Novel cavel combination gap

A combination of gap and claw technology, applied in the field of electric power, can solve the problems of fixed electrical characteristics, less research, complex discharge rules, etc., and achieve the effects of strong ablation resistance, stable discharge voltage, and rapid arc extinguishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

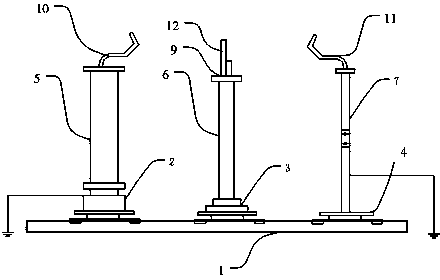

[0020] Before describing the novel croissant combination gap of the present invention, at first the parts indicated by the label in the figure are described as follows:

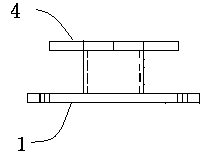

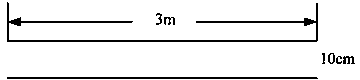

[0021] 1 indicates the I-beam base; 2.3.4 respectively indicates the first base slider, the second base slider, and the third base slider; 5.6 indicates the first post insulator and the second post insulator respectively; 7 indicates the adjustable post; 8 Represents a height-adjustable support; 9 represents a support for fixing the metal plate; 10 and 11 represent the first claw electrode and the second claw electrode respectively; 12 represents the metal plate.

[0022] see figure 1 , is a structural schematic diagram of Embodiment 1 of the novel horn combination gap of the present invention.

[0023] The novel croissant combination gap in Embodiment 1 of the present invention includes: I-beam base 1, first base slider 2, second base slider 3, third base slider 4, croissor gap combination, adjustable pilla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com