Method for determining SEBS content in polypropylene blending material

A determination method and polypropylene technology, which are applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of inaccurate detection of SEBS content and large thickness measurement errors, so as to facilitate the determination process and improve the accuracy. , the effect of improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] PP and SEBS were blended and granulated at a ratio of 98:2 to obtain a control sample with a SEBS content of 2%.

[0039] PP and SEBS were blended and granulated at a ratio of 95:5 to obtain a control sample with a SEBS content of 5%.

[0040] PP and SEBS were blended and granulated at a ratio of 90:10 to obtain a control sample with a SEBS content of 10%.

[0041] PP and SEBS were blended and granulated at a ratio of 85:15 to obtain a control sample with a SEBS content of 15%.

[0042] PP and SEBS were blended and granulated at a ratio of 80:20 to obtain a control sample with a SEBS content of 20%.

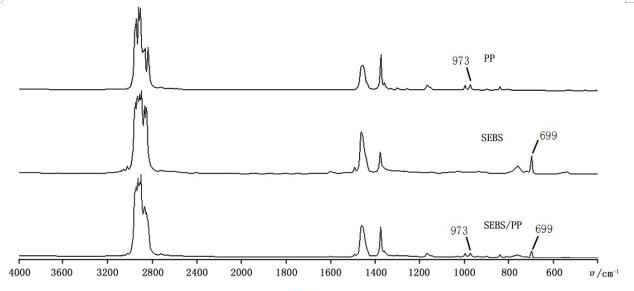

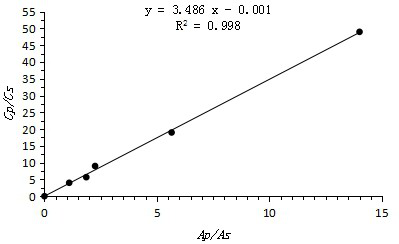

[0043] Take control samples with SEBS content of 2%, 5%, 10%, 15%, and 20% to scan the infrared spectrum, and record the absorbance AP at a wavenumber of about 973-1 (polypropylene characteristic) in each control sample, and the wavenumber Absorbance AS of about 699-1 (characteristic of the benzene ring). by formula The K value was calculated and verified, and the lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com