Box core spacer rapidly formed double-row needle water box

A technology of double rows of needles and spacers, applied in rigid containers, containers, packaging, etc., can solve the problems of many production processes and processing equipment, many workers, non-standard glue positions and glue dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

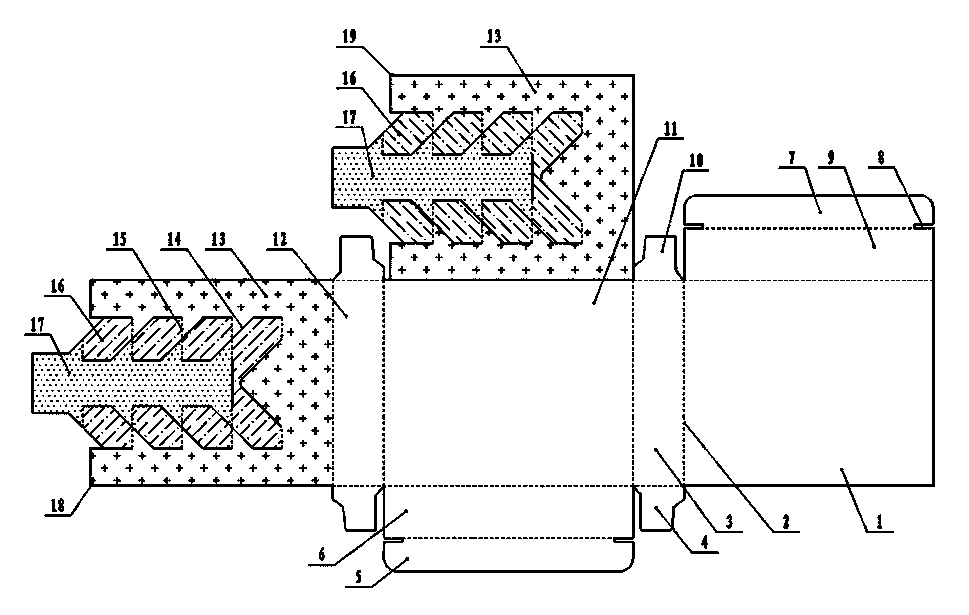

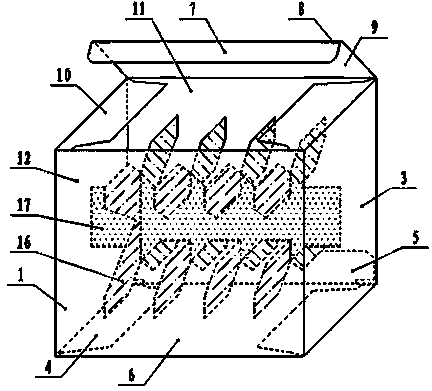

[0008] Example: such as figure 1 with figure 2 As shown, a double-row needle water box with rapid prototyping of box core spacers, the box body is composed of front 1, back 11, right side 3, left side 12, upper cover 9 and lower cover 6, on the front 1 and Indentations 2 are processed between the right side surface 3, between the right side surface 3 and the back surface 11, and between the back surface 11 and the left side surface 12. The upper cover 9 is processed above the front surface 1, and the upper cover 9 is processed above Overlock 7, between the front 1 and the upper cover 9, and between the upper cover 9 and the upper overlock 7 are processed with indentations 2, the lower cover 6 is processed under the back 11, and the lower cover 6 is processed with a lower overlock 5 , Indentation 2 is processed between the back 11 and the lower cover 6, and between the lower cover 6 and the lower overlock 5. The upper cover 10 is processed above the left side 12 and the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com