Hybrid biomass process with reheat cycle

A reheating and recycling technology, applied in biofuels, co-combustion mitigation, sustainable manufacturing/processing, etc., can solve problems such as reduced boiler combustion efficiency, low efficiency, and low-efficiency steam cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

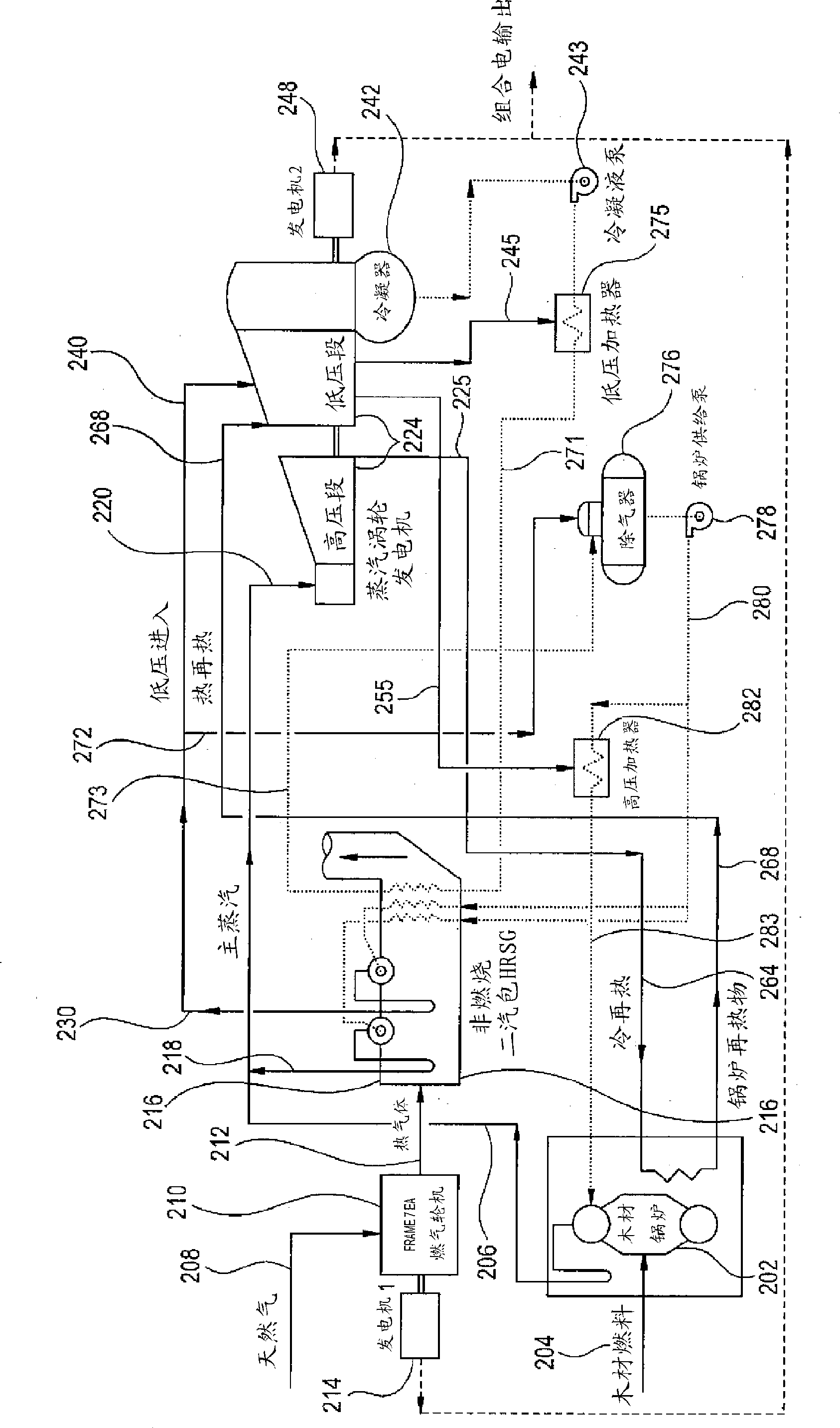

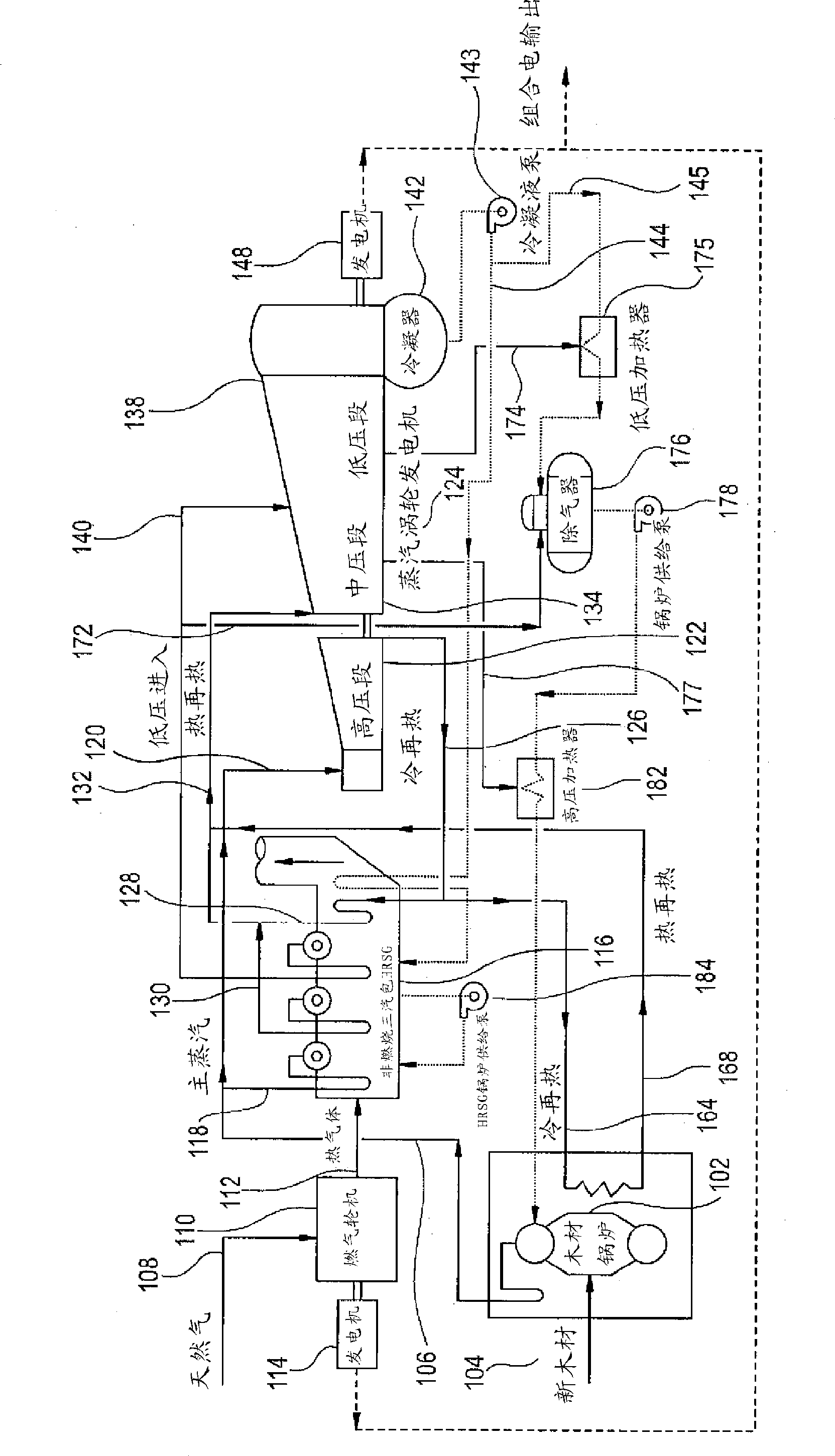

[0012] The systems and methods of the present invention allow for more efficient energy production from biomass fuels. The improved efficiency of the method is achieved by combining a typical biomass fuel cycle with a natural gas or fossil fuel cycle in a hybrid process. Steam generated from a biomass fuel cycle is combined with steam generated from a natural gas or other fossil fuel cycle, and the combined steam flow is then passed through a steam turbine generator. The proposed process burns biomass fuel separately from natural gas. The combusted gases are kept separate for post-combustion treatment before being released to the atmosphere.

[0013] in e.g. figure 1 and figure 2 In the preferred embodiment shown, the biomass fired boiler operates in parallel with a combined cycle heat recovery boiler (HRSG). This has several effects. First, the working steam pressure of the biomass boiler is no longer limited by the size of the steam turbine generator. Second, the stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com