Automatic vortex-type filtering device

A filter device, swirl-type technology, applied in the direction of filter separation, gravity filter, loose filter material filter, etc., can solve the problems of poor work reliability, high energy consumption, complex equipment structure, etc., to achieve convenient manufacturing and maintenance, The effect of low operating cost and simplified internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] Such as Figure 3-6 shown.

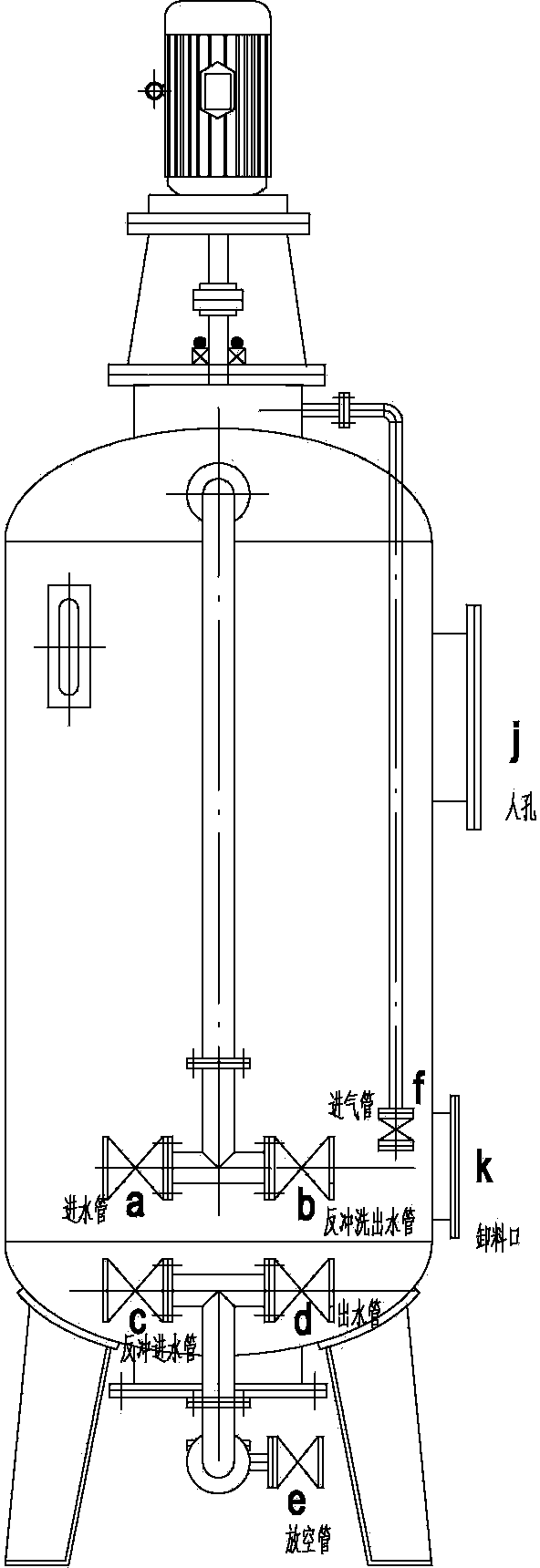

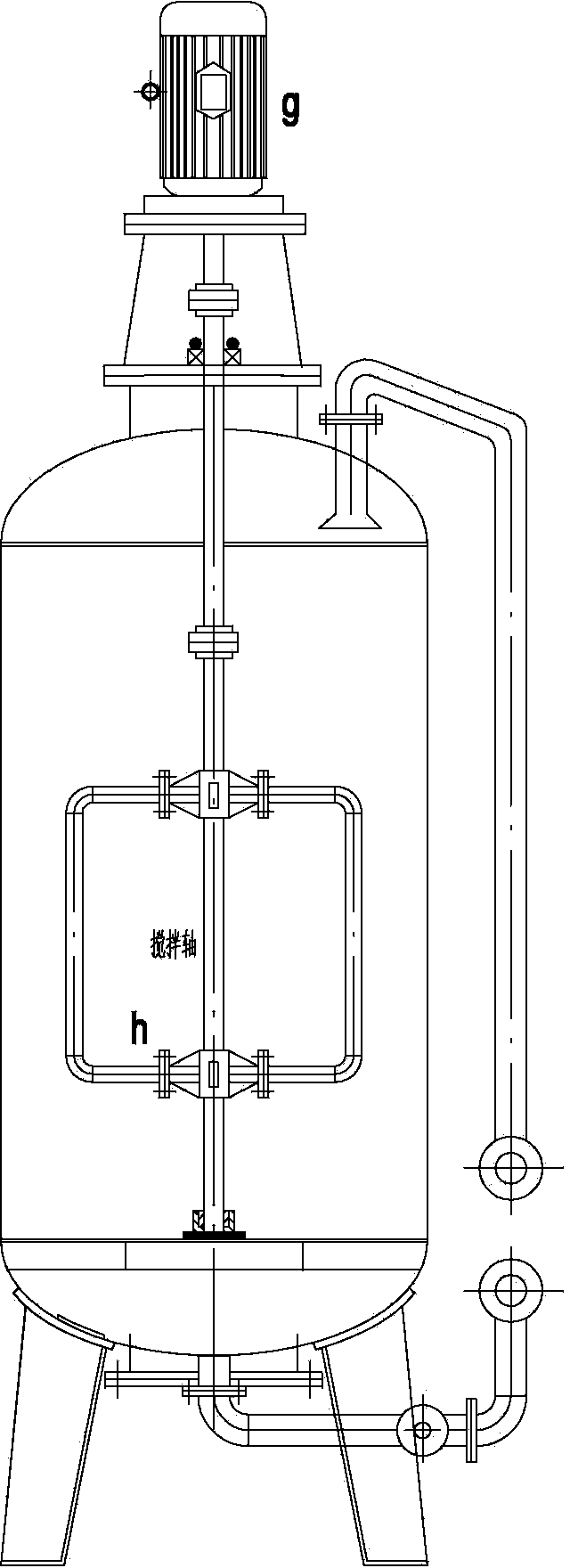

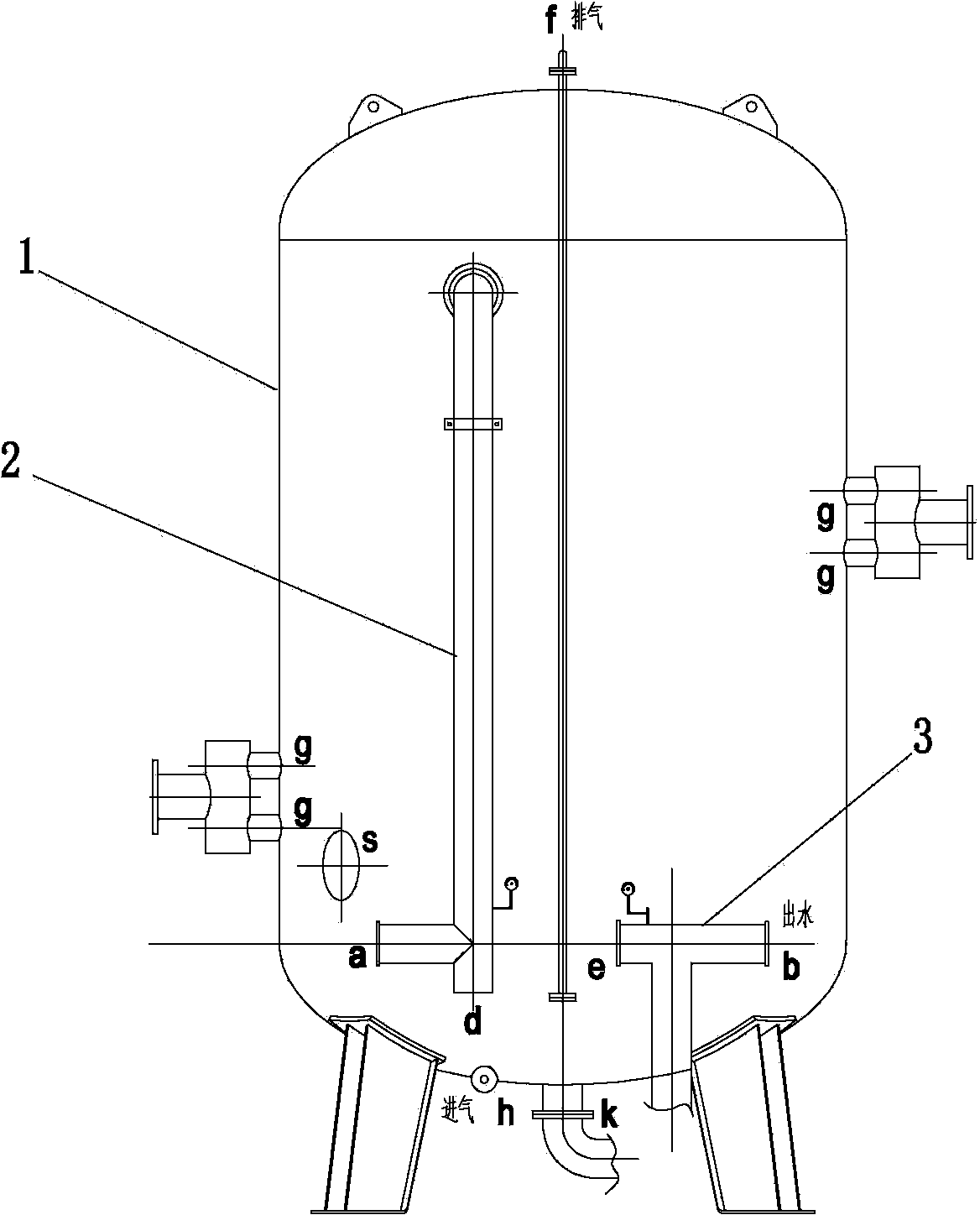

[0027] An automatic swirling filter device, which includes a tank body 1 equipped with fiber balls, a water inlet pipe 2 and a drain pipe 3, and the tank body 1 is provided with a manhole j ( Figure 4 ), the discharge port s, the exhaust port f, the vent port k, and the air inlet h are connected to the compressor, and the exhaust port f is connected to the atmosphere, such as image 3 As shown, the lower end of the water inlet pipe 2 located outside the tank body 1 is respectively connected to the water inlet a and the backwash outlet d through a three-way valve, wherein the water inlet a is connected to the water source to be treated, and the other end of the water inlet pipe 2 ( The water outlet at the upper end) extends into the inner cavity from the upper part of the tank body 1, and the inner cavity is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com