Defoaming method and defoaming device

A defoaming device and defoaming technology, applied in separation methods, chemical instruments and methods, packaging, etc., can solve problems such as inability to improve defoaming performance, decrease in laser light concentration, and decrease in defoaming efficiency, and achieve energy attenuation Reduction, improvement of energy utilization efficiency, and pollution prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

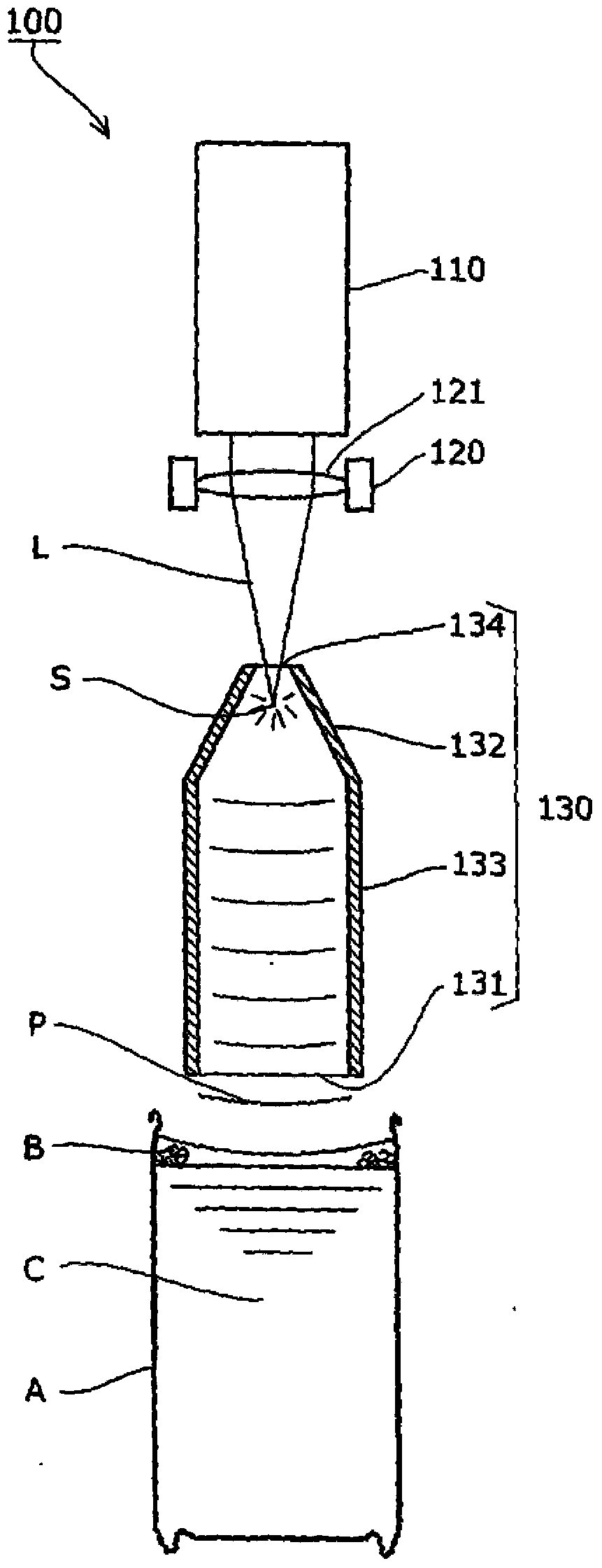

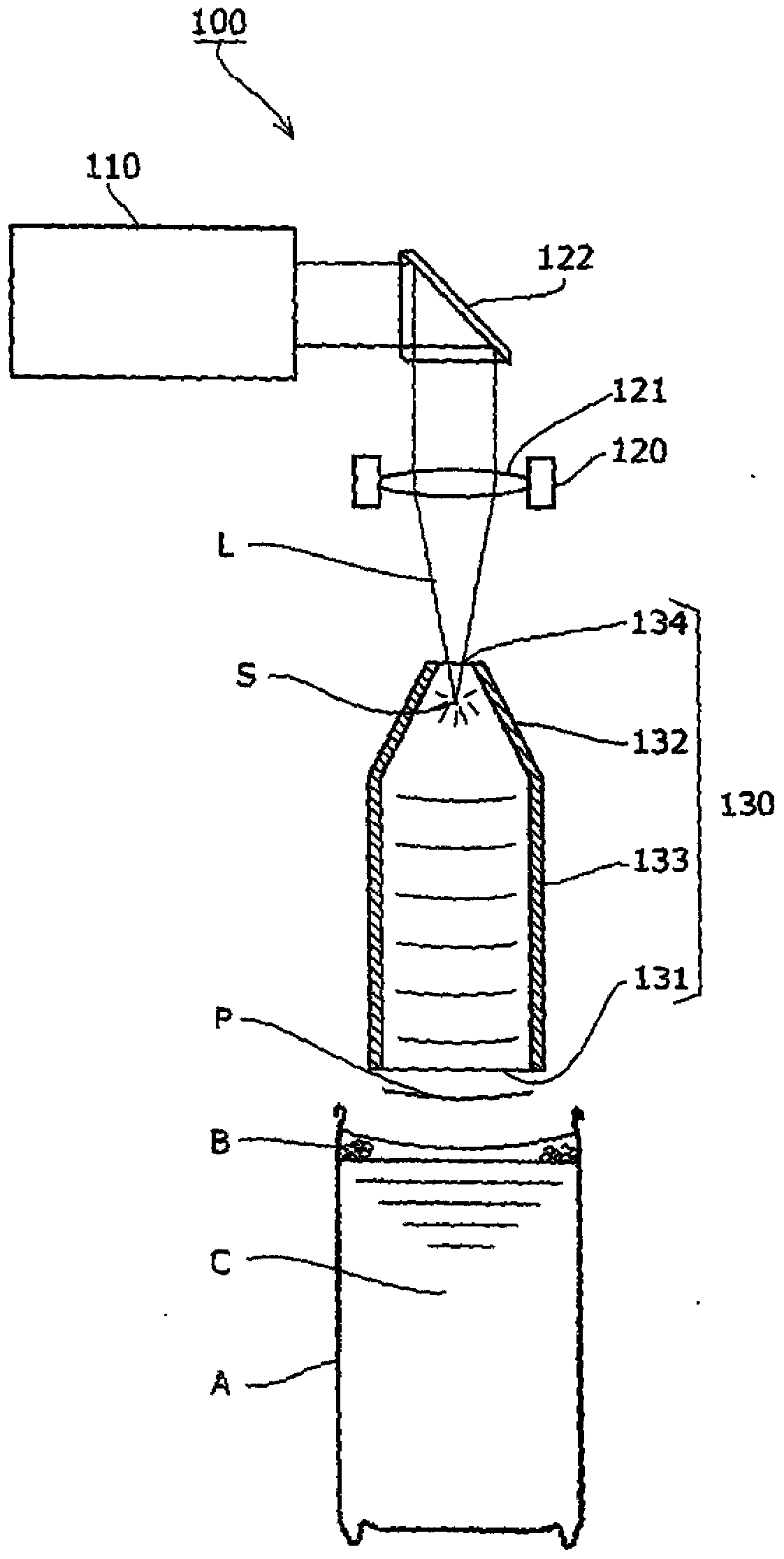

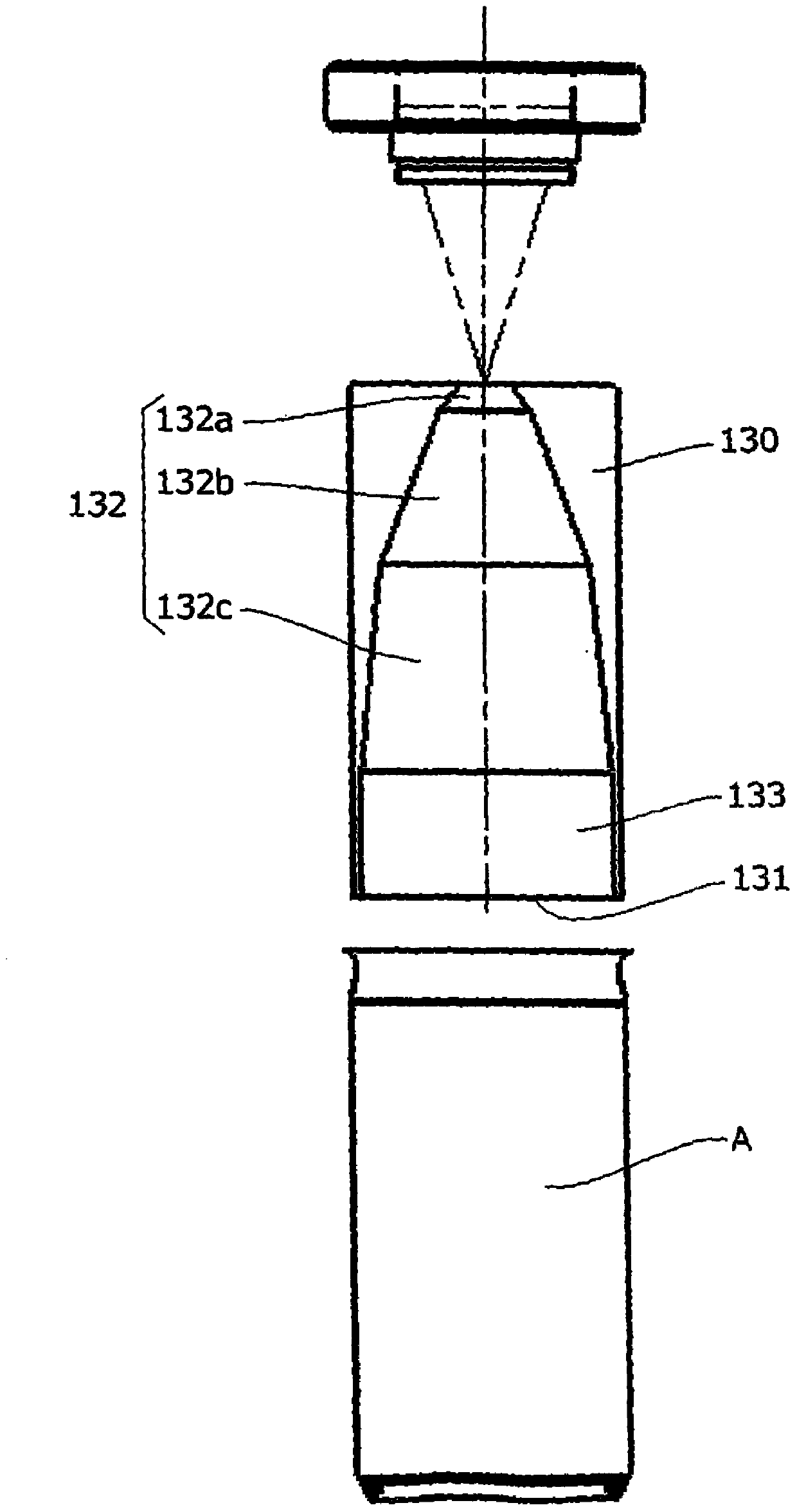

[0063] Figure 4 Another embodiment of the present invention is shown.

[0064]In this embodiment, the laser incident hole 234 is provided on the side of the tapered portion 232 of the acoustic waveguide 230, the pulse-shaped laser oscillation device 210 and the focusing optical system 220 are provided on the side, and the pulse-shaped laser light L is transmitted from the The light is illuminated from the side and concentrated toward the focal point S.

[0065] In addition, by providing the rear reflective wall 235 on the side opposite to the opening than the focal point S of the acoustic waveguide 230, the pulse-shaped sound wave P traveling from the focal point S in the direction opposite to the opening is directed toward the acoustic wave P by the rear reflective wall 235. The direction of the opening 231 is reflected and utilized as energy for defoaming.

[0066] Thereby, the utilization efficiency of energy improves further, and even if it is a low laser output, defoam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com