Optical fiber fixing device coupled with high-power semiconductor laser

An optical fiber fixing device and semiconductor technology, which is applied to semiconductor lasers, lasers, laser parts, etc., can solve problems such as poor heat dissipation, increased temperature of metal sleeves and optical fiber dispensing positions, and burnt optical fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

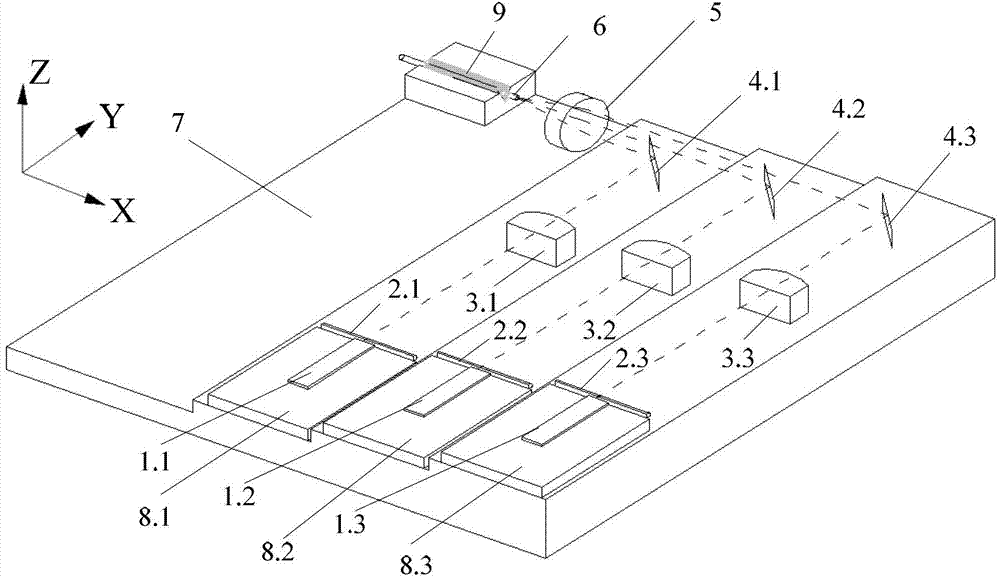

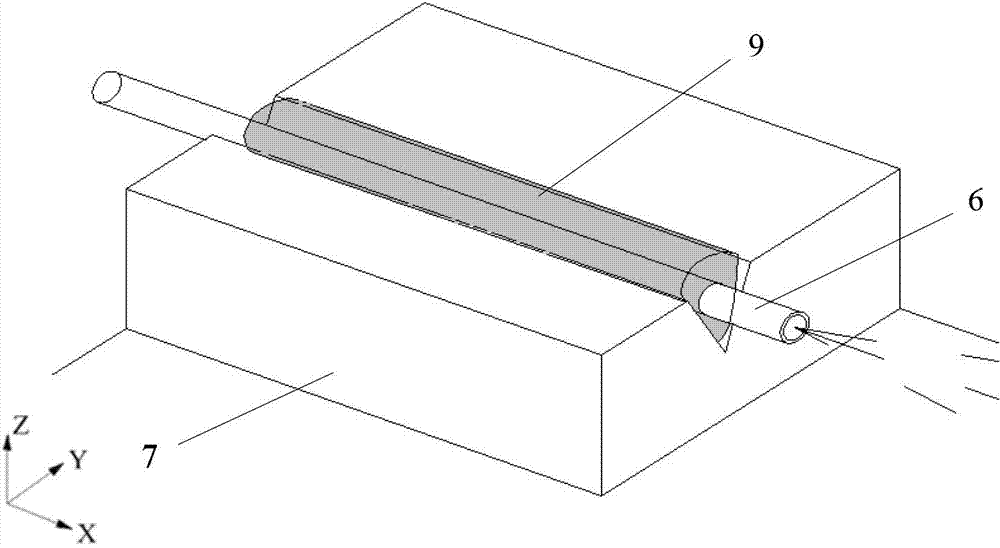

[0018] Such as figure 1 As shown, a high-power semiconductor laser coupled optical fiber fixing device, the high-power semiconductor laser includes three tube laser diodes (1.1-1.3), three fast-axis collimator mirrors FAC (2.1-2.3), three slow-axis collimators Straight mirror SAC (3.1-3.3), three mirrors (4.1-4.3), collimating lens 5, optical fiber 6, base 7, substrate (8.1-8.3), glass solder 9; three substrates (8.1-8.3 ), three fast-axis collimating mirrors FAC (2.1-2.3), three slow-axis collimating mirrors SAC (3.1-3.3), and three mirrors (4.1-4.3) are respectively fixed on different steps of the base 7, each Three laser diodes are fixed on a substrate, and the three laser diodes generate three beams with different heights, which produce parallel beams with different heights after passing through their respective fast-axis collimating mirrors FAC and slow-axis colli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap