Steel pipe tower flange screw replacement work platform

A technology of working platforms and steel pipe poles, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of increasing the labor intensity of operators and operating risks, the flange connection cannot be safe and reliable, and the operation is inconvenient, etc., to achieve light weight , Simple structure, convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

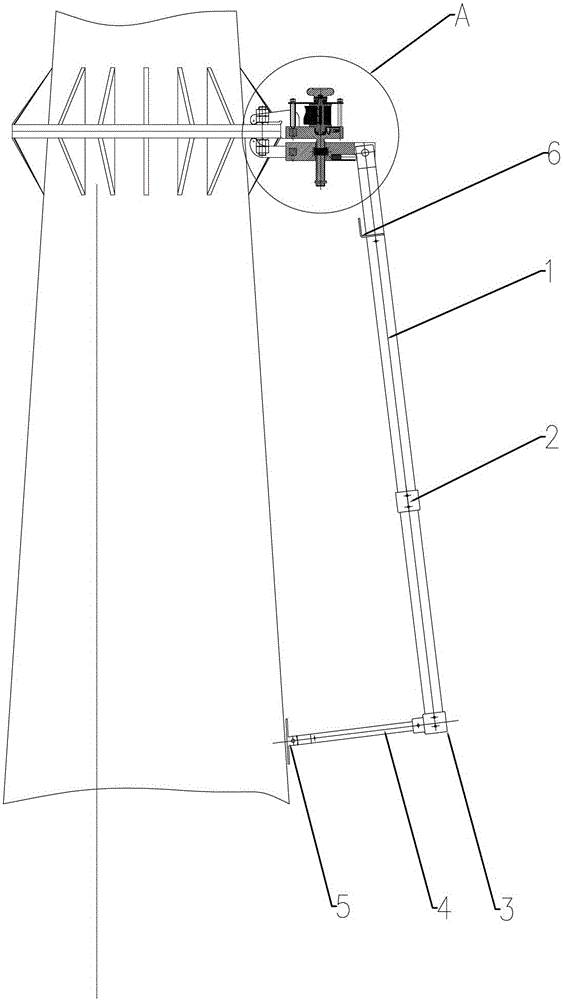

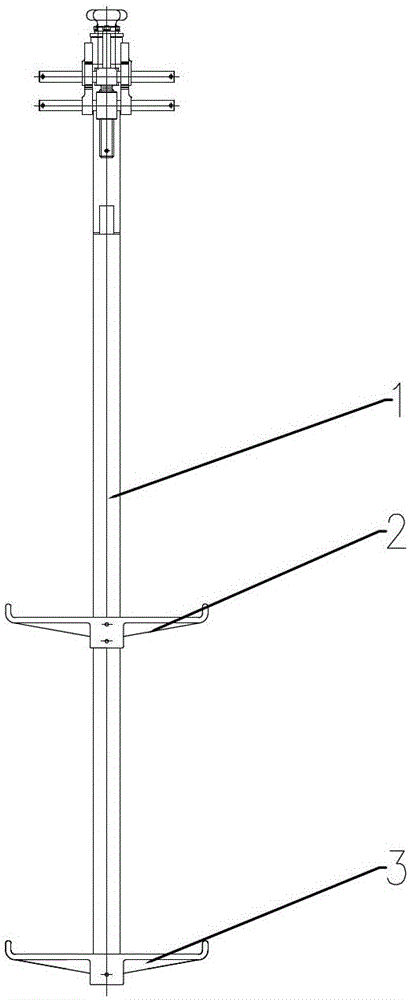

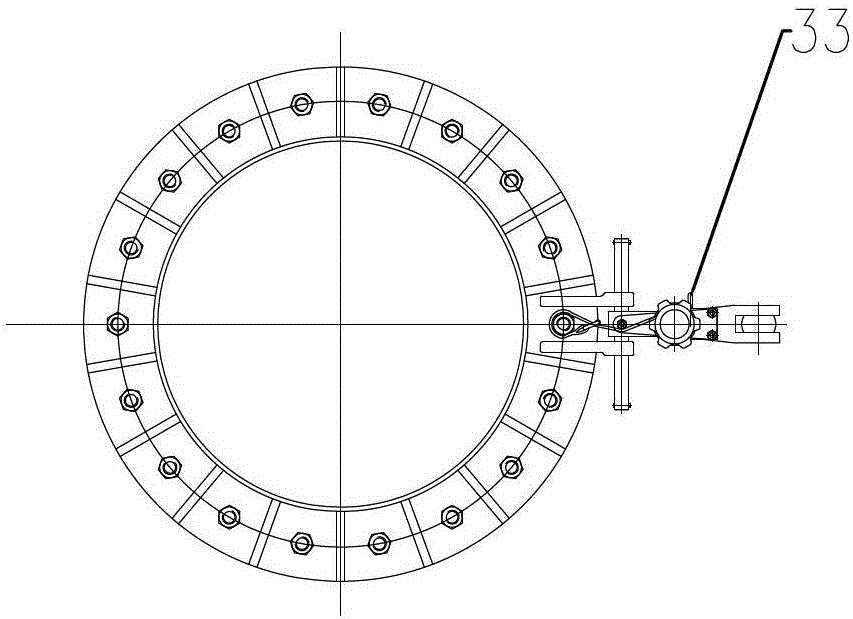

[0021] Such as Figure 1~4 As shown, the present invention mainly comprises upper support seat 7, lower support seat 8 and ratchet 30, and lower support seat 8 is provided with adjusting nut 11, and upper support seat 7 lower end is provided with adjusting screw rod 12, and adjusting screw rod 12 runs through lower support seat 8 And be screwed with adjusting nut 11. The end of the adjusting screw 12 is provided with a limit pin 13, and the limit pin 13 prevents the adjusting screw 12 from disengaging from the lower bracket seat 8. The relative distance between the upper bracket base 7 and the lower bracket base 8 is adjusted by adjusting the screw rod 12 and the adjustment nut 11 .

[0022] The front part of the upper end of the upper bracket seat 7 is connected to the first double-ended screw rod 21, the rear part of the upper end of the upper brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com