Mine underground filling system

A technology for mines and pipelines, applied in the field of underground filling systems in mines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

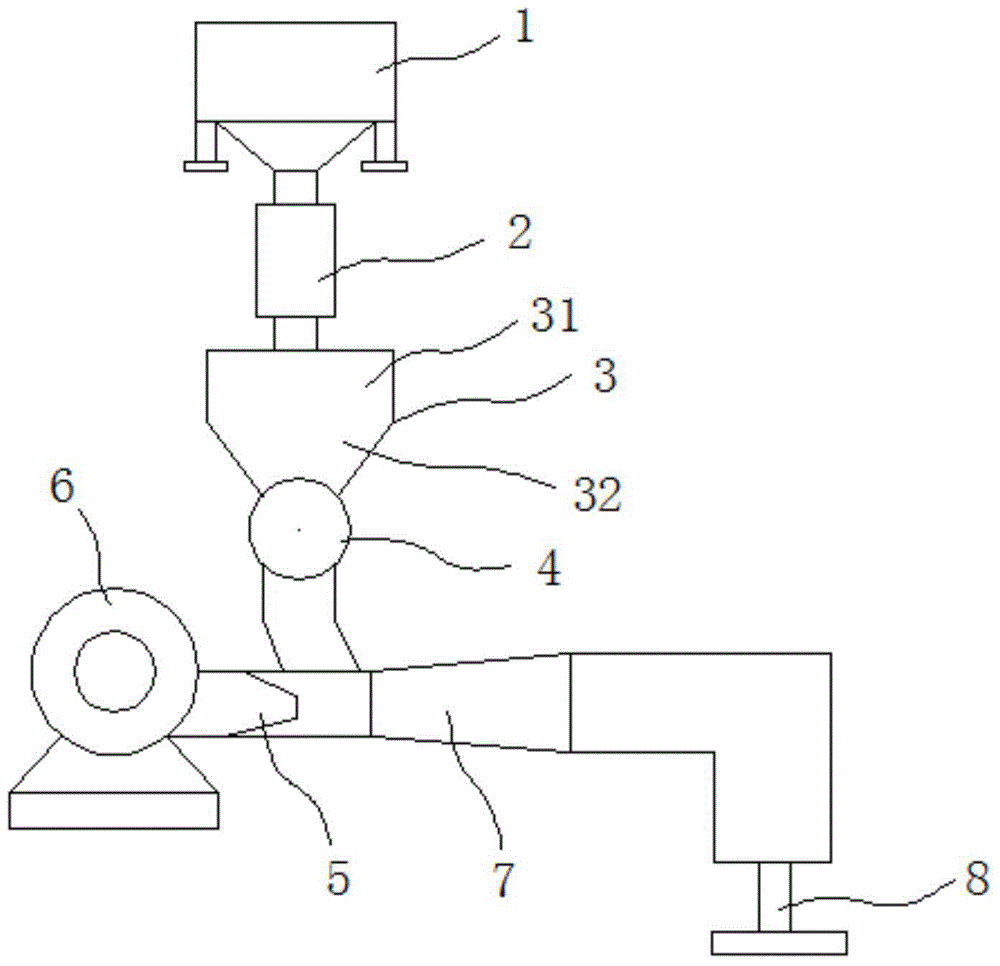

[0019] Such as figure 1 As shown, a mine underground filling system includes a filter 1, a dryer 2, a feed bin 3, a rotary feeder 4, an injector 5, a fan 6, a filling pipeline 7 and a rotary machine 8, and the filter The feed end of 1 is introduced into the tailings slurry through the pipeline, the discharge end of the filter 1 extends into the upper end of the dryer 2, and the lower end of the dryer 2 extends into the feed bin 3, so The lower end of the feed bin 3 communicates with the upper end of the rotary feeder 4, the lower end of the rotary feeder 4 extends into the filling pipeline 7, and the injector 5 is placed in the filling pipeline 7 One side, and the injection port of the injector 5 extends into the f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap