Handrail end circular arc punching and forming device

A technology of arc and end, which is applied in the field of arc punching and forming devices at the end of railings, can solve problems such as deformation of pipe ends, and achieve the effects of compact mold structure, simplified design work, and convenient manufacturing and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

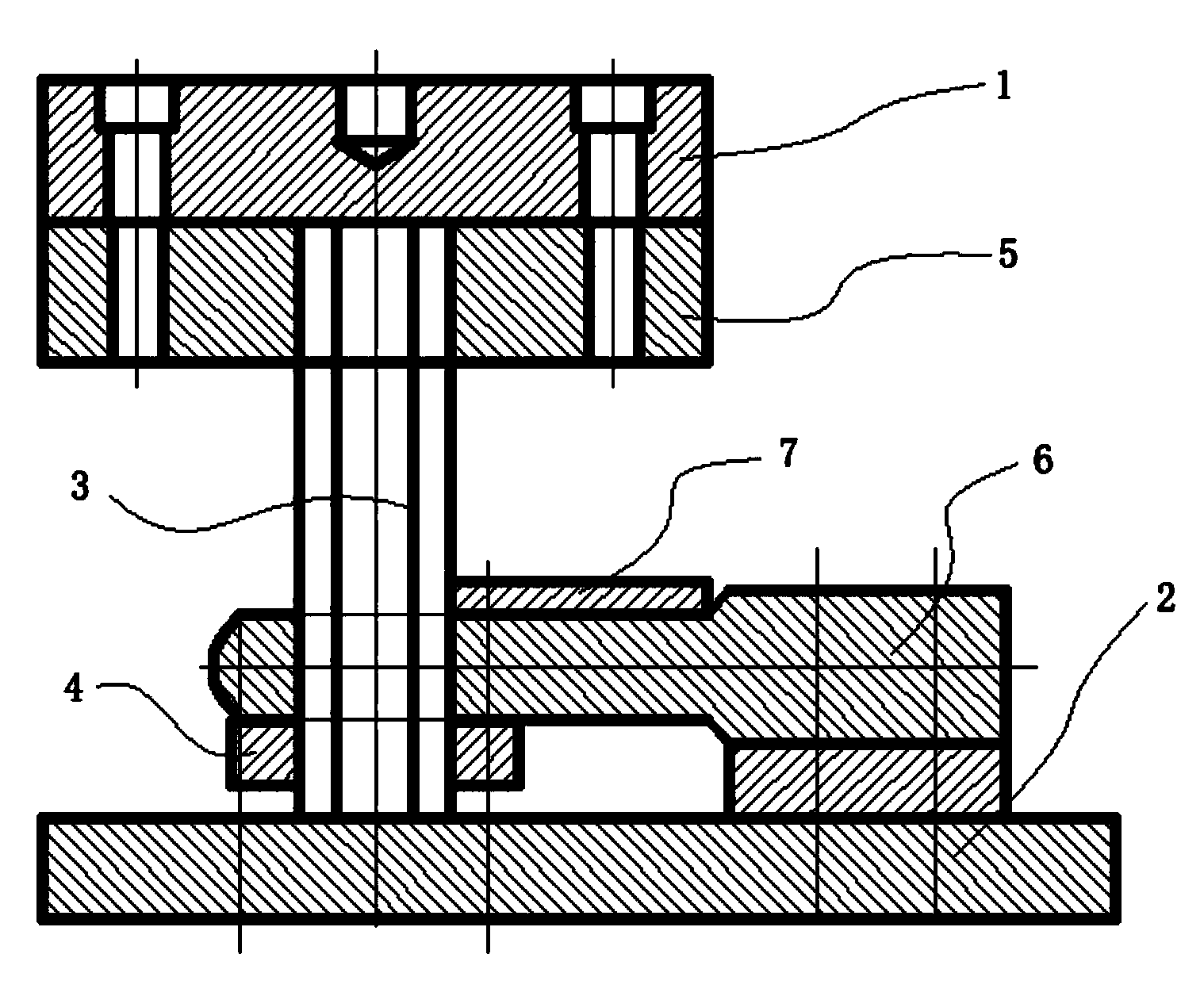

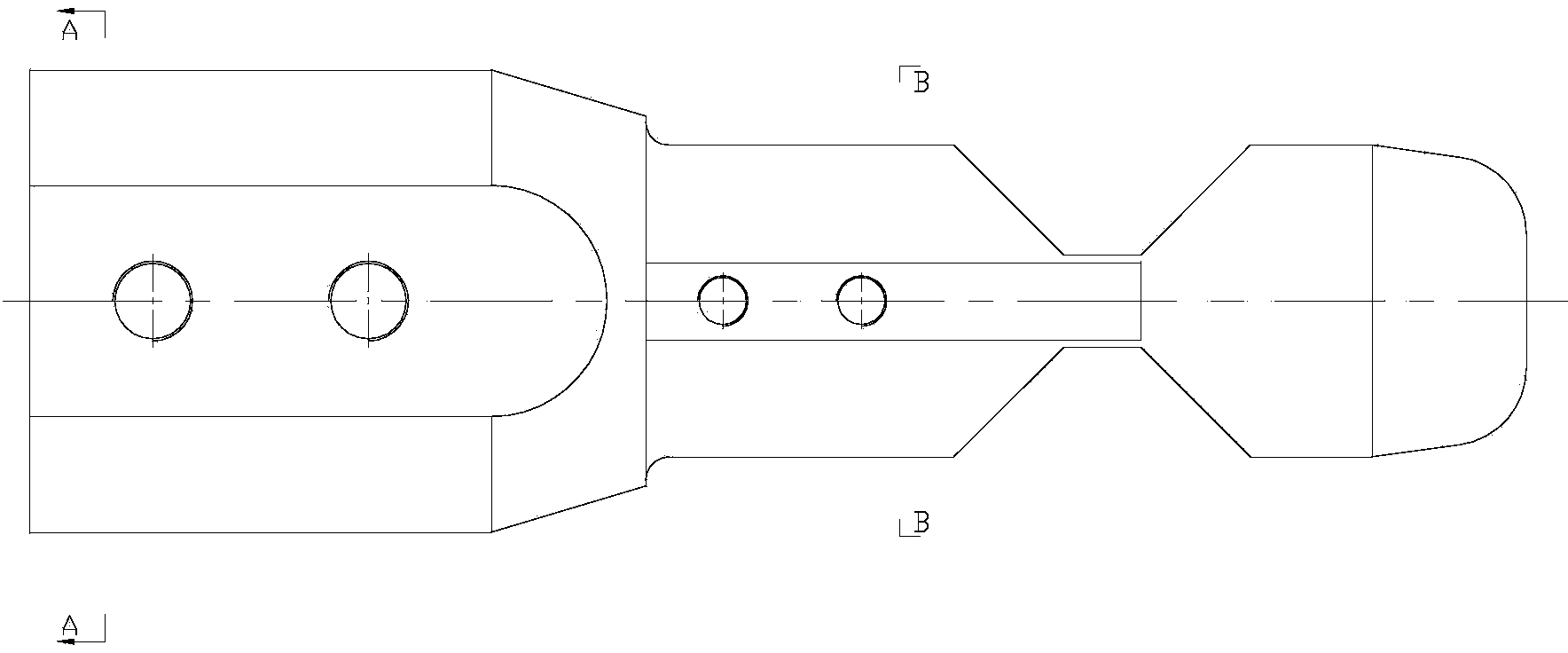

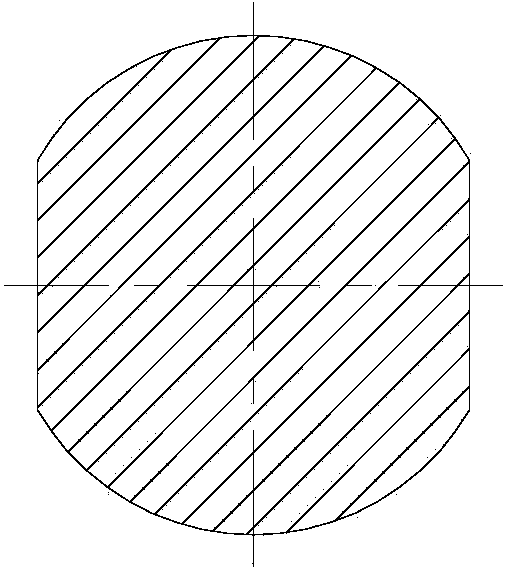

[0013] This embodiment provides a circular arc punching and forming device at the end of a railing, such as Figure 1 to Figure 4 As shown, it includes an upper mold base 1, a lower mold base 2 and an arc punching mechanism installed between the upper mold base and the lower mold base. The arc punching mechanism consists of a punch 3, a supporting die 4, a punch The fixed plate 5 and the support mold core 6 are composed, the punch fixed plate 5 equipped with the punch is arranged on the upper mold base 1, the support mold core 6 is installed on the lower mold base, and the punch 3 is vertically arranged above the support mold core, The support die 4 is fixedly arranged under the support core, and the support die 4 and the punch 3 are on the same vertical line; a stop plate 7 is also provided on the support core to control the punching of the railing pipe fittings position to ensure the accuracy of punching.

[0014] The arc at the end of the pipe adopts the support core and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com