High vegetable pickling production process

A production process and high vegetable technology, which is applied in the field of food processing, can solve the problems of poor taste, large environmental pollution, perishable deterioration and other problems, and achieve the effect of non-perishable deterioration, low nitrite content, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

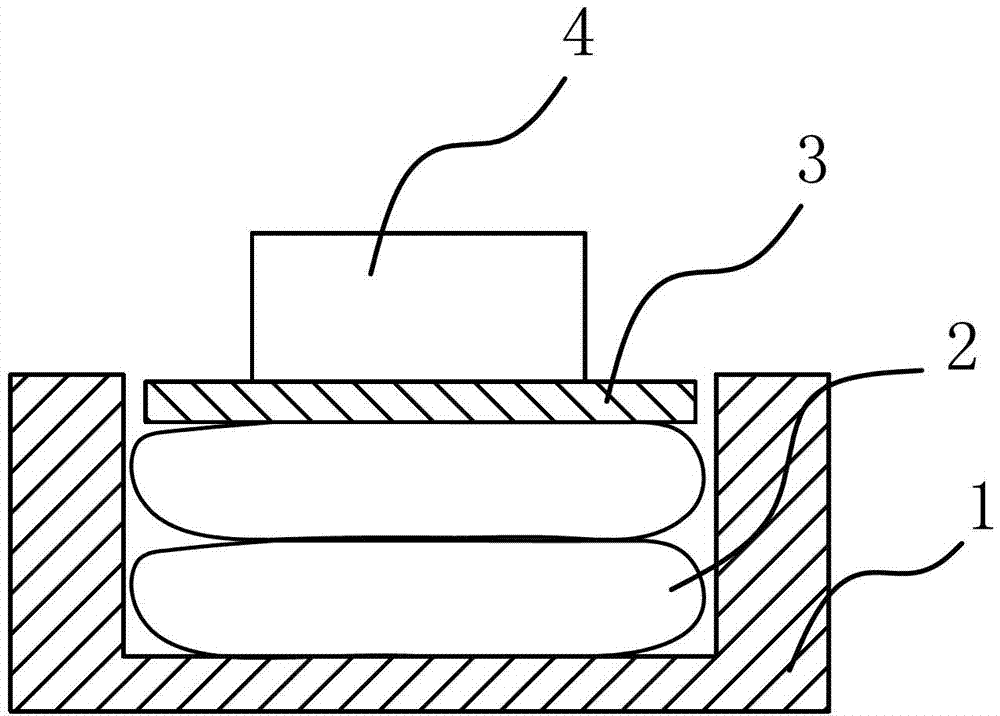

[0026] Such as figure 1 As shown, the pickling production process of this vegetable comprises the following steps: A, raw material pretreatment: remove yellow leaves, rotten leaves, broken leaves and mud from fresh vegetable, then cut flat roots, air-dried and dehydrated, so that the dried vegetable is ready for use; B. Pickling: put the flattened high vegetables layer by layer in the pickling bag body 2 made of flexible materials and placed in the pickling pool 1, put a layer of flattened high vegetables in each yard and evenly sprinkle the mixed pickling material, and The shriveled high vegetables and mixed marinade are put in at a weight ratio of 100:10-20. The mixed marinade includes salt and turmeric powder and the weight ratio of salt to turmeric powder is 100:3-8. After stacking, put the pickled bag 2. Seal and press tightly. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water activity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com