Test tube labeling machine

A labeling machine and test tube technology, applied in the field of labeling devices, can solve problems such as difficulty in maintaining barcode consistency, unsightly barcode stickers, and cumbersomeness, and achieve the effects of high practicability, convenient and efficient operation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below in conjunction with accompanying drawing:

[0033] The test tube labeling machine of the present invention is a supporting device of a barcode printer, and its purpose is to solve the problem that the barcode printer cannot directly label.

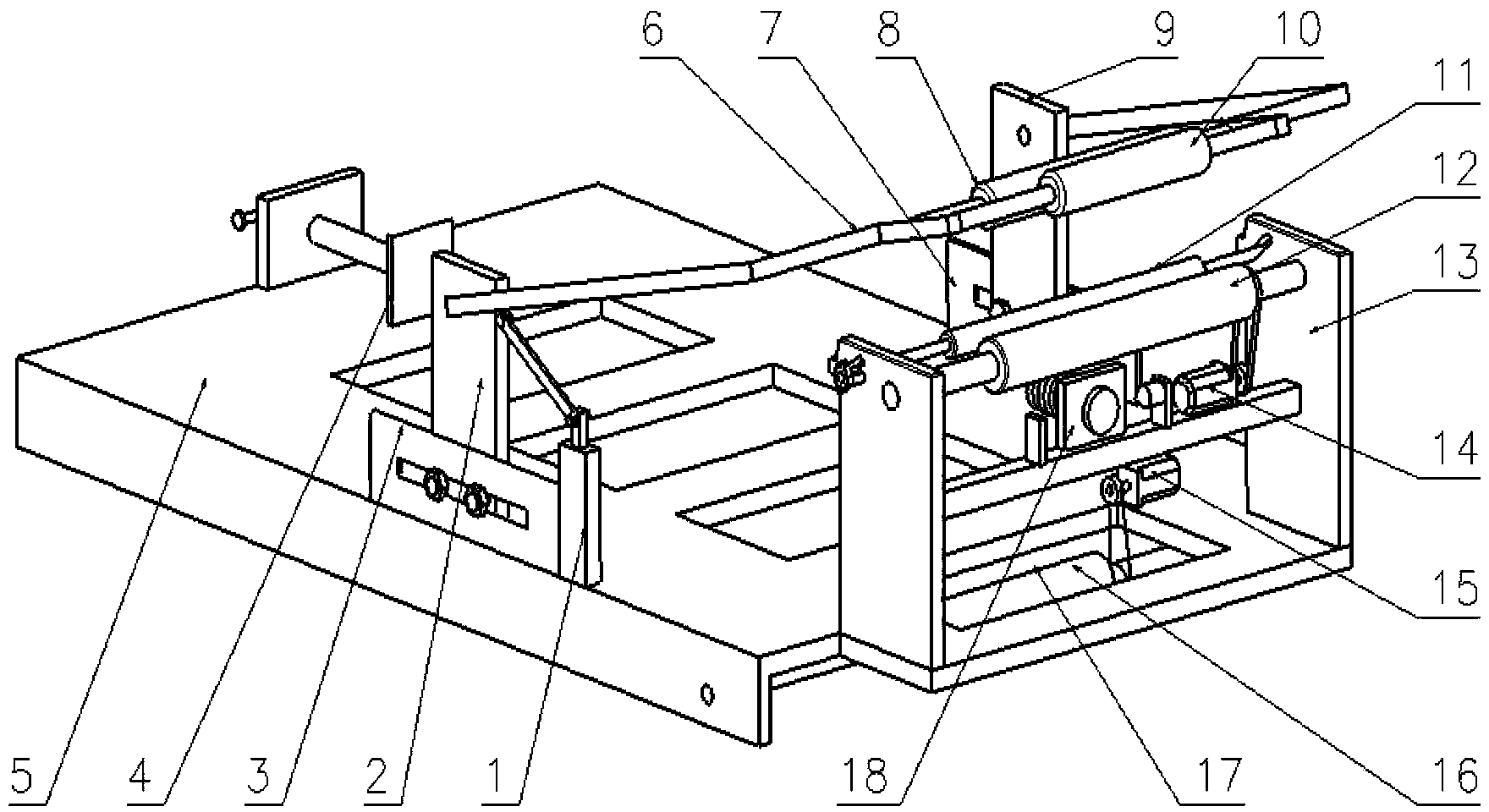

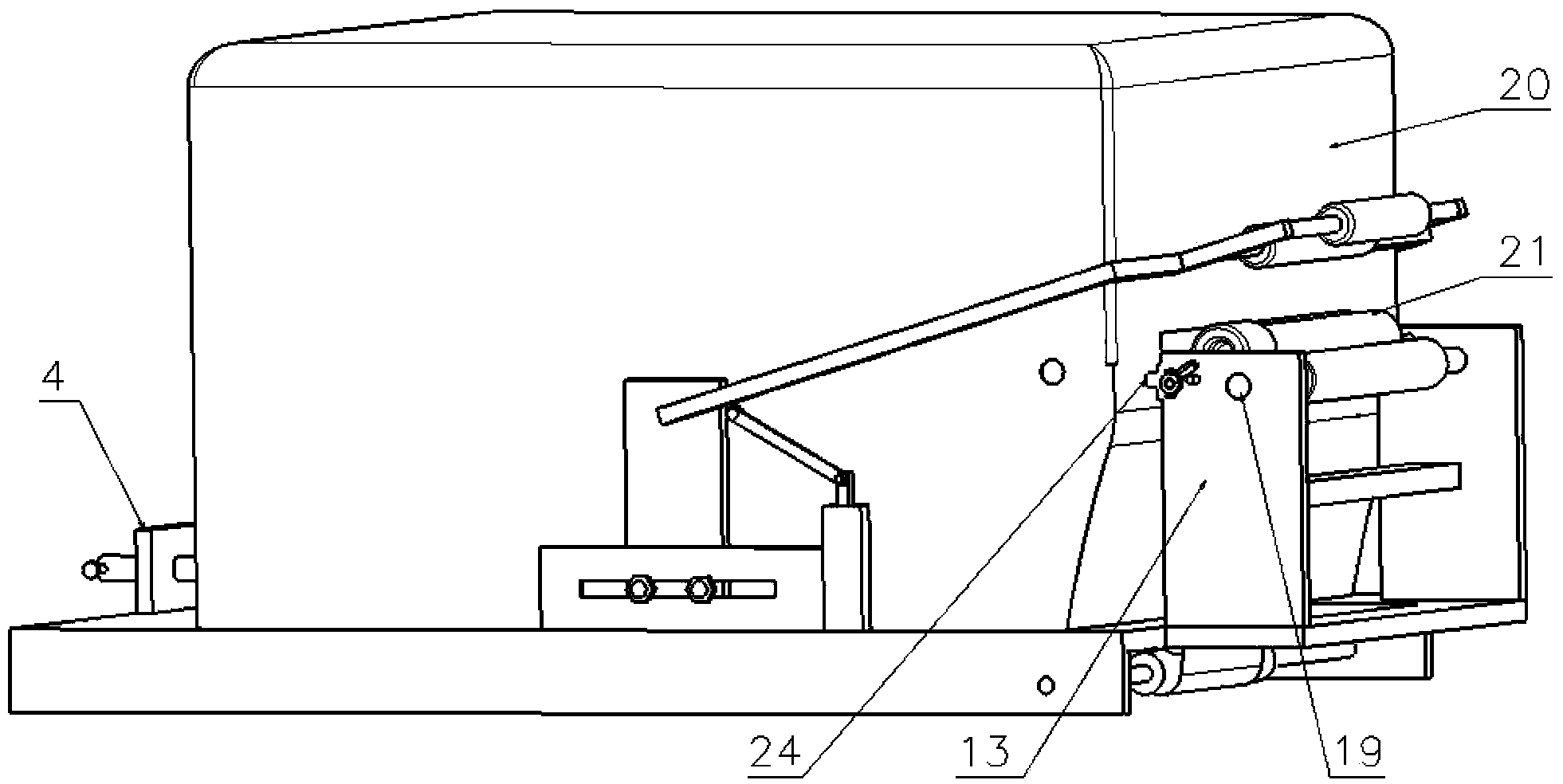

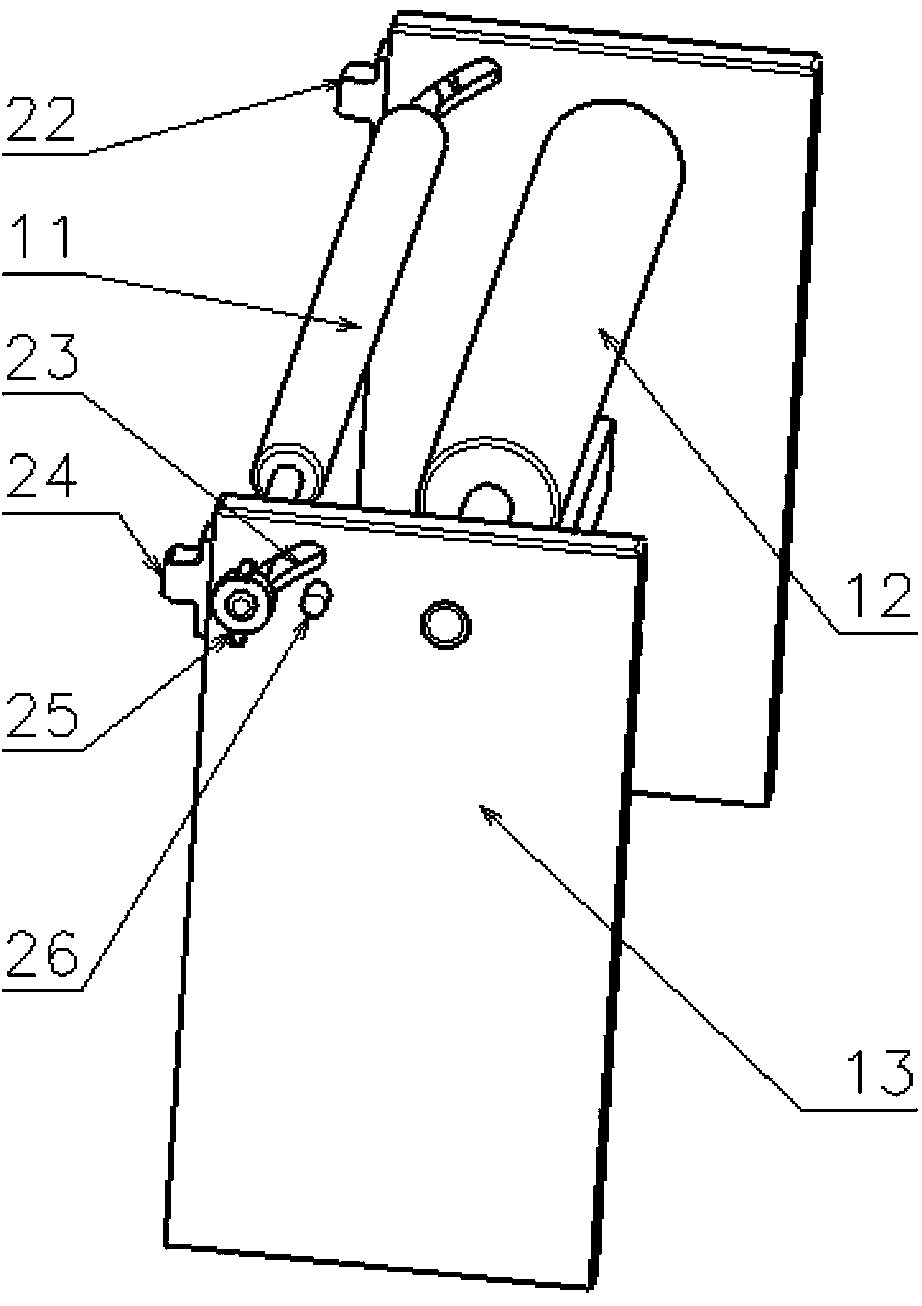

[0034] A test tube labeling machine is mainly composed of a pressure roller mechanism, a main and auxiliary roller mechanism, a clamping device 4 and a laser anti-loosening device 18; Roller support plate 2, No. 2 pressure roller support plate 9, pressure roller bracket 6, pressure roller 8, grip roller 10, No. 1 chute plate 3, No. 2 chute plate 7, travel switch 1;

[0035] The main and auxiliary roller mechanism is made up of main roller 12, auxiliary roller 11, main roller motor 14, rotary shaft 16, rotary shaft motor 15.

[0036] refer to figure 1 and figure 2, the two chute plates of the pressure roller mechanism, No. 1 chute plate 3 and No. 2 chute plate 7 are symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com