Single-row sorting machine for rhizome materials

A technology for rhizomes and materials, which is applied to the field of single-row sorting machines for rhizomes and fruits before fruit detection. It can solve the problems of irregular sorting, different numbers of arrangements, and energy consumption of large horse-drawn carts, etc., and achieves convenient speed adjustment and improvement. Detection efficiency and the effect of reducing the vacancy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

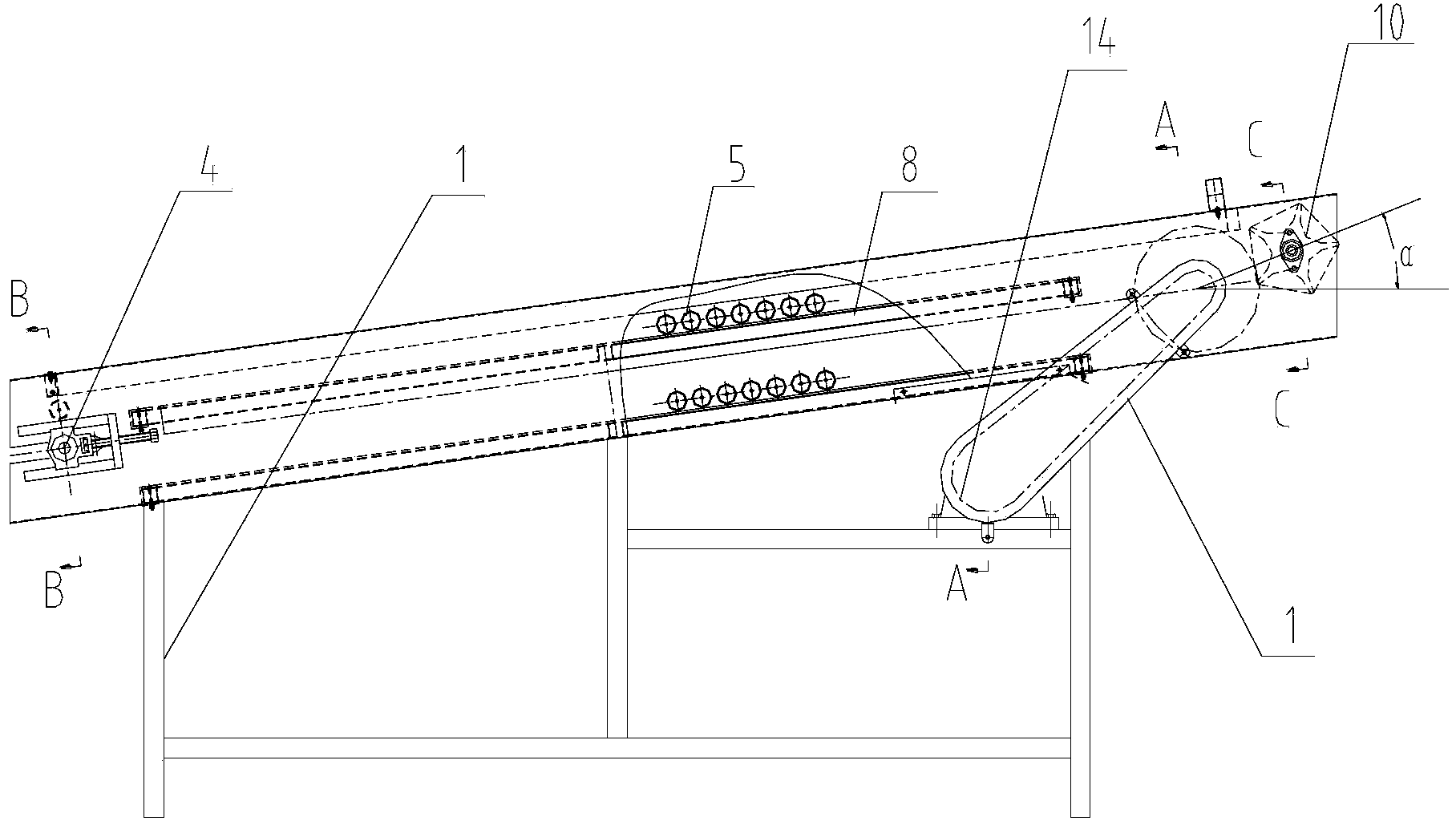

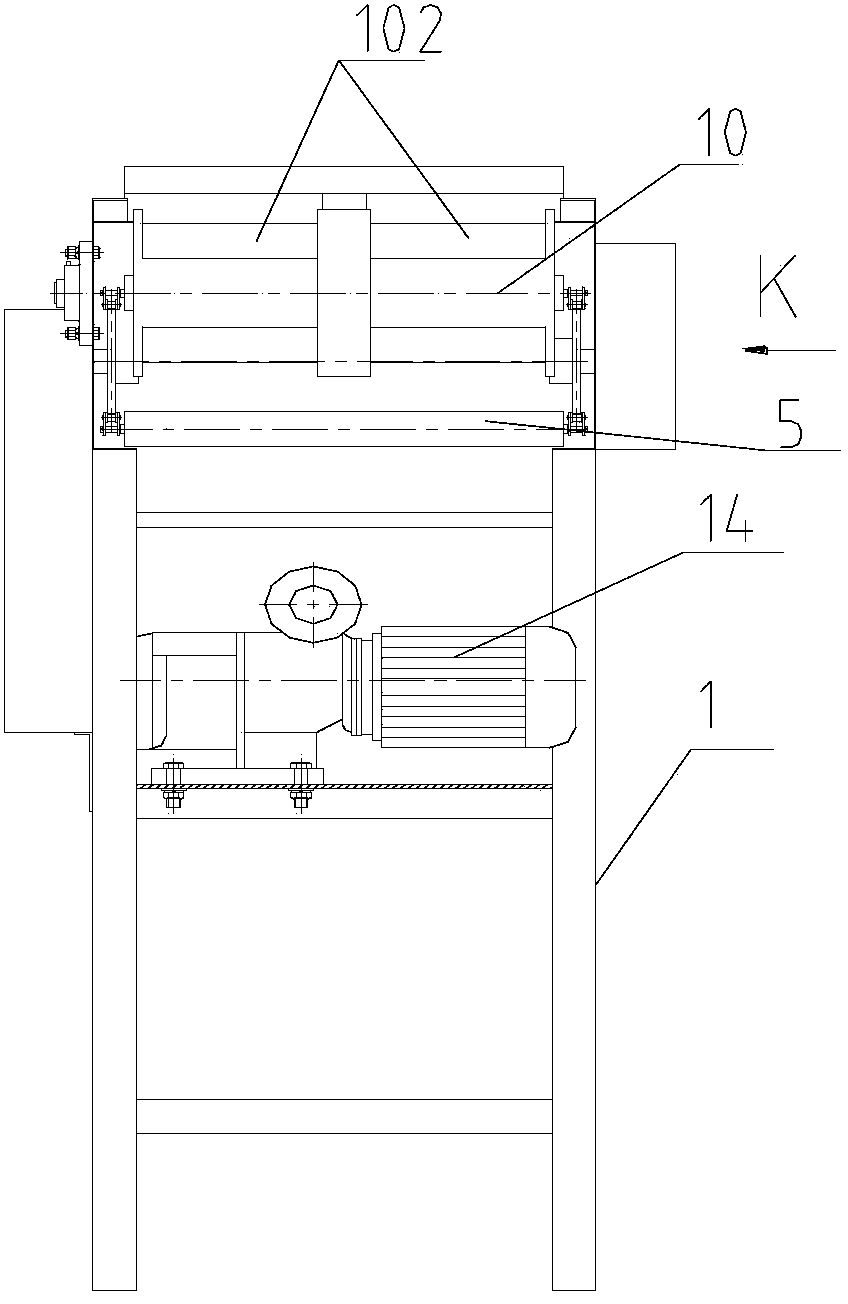

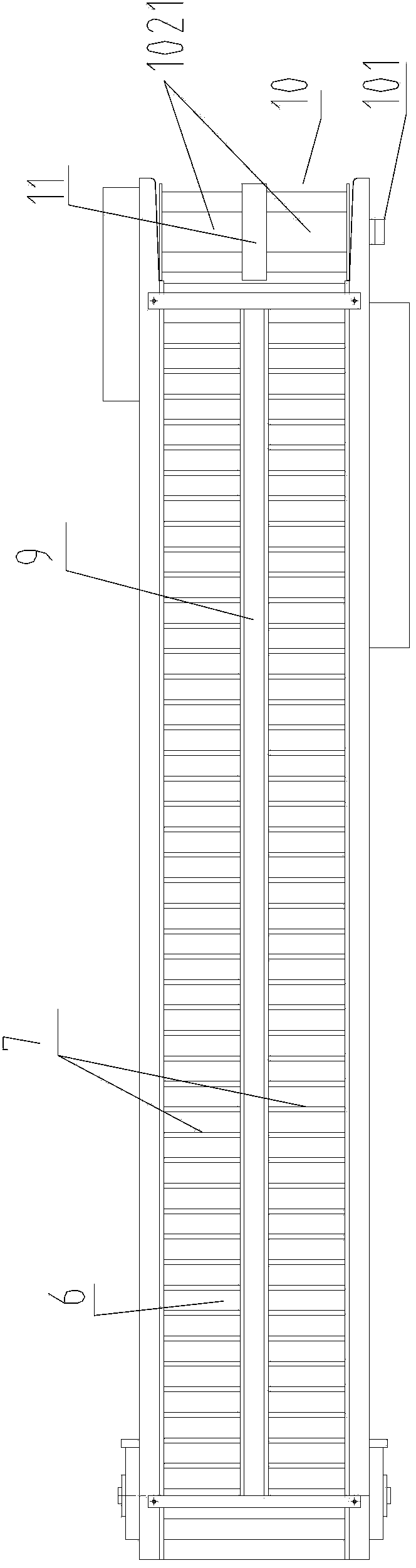

[0037] figure 1 and figure 2 It is a single row sorting machine for rhizome materials provided by the present invention, including: a frame 1, an endless chain 2, a driving shaft 3 and a driven shaft 4 arranged at the front and rear ends of the frame 1, and a plurality of racks arranged in parallel on the frame 1 The roller 5 on the top, the driving motor 14 drives the driving shaft 3 to rotate through the sprocket 13 or the direct connection mode, the driving shaft 3 drives the endless chain 2 to convey along the ring direction through the sprocket 13, and a ring chain 2 is respectively arranged at both ends of the roller 5 , The two ends of each roller 5 are fixedly connected with the endless chain 2 through pin shafts. In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com