Tungsten-molybdenum wire cleaning machine

A cleaning machine, tungsten and molybdenum technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems such as the vibration resistance performance and life of bulbs that affect the performance of tungsten wire winding, cracks or burrs, and brittleness of tungsten and molybdenum processed materials, and achieve simplification. The effect of installing and debugging programs, reducing processing and production costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

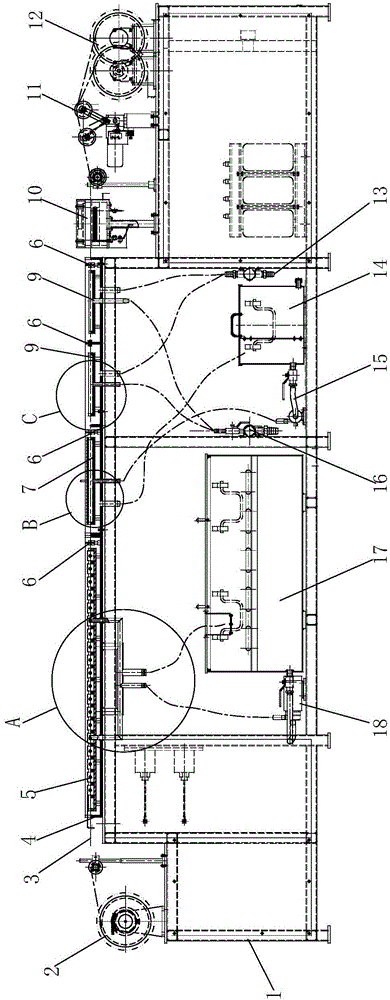

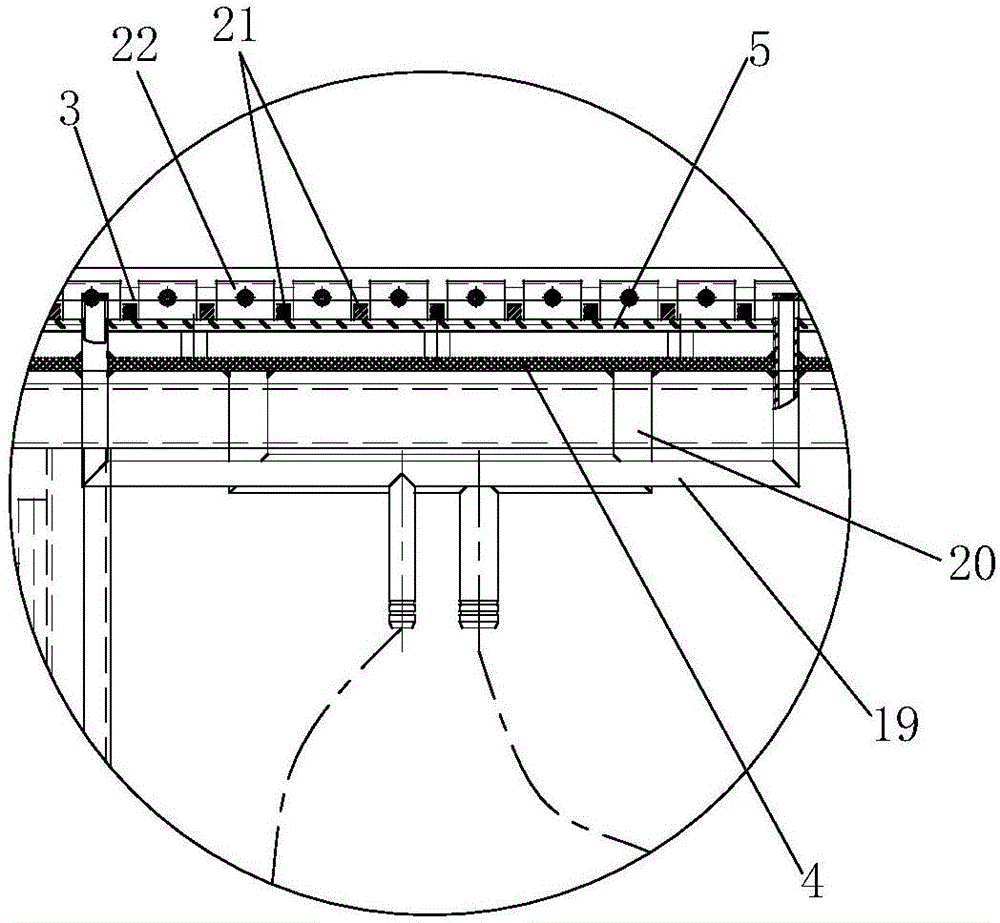

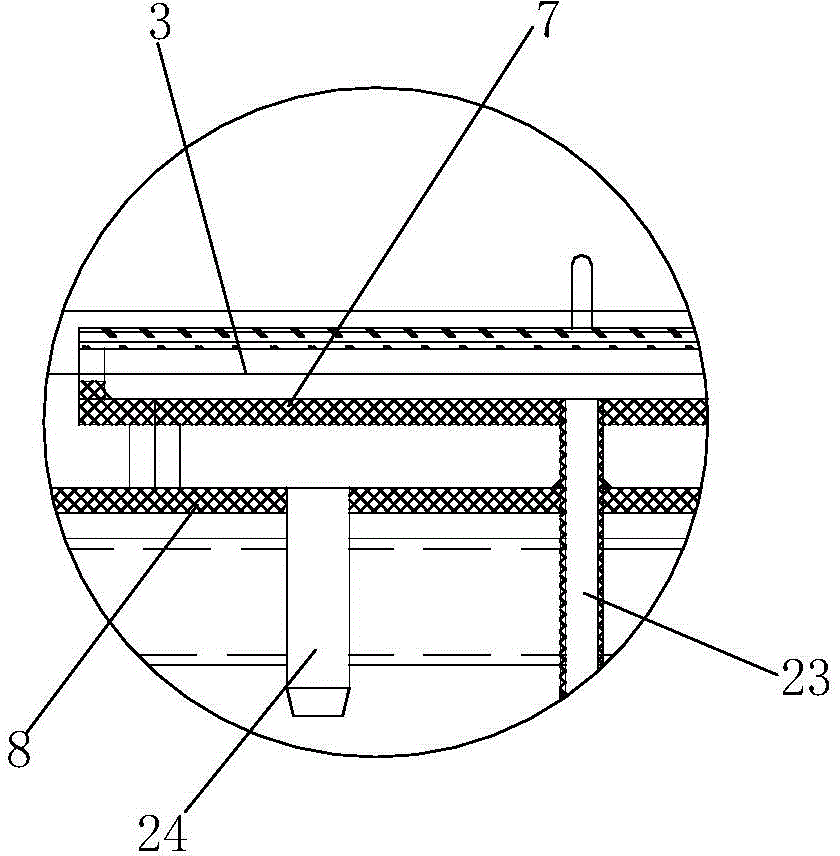

[0039] Such as figure 1 , figure 2 and Figure 6 A tungsten and molybdenum wire cleaning machine shown includes a frame 1, a pay-off mechanism 2 arranged on one side of the frame 1, and a take-up mechanism 12 arranged on the other side of the frame 1, on which the frame 1 and The electrolytic cell 5 between the pay-off mechanism 2 and the take-up mechanism 12, in the electrolytic cell 5 and along the length direction of the electrolytic cell 5, a plurality of partitions 21 are arranged, and two adjacent partitions 21 are arranged between There are two electrode plates 22 .

[0040] combine Figure 5 , during use, a pair of electrode plates 22 are simultaneously electrified positively or negatively, and the next pair of electrode plates 22 are simultaneously electrified negatively or positively. plate 22 contact, and through the electrode plate 22 immersed in the electrolytic solution, the electric charge of the opposite polarity to that on the electrode plate 22 will be i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap