Testing jig for testing mobile phone PCB pin point conduction

A technology for testing PCB boards and mobile phones. It is applied in electronic circuit testing, parts of electrical measuring instruments, and measuring electricity. It can solve problems such as inconvenient use, crushing PCB boards, and testing equipment without lighting functions. Convenience and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

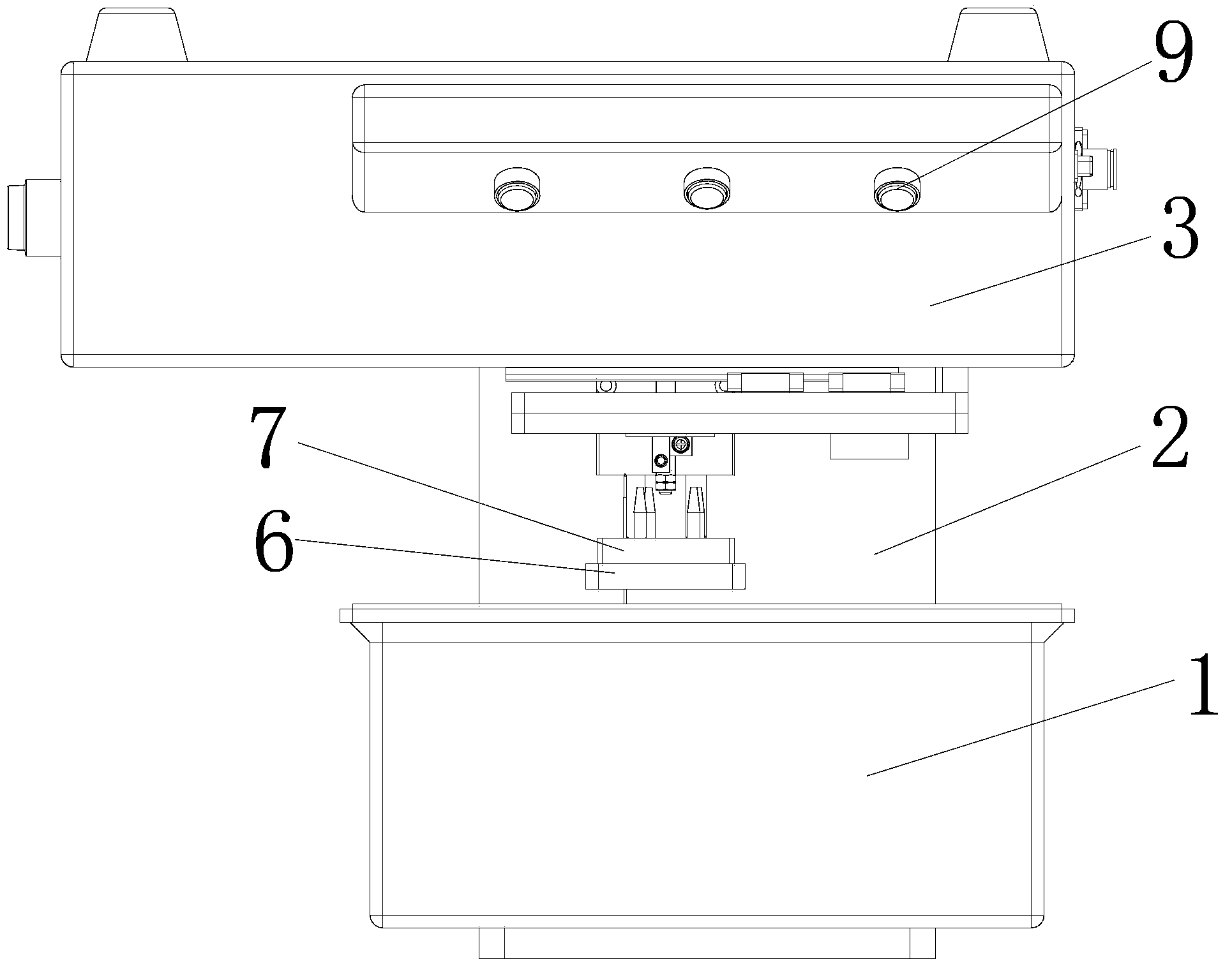

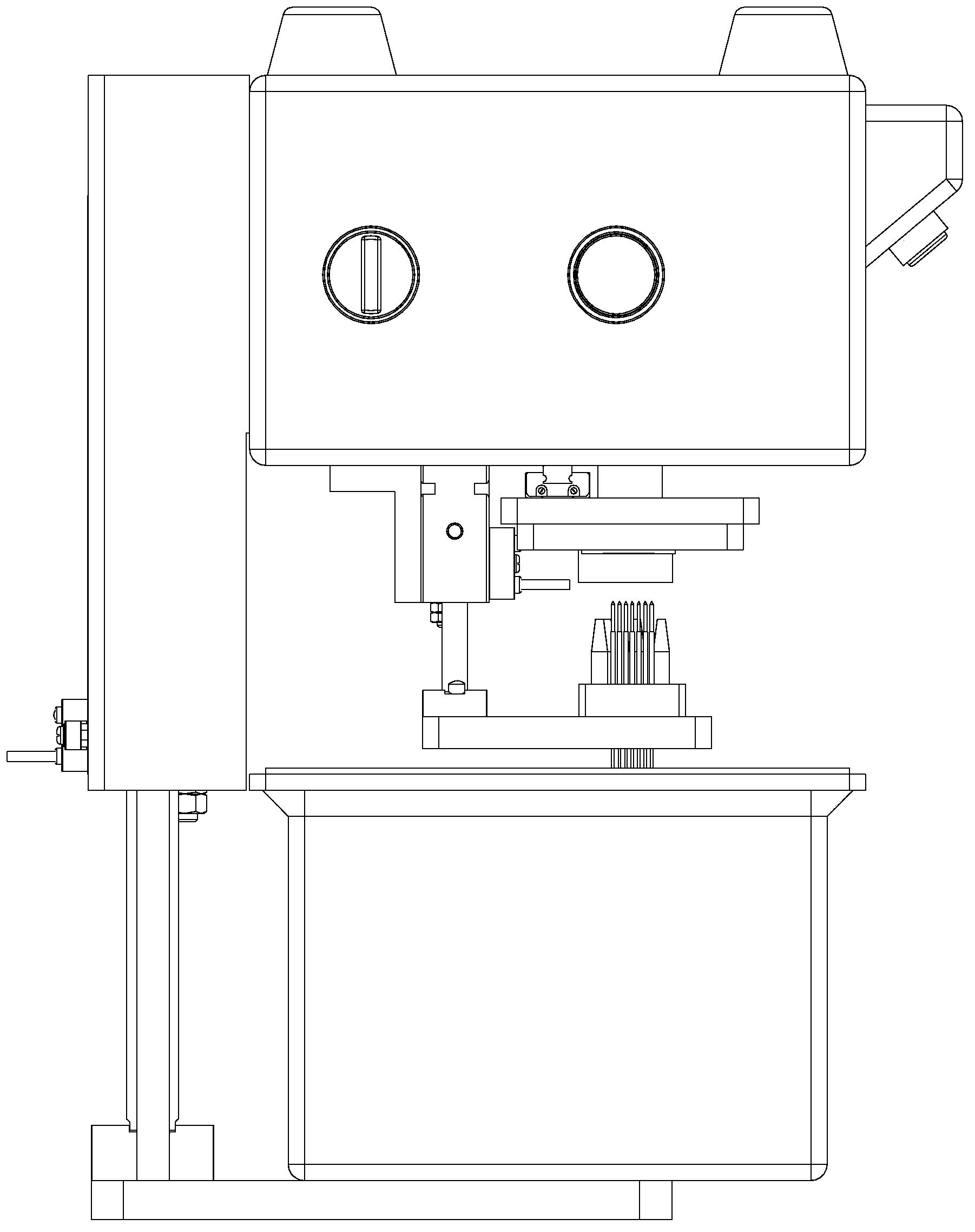

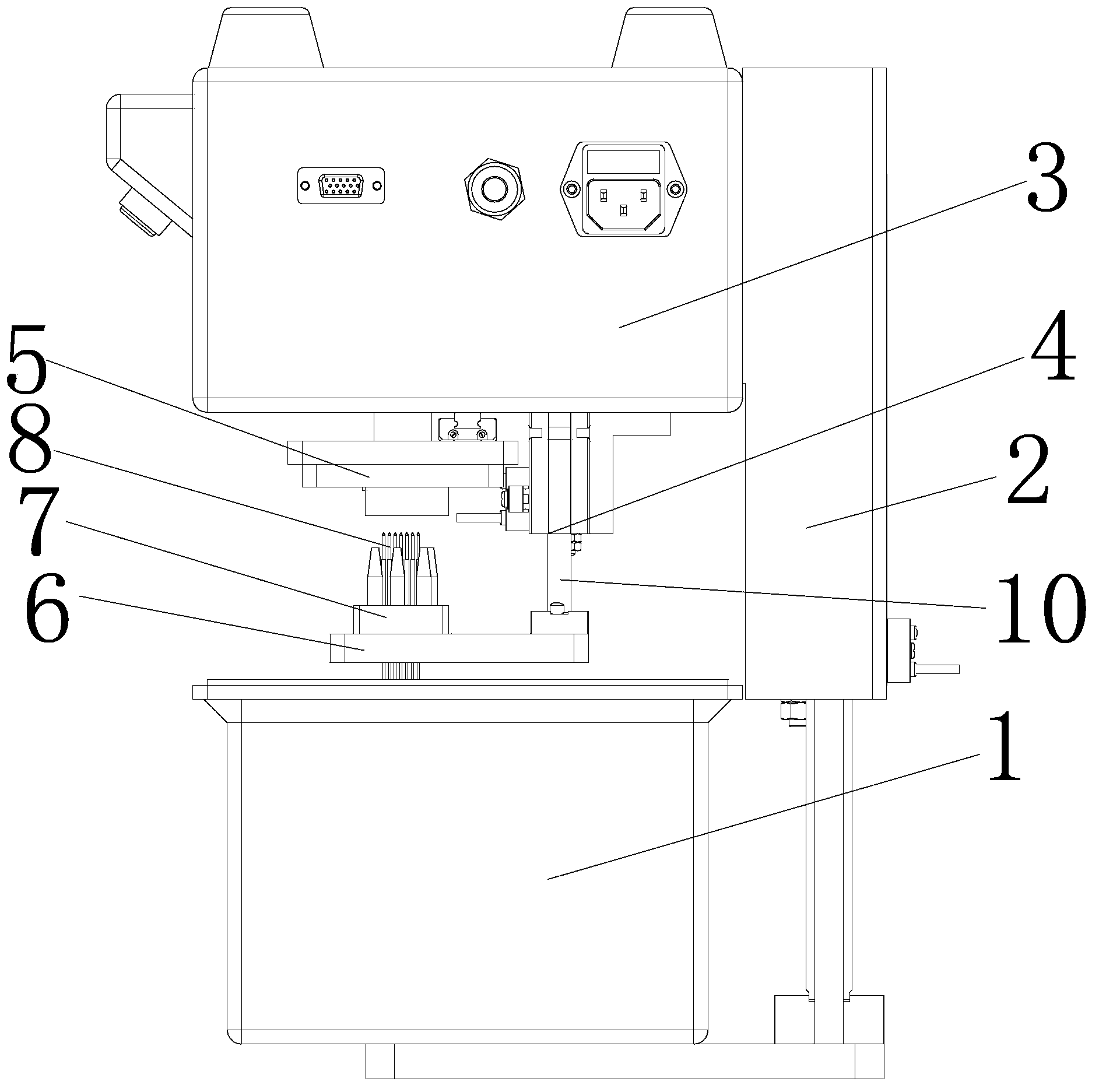

[0014] Such as Figure 1-3 As shown, a test fixture for testing the pin-point conduction of a mobile phone PCB board includes a test bench 1, a support plate 2, a top seat 3, a cylinder 4, a positioning carrier plate 5, a moving plate 6, a pin insertion plate 7 and The probe 8 is provided with a support plate 2 on the rear side of the test platform 1, and a top seat 3 located above the test platform 1 is connected to the front end of the support plate 2, and a positioning carrier plate for placing a PCB board is provided at the bottom of the front end of the top seat 3 5. A cylinder 4 is arranged at the bottom of the rear end of the top seat 3, and the cylinder rod 10 of the cylinder 4 is connected to the moving plate 6 arranged horizontally, and a pin plate 7 is arranged on the top of the moving plate 6. Set in the pin board 7 and point to the PCB board. A row of la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com