Die-cutting machine for producing single output standing pouches

A die-cutting machine and stand-up pouch technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of offset, affecting the quality of film die-cutting stand-up pouches, and inconsistent pulling speed and tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

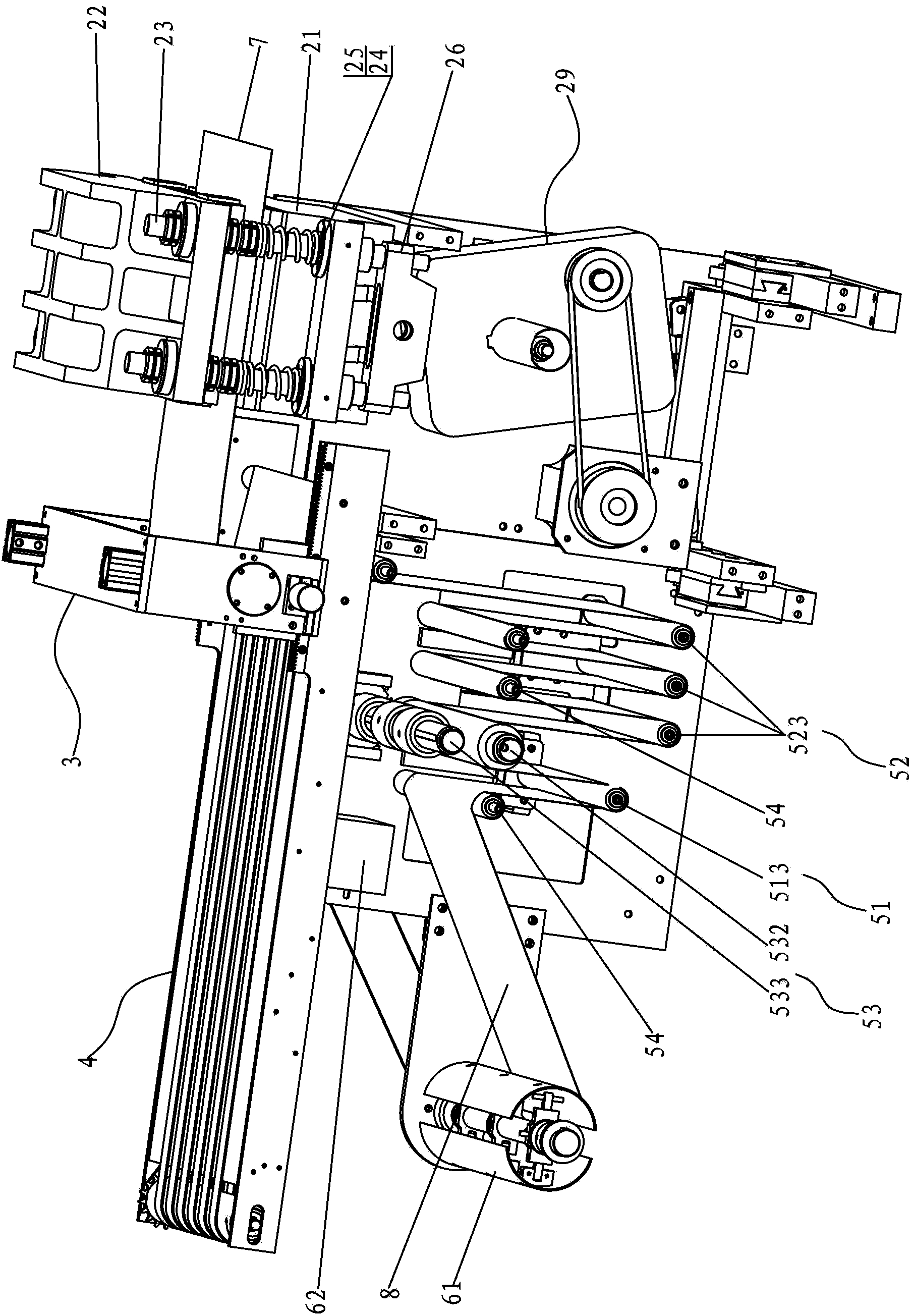

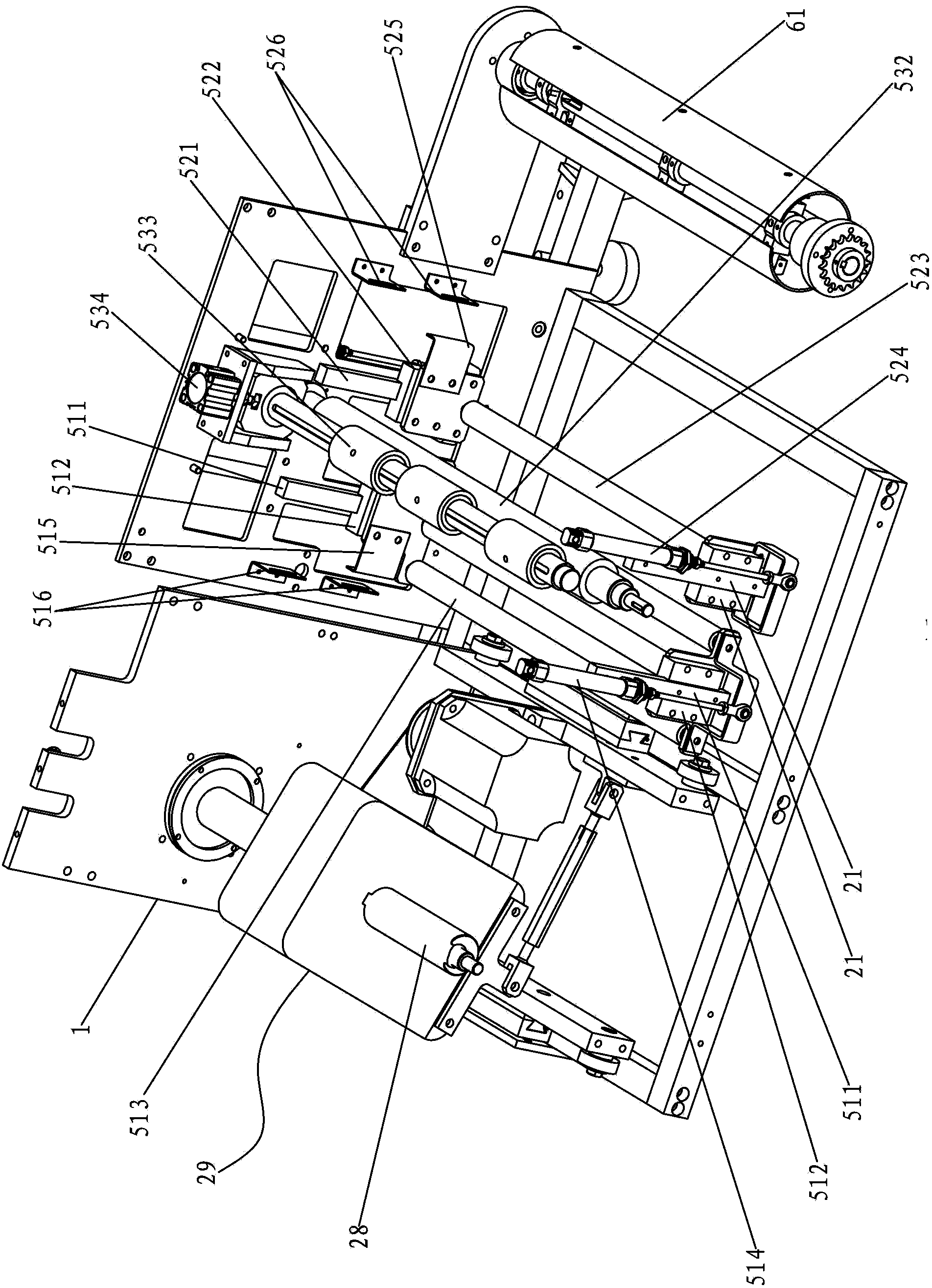

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

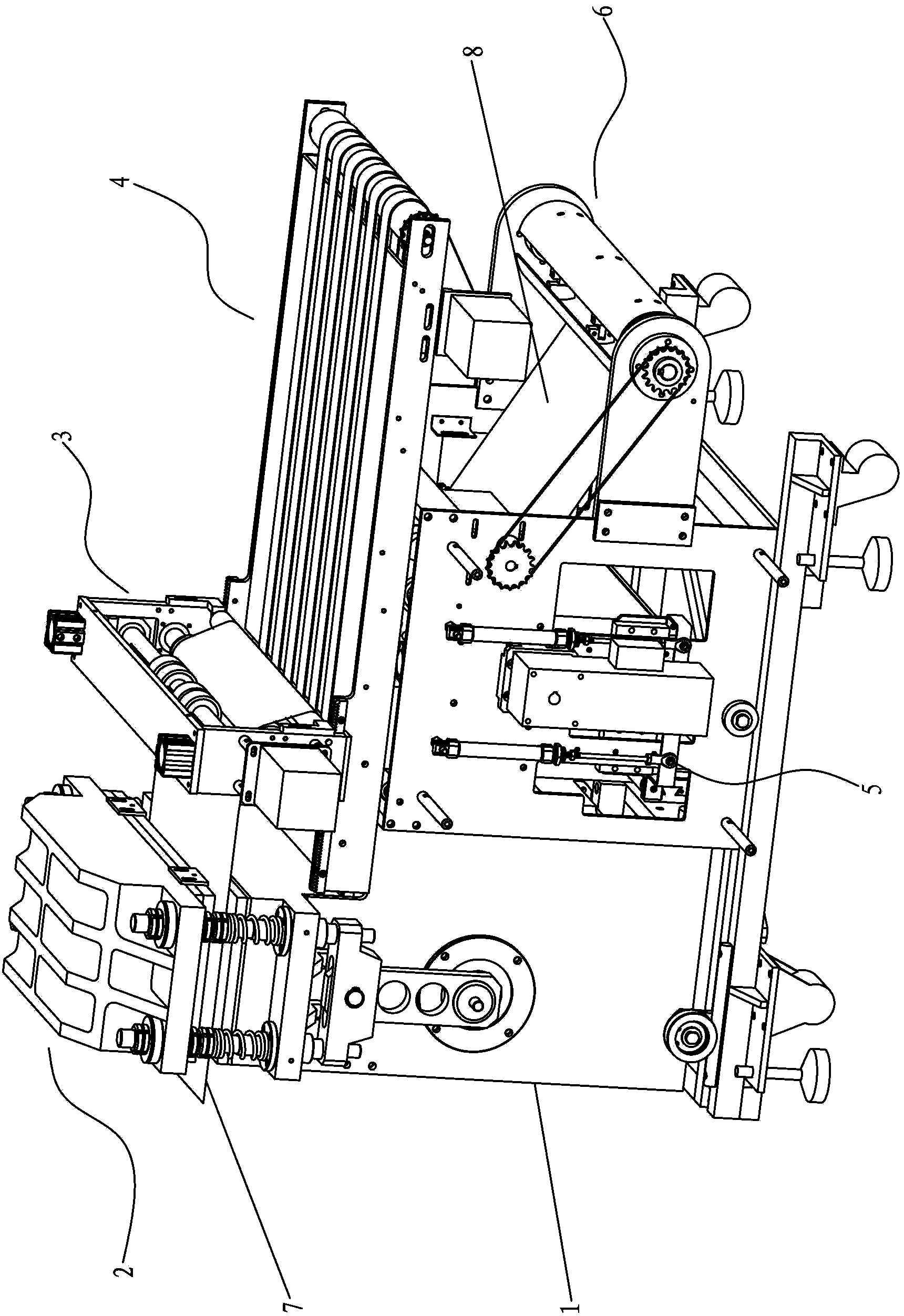

[0027] The present invention is a die-cutting machine that can be used for producing single-out stand-up pouches, not only can be used for producing ordinary special-shaped bags or one out of two stand-up pouches 9, but also can be used for producing single-out stand-up pouches 9. When producing the film 7 of two stand-up pouches 9, the film waste 8 is separated by die-cutting, and both sides of the film waste 8 are four layers; layer; when producing a single stand-up pouch 9, one side of the film 7 needs to be folded or inserted at the bottom, and after the process of folding or inserting the bottom, the film 7 on this side is four layers, and between the second layer and the third layer The intersection of the two layers of film 7 forms the bottom line 71 of the stand-up bag 9, and the film 7 on the other side has two layers.

[0028] The present in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com