Electric eddy transducer dynamic calibration device

An eddy current sensor and dynamic calibration technology, applied in the field of measurement and testing, can solve the problems of inaccurate correspondence between the eddy current sensor and the test platform, low calibration accuracy, etc., and achieve good neutrality, large contact area, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

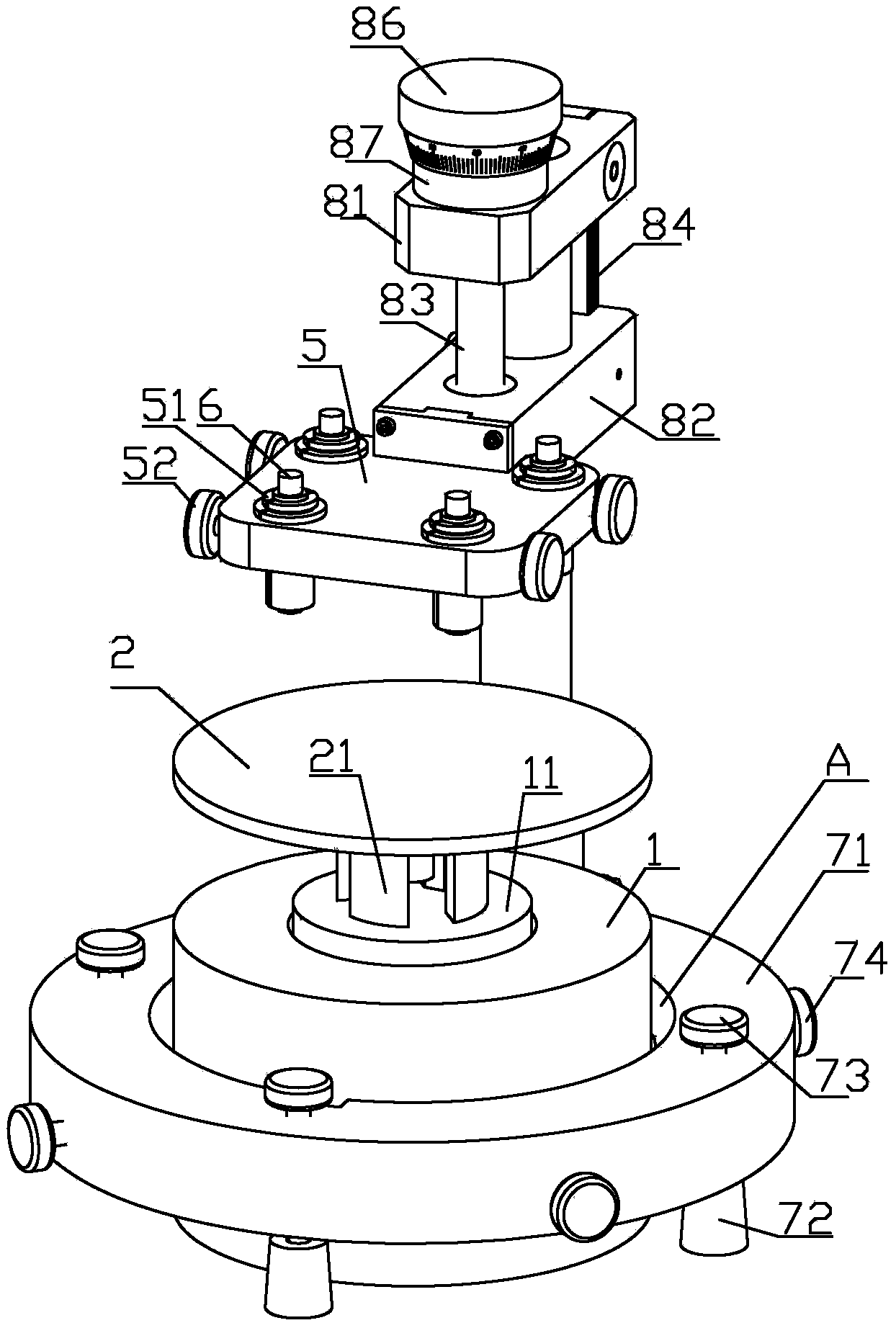

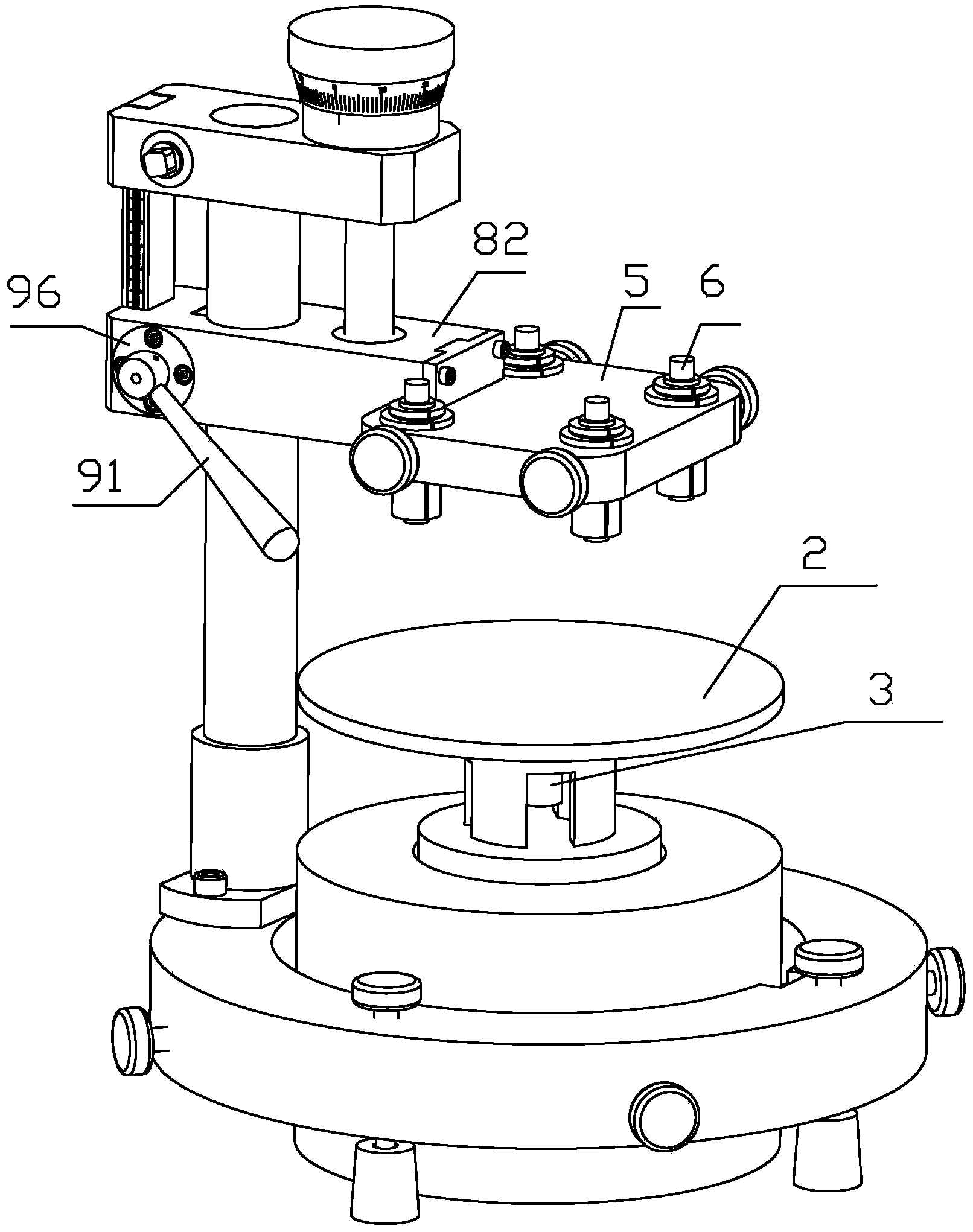

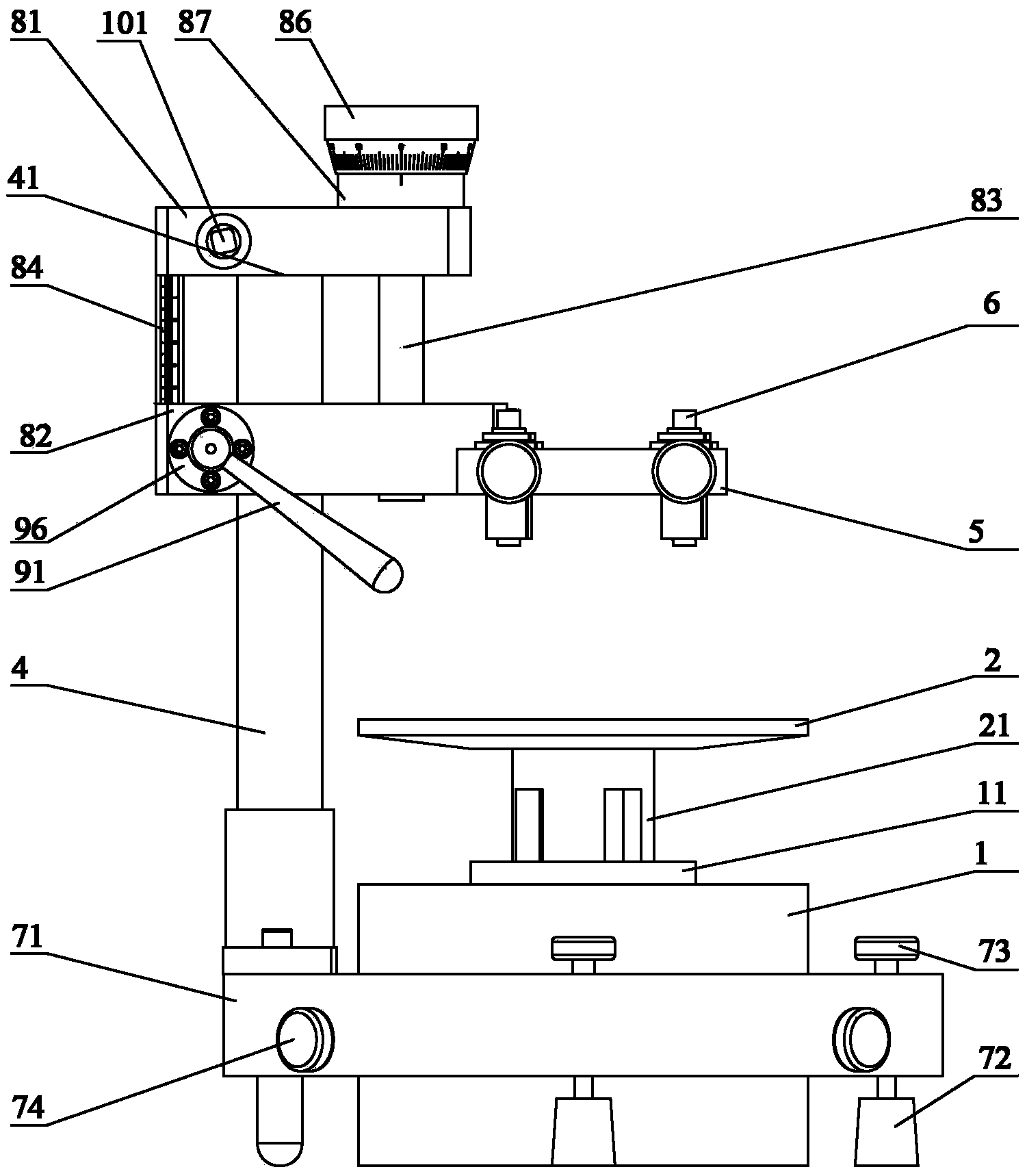

[0031] Such as Figure 1-3 As shown, the dynamic calibration device for the eddy current sensor includes a vibrating table 1, a base, an induction disc 2 fixed on the moving coil of the vibrating table 1, a standard acceleration sensor 3 fixedly connected to the induction disc 2, and an installation with an eddy current sensor An adjustment mechanism, and a support rod 4 connecting the base and installing the adjustment mechanism. The bottom of the support rod 4 is fixed on the base by screws.

[0032] The installation adjustment mechanism includes a mounting plate 5 for installing the eddy current sensor and a position adjustment mechanism that drives the mounting plate 5 to move up and down, and the mounting plate 5 is provided with a plurality of mounting holes for the eddy current sensor 6 , the mounting holes are evenly distributed, and there are positioning parts for fixing the eddy current sensors 6 in the mounting holes. The positioning member includes a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com