Viscous breeding fish fry hatching mesh and hatching method

A technology of sticky eggs and mesh, which is applied in the field of fish farming, can solve the problems of low utilization rate of mesh, uneven distribution of fish eggs, and easy escape of fish eggs, so as to increase hatching efficiency, reasonable distribution of mesh, and net The effect of high chip utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

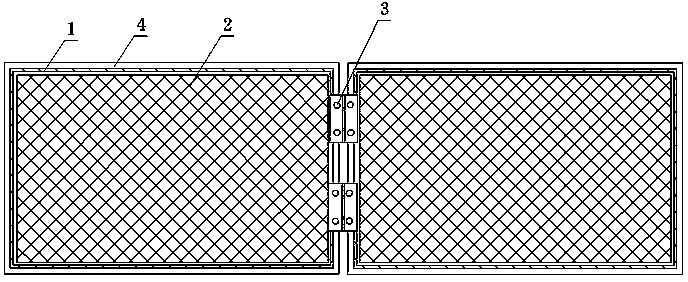

[0024] Embodiment one: see figure 1 , figure 2 , a hatching mesh for sticky eggs and fry, comprising a square frame and a mesh fixed in the square frame, the mesh consists of two identical meshes, and the two meshes are connected by hinges One body, and can rotate around the hinge shaft. The screen and the frame are fixed by Velcro.

[0025] The square frame is made of metal material, and the wire mesh is made of metal or non-metal wire mesh. The specifications of a single mesh in the mesh are 80-120cm in length and 30-50cm in width, and the mesh polyethylene material is used. The screen and the frame are fixed by Velcro.

Embodiment 2

[0026] Embodiment two: a kind of sticky ovum fry hatching mesh is basically the same as embodiment one, the difference is:

[0027] The frame of the mesh is made of non-metallic materials. The specification of a single mesh in the mesh is 80-120cm in length and 30-50cm in width. The mesh is made of polyethylene material with a mesh of 10-30 mesh. hinged connection.

Embodiment 3

[0028] Embodiment three: a kind of method for hatching sticky ovum fry, comprises broodstock cultivation, induced labor, fertilization and hatching process, hatching process, hatching process comprises the following steps:

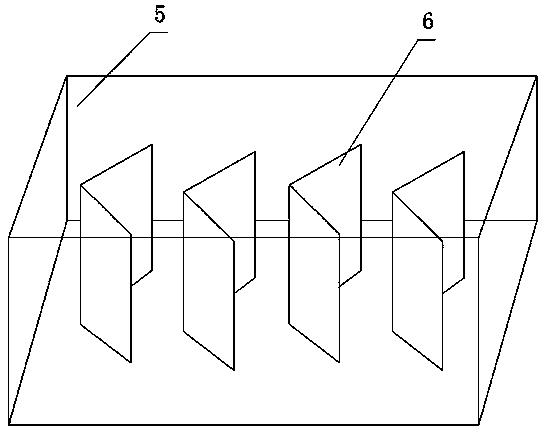

[0029] Clean and sterilize the hatching tank, unfold the mesh, spread them side by side on the bottom of the hatching tank, surround the tiled mesh with erected mesh to form a closed box with an open upper end;

[0030] Fill the hatching tank with water until the water surface is 4-8cm higher than the upper edge of the vertical mesh; put the fertilized fish eggs into the box, let the fertilized fish eggs sink freely after stirring, and spread the fertilized fish eggs on the bottom mesh , evenly distributed; then let it stand for 30-40 minutes, turn over the net at the bottom, lay it flat, put in the fertilized fish eggs again, the method is the same as the first time; let it stand for 30-40 minutes, and cover the bottom with fertilized fish eggs Take out t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com