Deep trench filling structure and fabrication method thereof

A manufacturing method and a technology of deep grooves, which are applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as output signal distortion, and achieve the effect of improving radio frequency characteristics and reducing distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

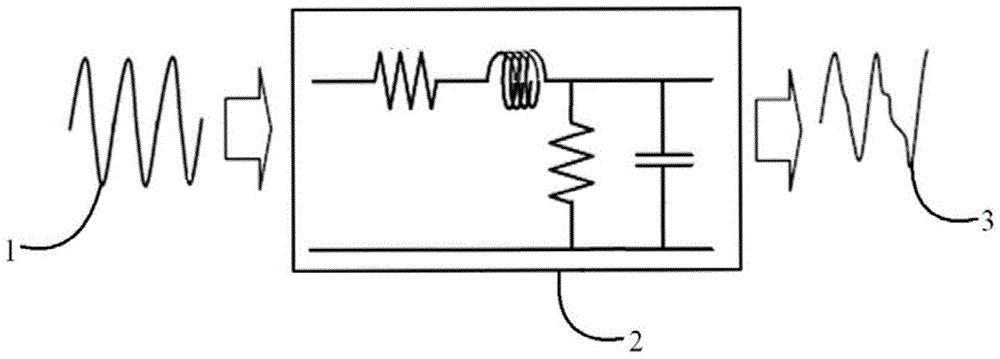

[0033] Existing integrated circuit components using silicon-on-insulator are prone to the problem of waveform distortion of the output radio frequency signal when a relatively large amplitude radio frequency signal is passed through.

[0034] By analyzing the equivalent model of the RF transmission line with SOI as the substrate, it is found that: due to the large amplitude of the radio frequency signal, it is easy to cause depletion or even inversion of the substrate below the SOI buried oxide layer. This process is accompanied by changes in free carriers, which is equivalent to The capacitance in the equivalent model changes. Therefore, the radio frequency signal passing through the transmission line is interfered, and a distorted output signal is easily generated.

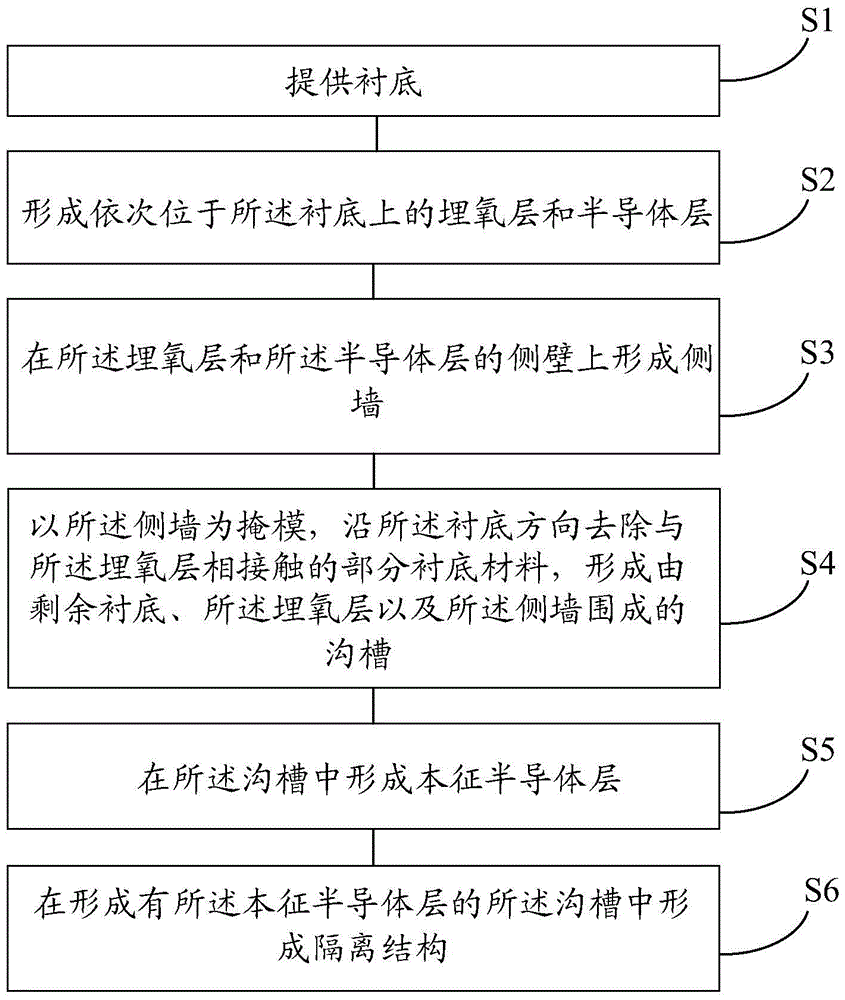

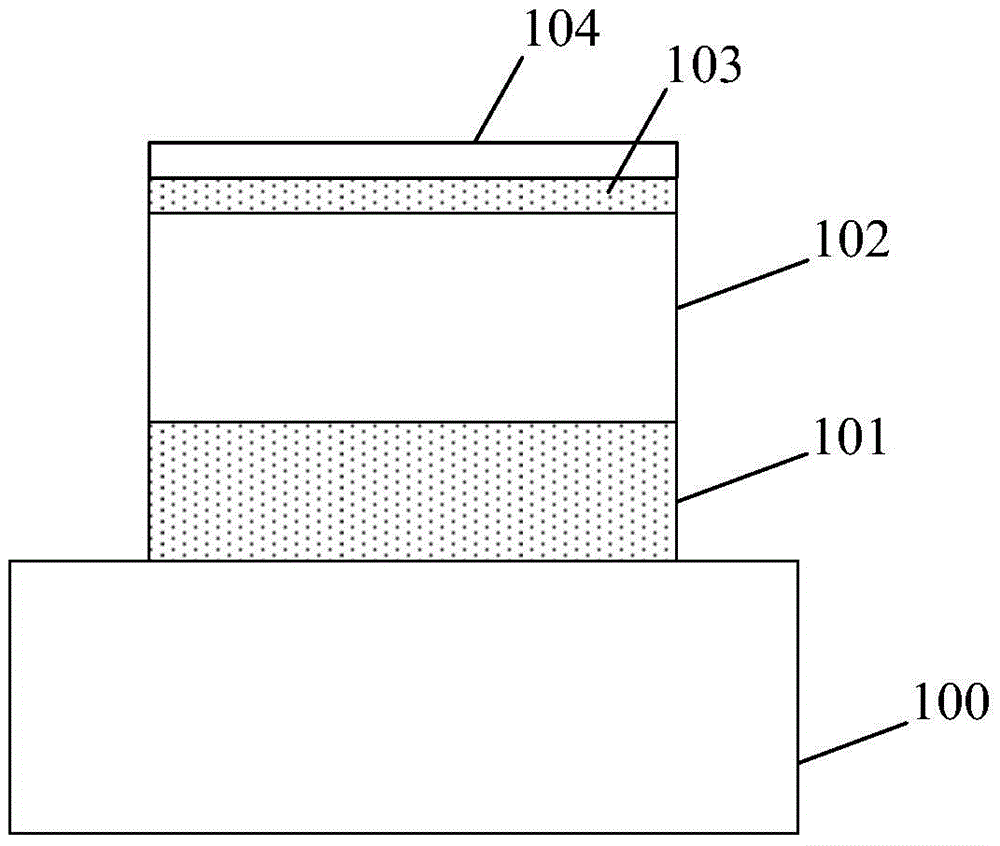

[0035] In order to solve the above technical problems, the present invention provides a method for manufacturing a deep trench filling structure. refer to figure 2 , showing a method for fabricating a deep tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap