Circular mobile tooth and small tooth difference variable-speed drive device

A technology of variable speed transmission and less tooth difference, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., which can solve the problems of low load capacity, limitation of transmission accuracy and meshing performance of movable tooth reducer, and inability to fully meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will refer to Figure 1 to Figure 6 First to fourth embodiments of the present invention will be described. The same reference numerals for parts will be used to denote the same parts in these embodiments. Therefore, for each embodiment, repeated descriptions will be omitted, and structural differences will be focused on.

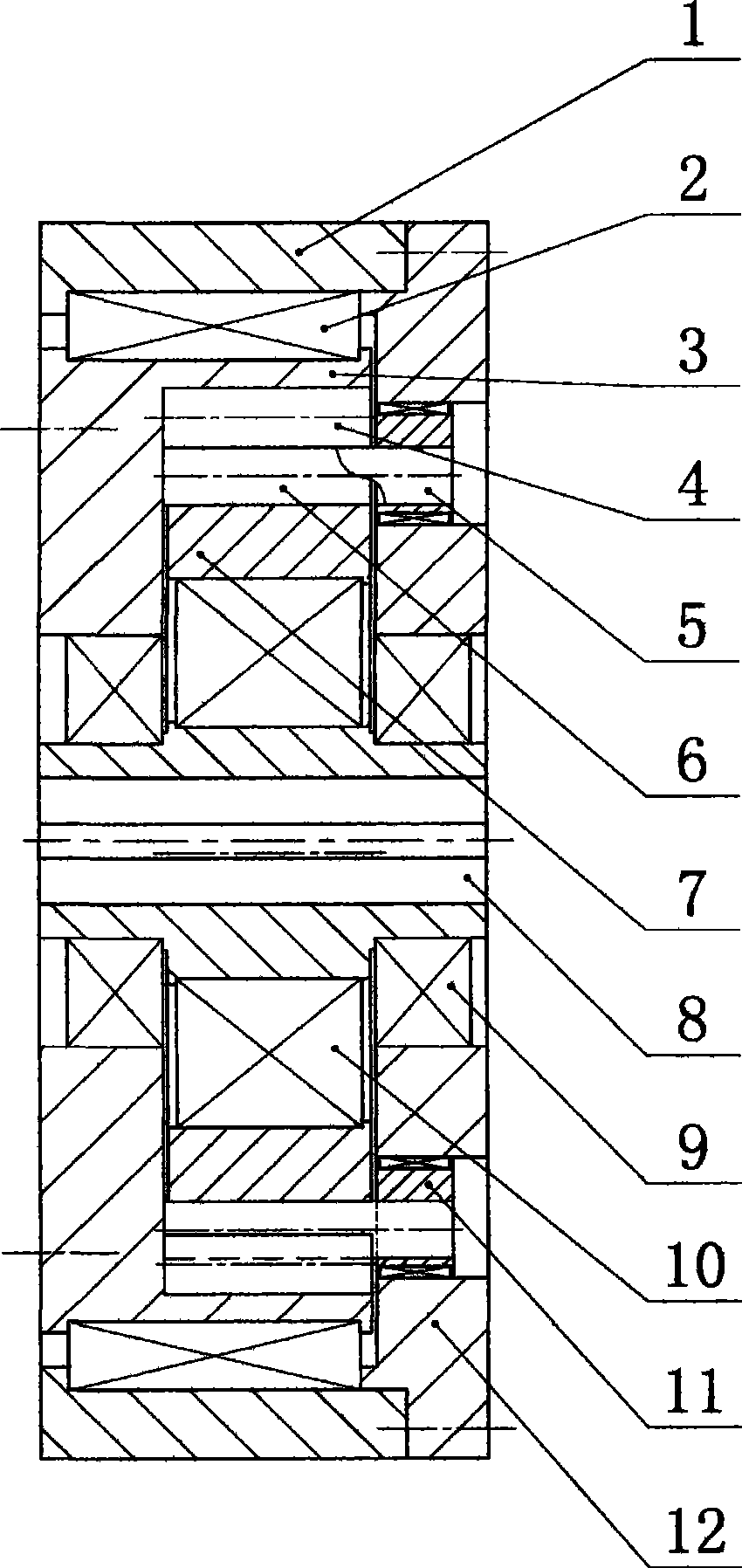

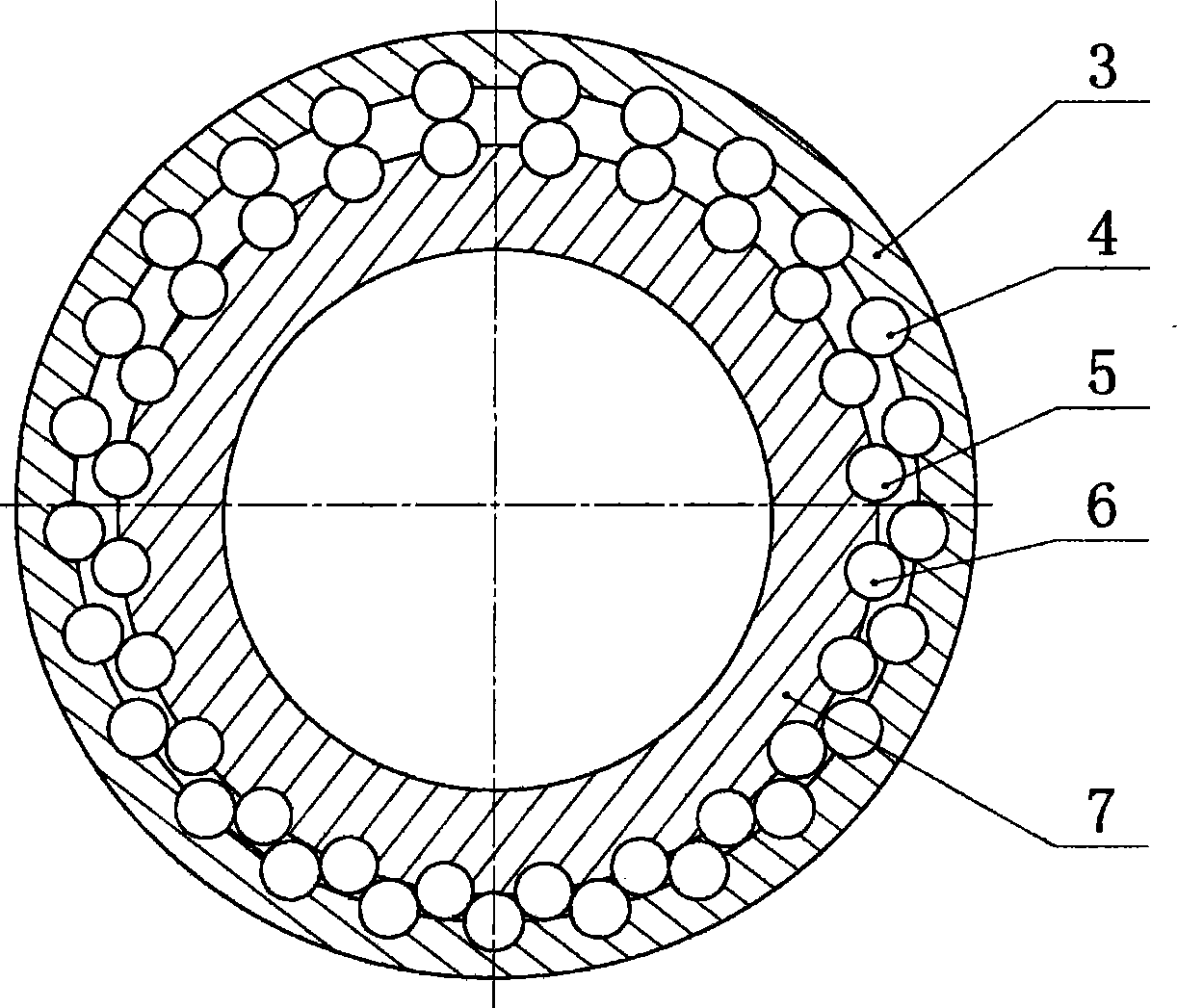

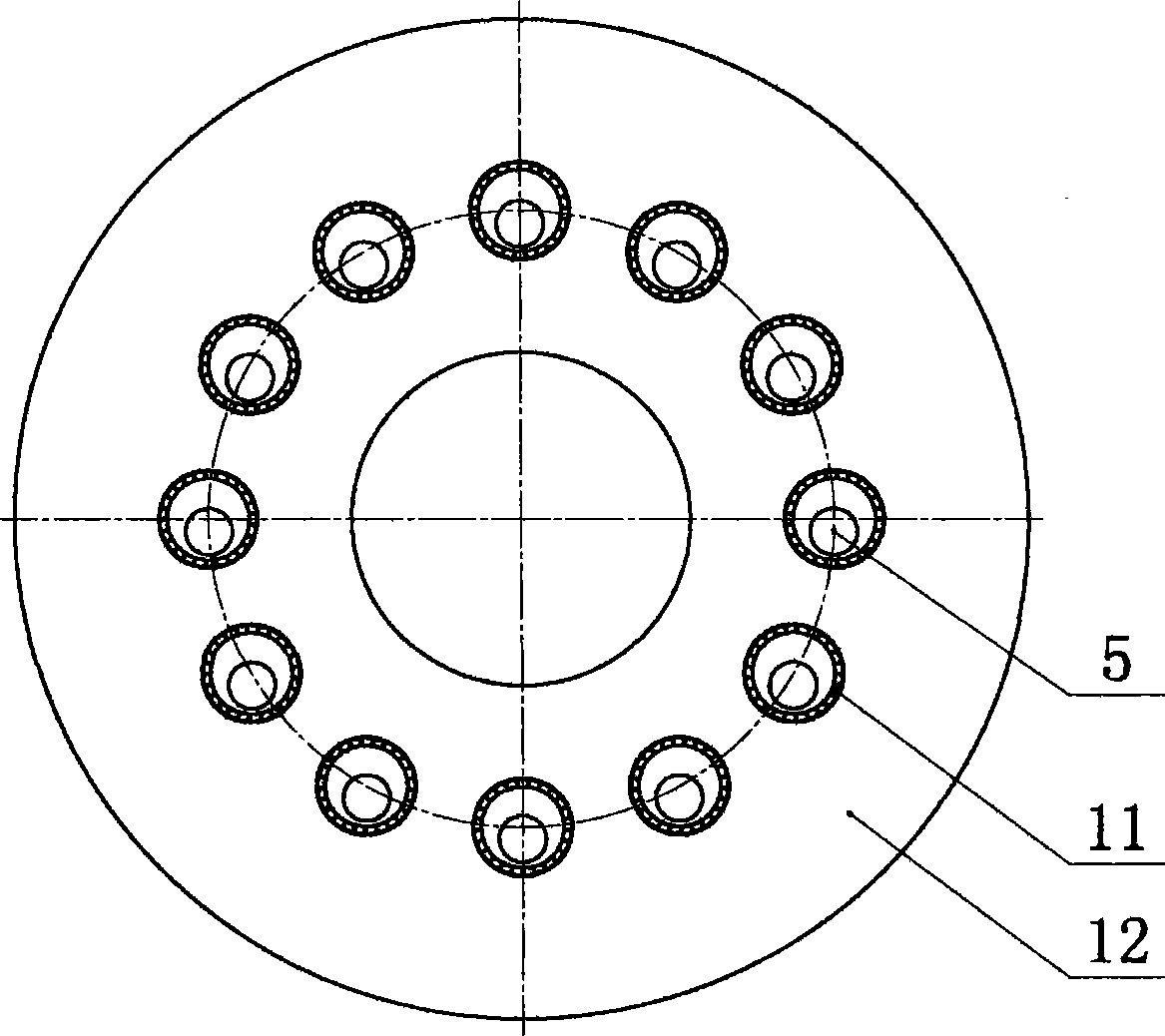

[0028] Refer below Figure 1 to Figure 3 , the figure shows the first embodiment of the present invention, the circular movable tooth less tooth difference variable speed transmission device is composed of an eccentric mechanism, a less tooth difference mechanism, and a hole pin type force transmission mechanism; the eccentric shaft 8 is supported by two bearings 9 On the transmission ring 3 and the pin hole end cover 12, the transmission ring 3 is supported on the outer ring 1 through the bearing group 2, and the inner gear ring 7 is supported on the eccentric shaft 8 through the arm bearing 10; the inside of the transmission ring 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com