System and method for detecting open angle of super-lift device

A super-lifting device and angle detection technology, which is applied in the direction of measuring devices, transportation and packaging, instruments, etc., can solve the problems of lateral force, twisting and deformation of the rotating shaft of the angle encoder, and the concentricity of the rotating support and the rotating arm. Guarantee etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

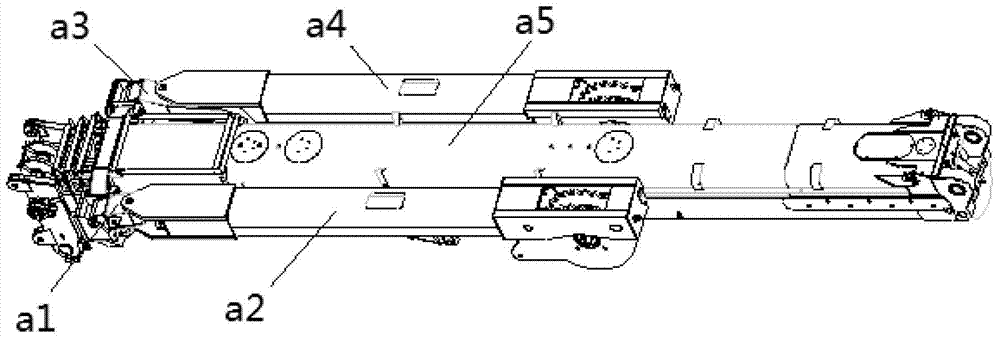

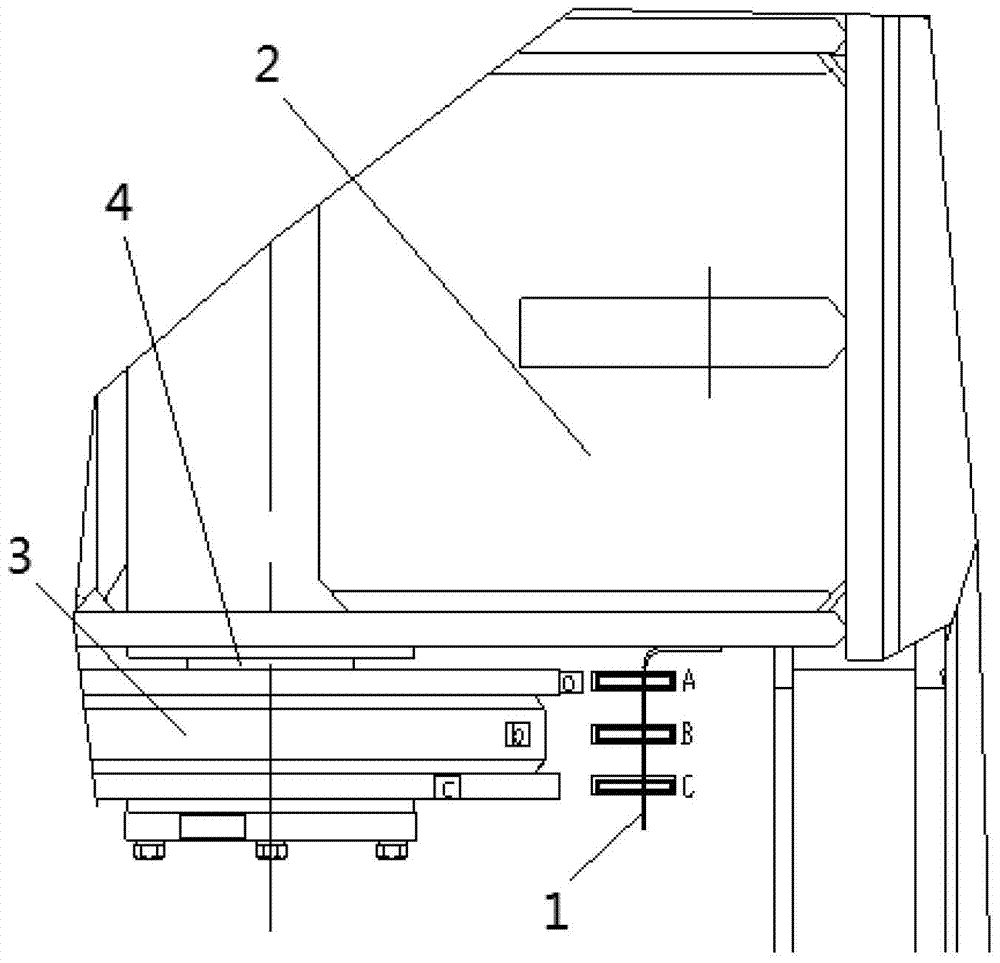

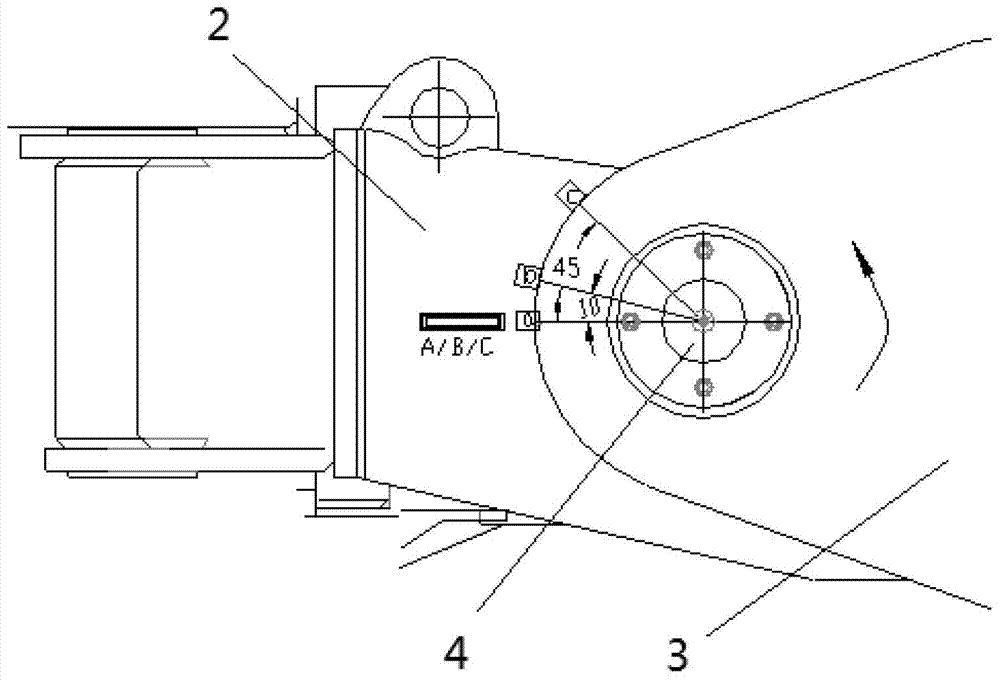

[0034] Such as figure 2 As shown, it is a schematic structural view of an embodiment of the opening angle detection system of the super-lifting device of the present invention, image 3 for figure 2 A structural schematic diagram of another angle of the embodiment. In this embodiment, the opening angle detection system of the super-lifting device includes:

[0035] Two sets of detection switch mounting brackets are respectively fixedly installed on the left rotating support and right rotating support of the super lifting device;

[0036] Two groups of proximity switches are respectively fixedly installed on the two groups of detection switch mounting brackets, and each group of proximity switches includes a plurality of proximity switches;

[0037] Two groups of detection blocks are respectively fixedly mounted o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com