Method for measuring distribution of intensity of light spots of reflecting type concentrating photovoltaic condenser

A concentrating photovoltaic and intensity distribution technology, which is applied in the direction of testing optical properties, can solve problems such as high energy flow density, and achieve the effect of simple operation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

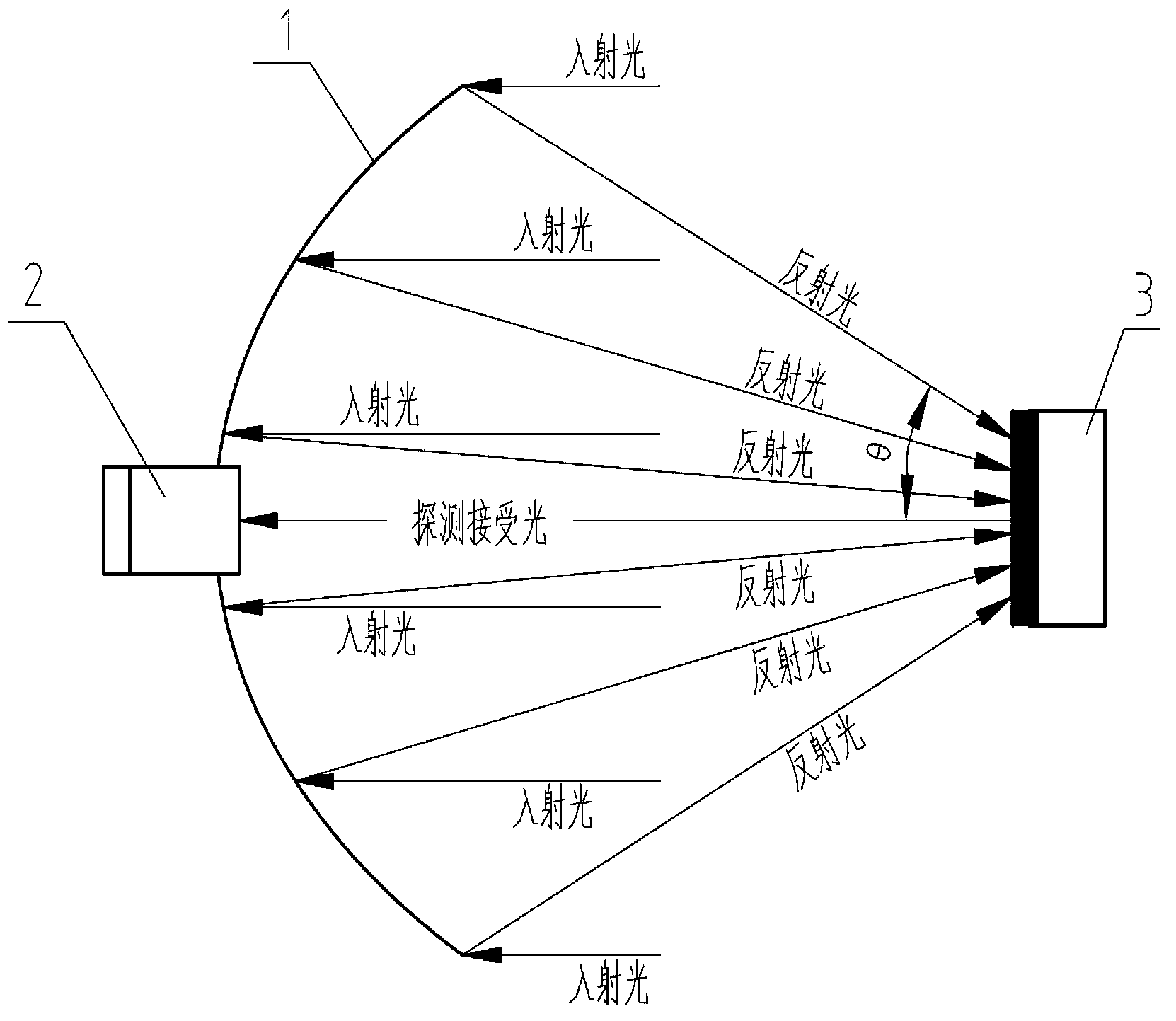

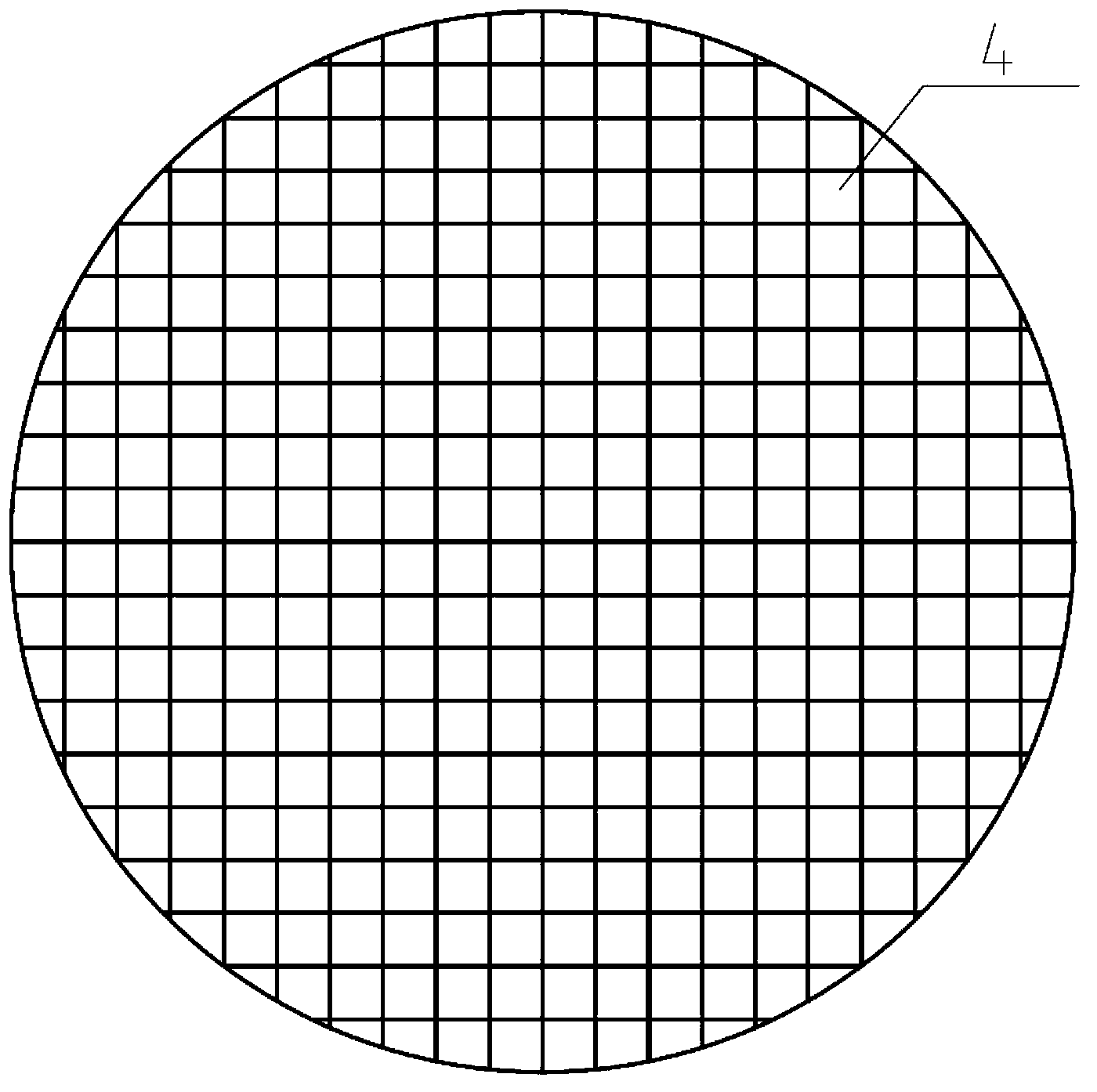

[0027] Example: see figure 1 2. A method for measuring the intensity distribution of light spot of a reflective concentrating photovoltaic concentrator, characterized by comprising the following steps: (1) dividing the rotating parabolic reflective surface into reflective elements of a certain area; (2) using a detector to record the solar radiation After each reflection element is reflected, the image formed on the reflection plate is a pixel; (3) each pixel is superimposed to obtain the light intensity distribution on the reflection plate of the reflective concentrator.

[0028] The area of the reflecting element needs to be smaller than the area of the reflecting plate.

[0029] The detector is fixed at the lowest point of the rotating parabolic reflecting surface when recording the picture elements on the reflector after the sunlight is reflected by each reflecting element. The detector is fixed to the vertex of the rotating paraboloid, that is, the lowest point, and ...

experiment example

[0038] Experimental example: see figure 1 , a method for measuring the spot intensity distribution of a reflective concentrating photovoltaic concentrator,

[0039] The opening section of the condenser of the rotating parabolic mirror 1 is a circle with a diameter of 3.2 m.

[0040] The detector 2 is a commercially available digital camera. It is installed at the lowest point of the rotating parabolic reflector, that is, at the apex of the parabola of the largest cross-section.

[0041] The reflector 3 is an ordinary plane reflector, the size of the mirror surface is 200mm×200mm, and the reflectivity of the mirror surface is 93%.

[0042] The reflection plate 3 is 2.77 m away from the opening section of the rotating parabolic mirror 1 .

[0043] The measurement of the light intensity distribution on the reflector 3 after the sunlight is reflected by the rotating parabolic reflector 1 is carried out according to the following steps:

[0044] (1) Divide the rotating paraboli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com