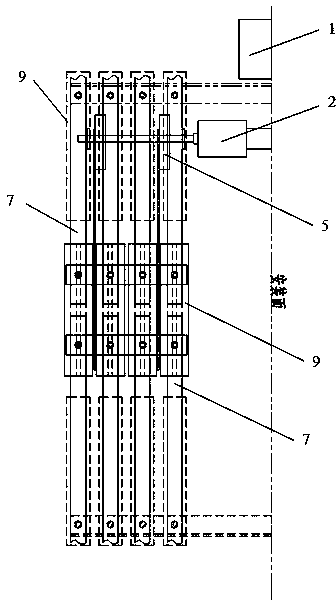

[0024] Embodiment 2, as shown in the accompanying drawings, the present invention also provides a segmented trolley line power connection device that is simple in structure, easy to operate, safe and reliable, and low in cost, and can realize the above-mentioned segmented trolley line power connection method. The section trolley line power connection device is set at the fracture between the fixed trolley line and the moving trolley line or between the fixed trolley line and the inspection section trolley line, including the copper bar 8, the mounting bracket 3, the reduction transmission mechanism 5, the motor 2 and the control box 1; the cross section of the copper bar 8 is "convex" type, and the width of the protruding part is 10mm narrower than the width of the groove on the upper part of the conductor of the trolley line 7; the installation bracket 3 is installed and fixed on the installation surface, and the installation bracket 3 Provide a base for the motor 2 and a fulc...

Embodiment 3

[0025] The third embodiment differs from the second embodiment in that the reduction transmission mechanism 5 is a cam mechanism or a link mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com