A device for dehydration and drying treatment

A drying treatment and operation technology, which is applied in the directions of drying gas arrangement, drying solid materials, local stirring dryer, etc., to achieve effective dehydration and drying treatment and stable dehydration and drying treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

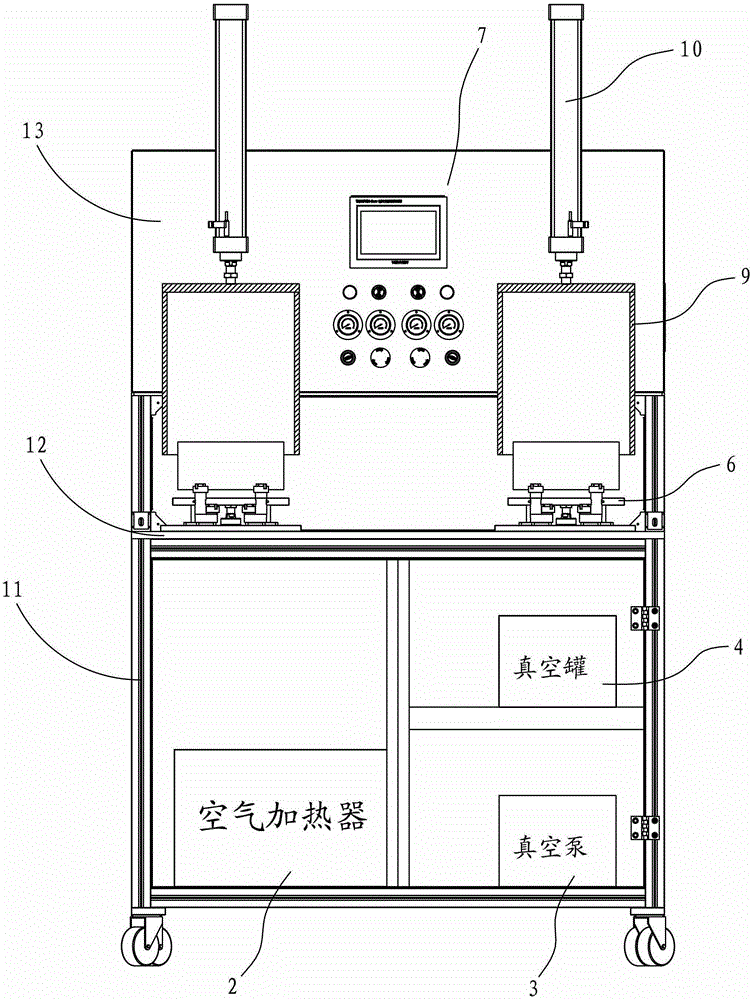

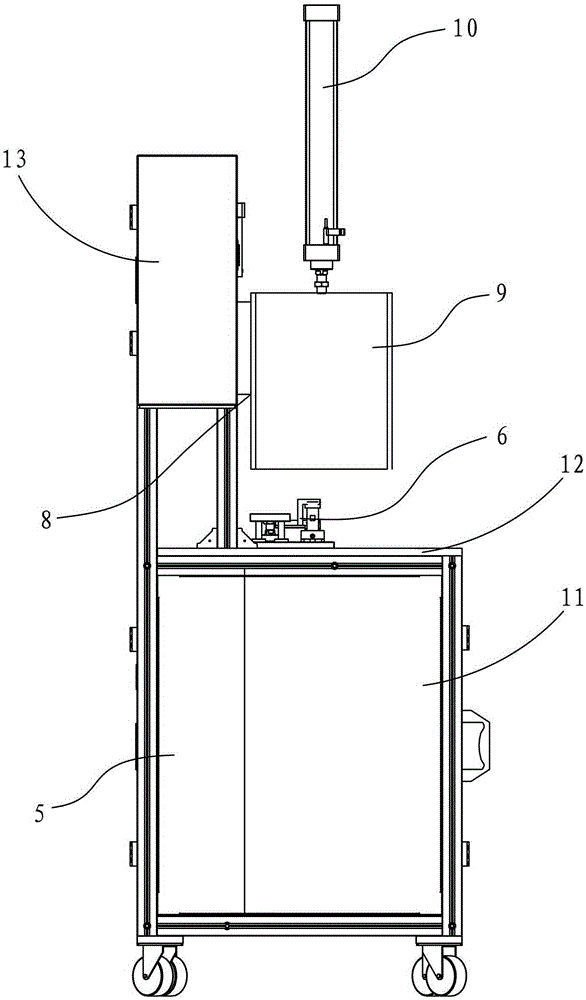

[0021] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0022] Before explaining the present invention, a supplementary explanation is made on the terms involved. "Product" refers to a product with a flow channel that has at least one water (air) inlet and one water (air) outlet, such as bathroom products such as showers and faucets, and pipeline products such as medical infusion tubes. "Vacuum pumping" refers to the formation of near-vacuum conditions, which can reach the vacuum conditions generally recognized in the industry, such as a vacuum degree of 0.1-0.5mbar (referring to the maximum negative pressure that the vacuum pump can pump out).

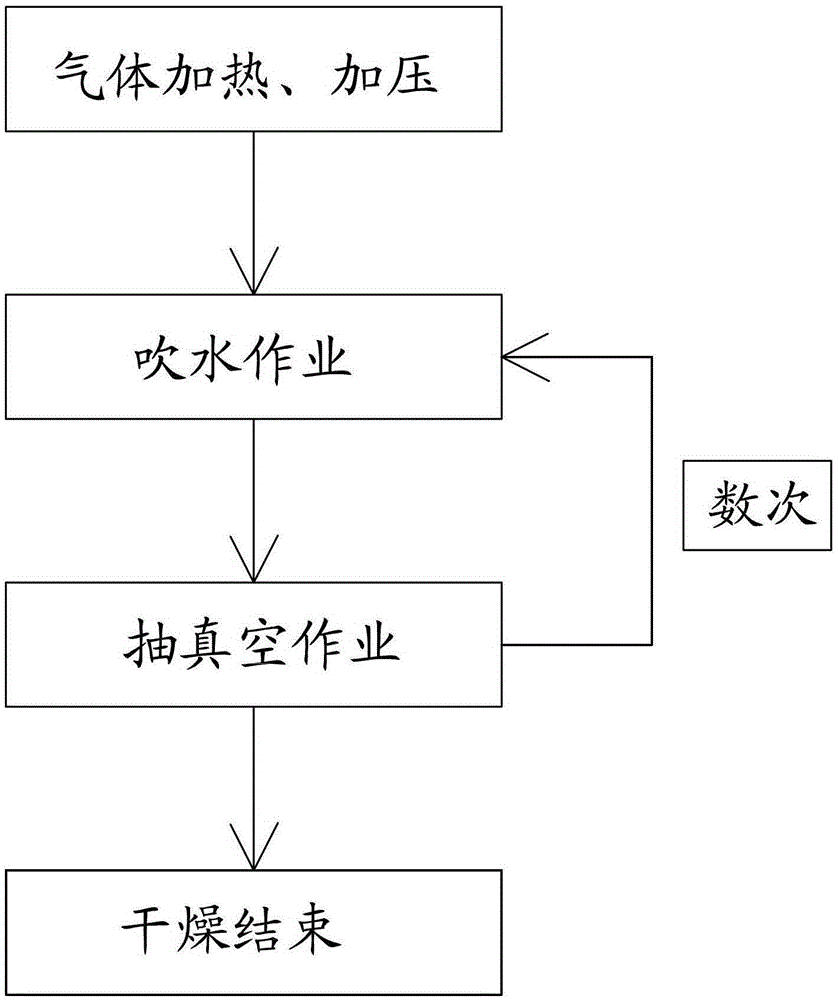

[0023] refer to figure 1 As shown, the dehydration and drying treatment of the present invention is: A). First pressurize and heat non-corrosive normal temperature (0-35°C) and normal pressure (0.1Mpa) gas (air is generally used), preferably, add Press to 0.3-0...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap