Bolt torque detection device

A torque detection and bolt technology, applied in the field of bolt torque detection devices, can solve the problems of high labor intensity, low input-output ratio, large errors, etc., and achieve the effect of overcoming inaccurate loading, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

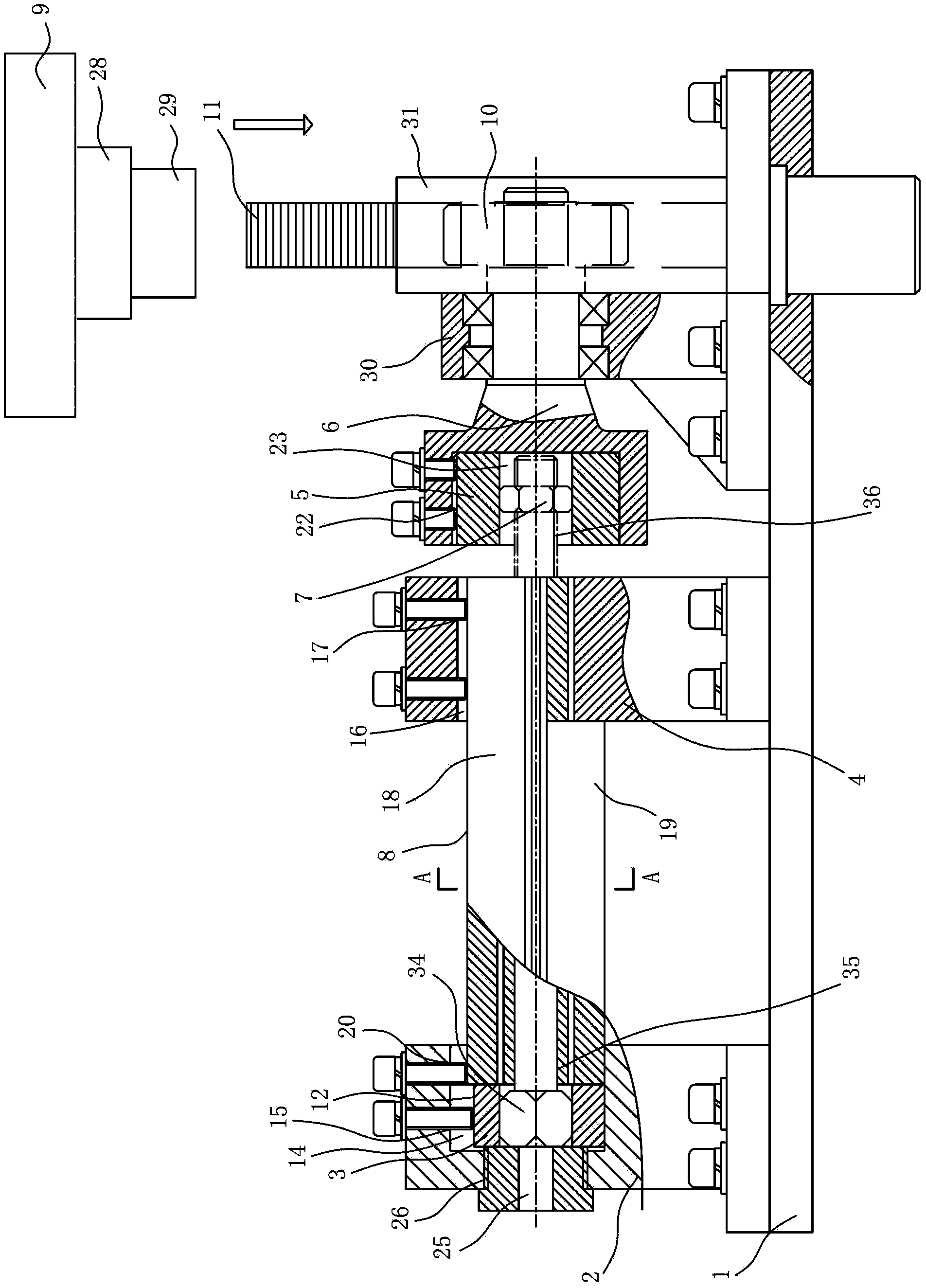

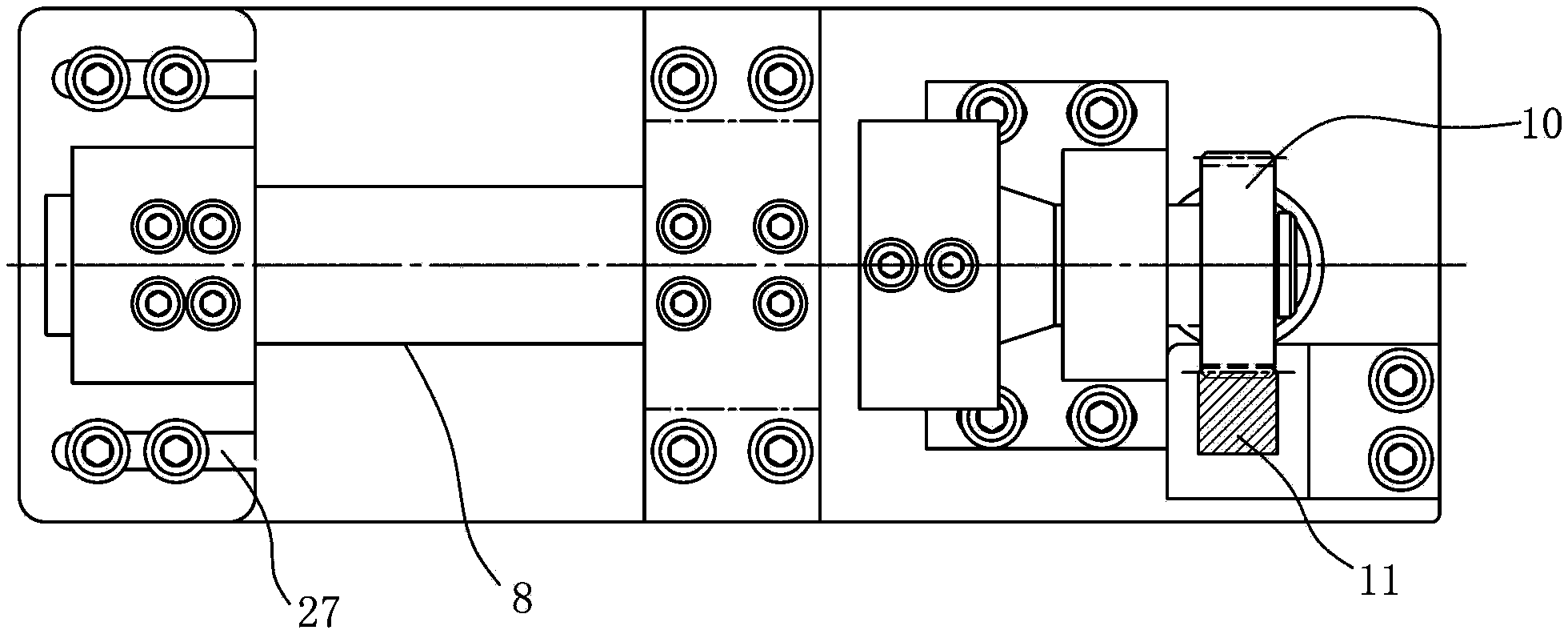

[0035] Embodiment one: see Figure 1-7 As shown, a bolt torque detection device includes a machine base 1 on which a head support seat 2, a gear seat 30 and a rack seat 31 are fixed, and the detection device also includes a head chuck 3 , nut chuck 5, rotating sleeve 6, nut 7, tensile testing machine 9, gear 10, rack 11 and back cap 25;

[0036] The rack 11 slides vertically up and down on the rack seat 31, the gear 10 is supported by the gear seat 30 and rotates around the horizontal line, the gear 10 is coaxially connected with the rotating sleeve 6, the gear 10 and the rack 11 mesh, and the tensile testing machine 9. Drive and connect the rack 11 to drive the rack 11 to slide, and drive the gear 10 and the rotating sleeve 6 to rotate;

[0037] The head support seat 2 is provided with a connected head support seat hole 14 and a head chuck pressing screw hole 15, the head chuck 3 is inserted into the head support seat hole 14, and the head clamp After the screw is assembled...

Embodiment 2

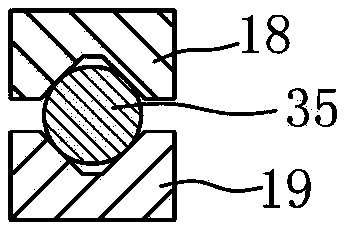

[0049] Embodiment two: see Figure 8As shown, a bolt torque detection device has the same basic structure as the first embodiment, and also includes a rod support seat 4 and a rod pressing block 8; Hole 32, the rotation sleeve through hole 32 is axially horizontal, the bolt thread section 36 in the corresponding nut chuck hole 23 of the hole, the bolt head 34 of the corresponding bolt of the described back cap hole 26 holes, and the back cap hole 26 size is larger than the bolt The size of the head 34; the horizontal distance between the rod support seat 4 and the nut chuck 5 is greater than the thickness of the nut 7, unscrew the screw in the head chuck pressing screw hole 15, and loosen the nut chuck pressing screw Screw in the hole 22, unscrew the screw in the screw hole 17 at the right end of the pressure block on the rod, unscrew the screw in the screw hole 20 at the left end of the pressure block on the rod, and use the push rod 33 to extend into the through hole 32 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com