Insulation curtain device capable of being opened in non-contact mode and having automatic disinfection function

A technology for automatic disinfection and thermal insulation curtains, which is applied to door/window protection devices, disinfection, water supply devices, etc., and can solve the problems of complex action sequence logic control, high cost, and complicated motor sequential action sequence logic control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The non-contact opening and thermal insulation curtain device with automatic disinfection function of the present invention will be further explained and illustrated in conjunction with the accompanying drawings and specific embodiments of the specification. However, the explanation and illustration do not constitute an improper limitation on the technical solution of the present invention. .

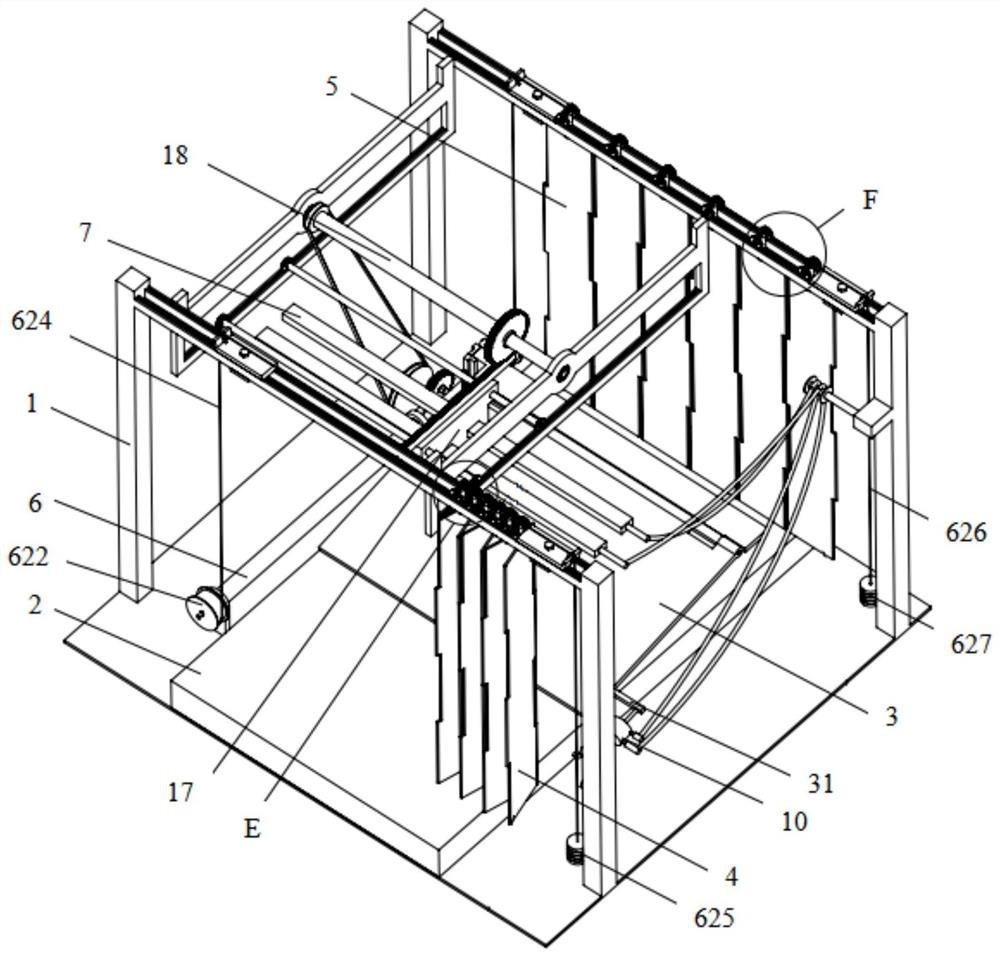

[0082] figure 1 It is a structural schematic diagram of the thermal insulation curtain device according to the present invention under a viewing angle in an embodiment.

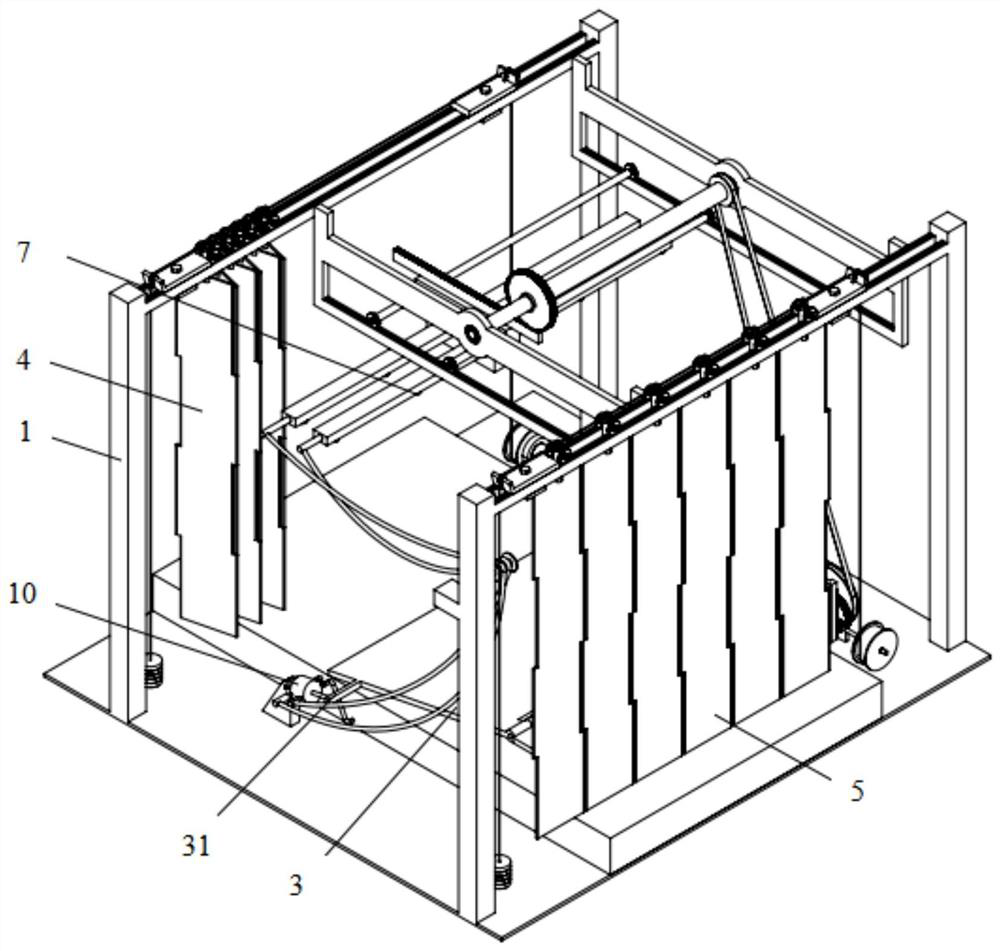

[0083] figure 2 It is a structural schematic view of the thermal insulation curtain device according to the present invention under another perspective in one embodiment.

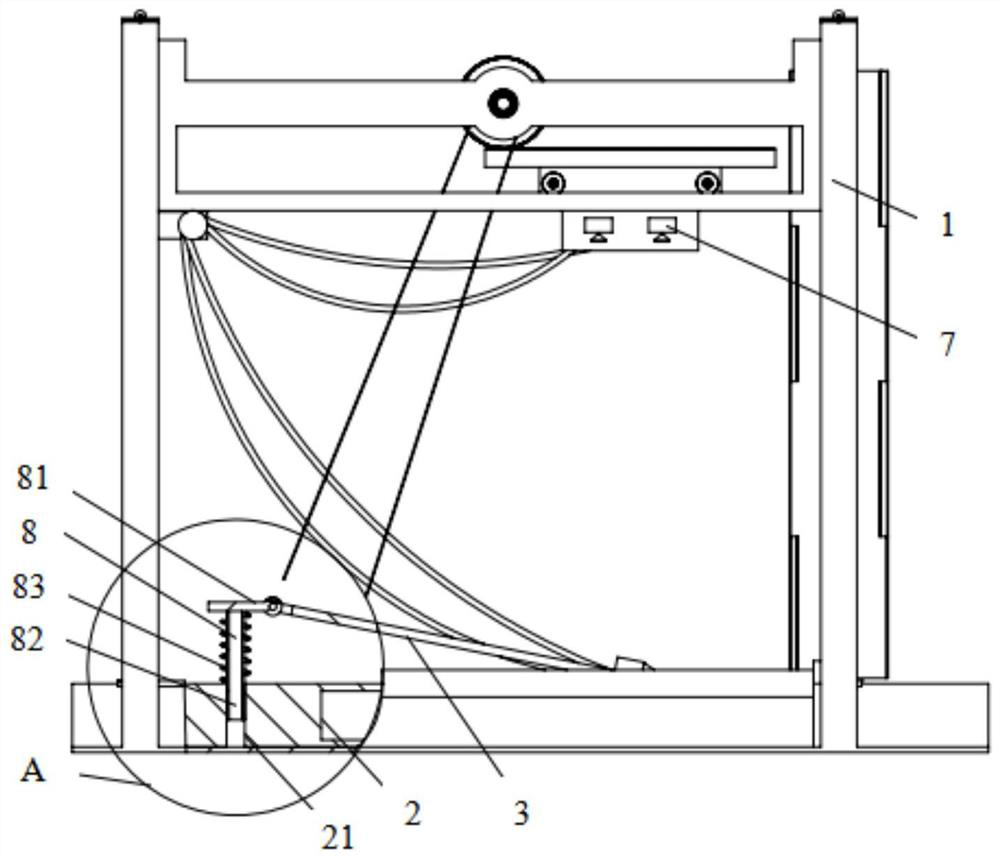

[0084] Such as figure 1 and figure 2 As shown, in this embodiment, the thermal insulation curtain device of the present invention may include: a main body frame 1, a base 2, an inclined pedal 3, a first thermal insulation curtain assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com