Permanent-magnet brushless direct-current motor stator with novel parallel winding wiring

A brushless motor, permanent magnet DC technology, applied in the shape/style/structure of winding conductors, static parts of magnetic circuit, shape/style/structure of magnetic circuit, etc. Slow down and other problems to achieve the effect of reducing magnetic energy loss, avoiding excessive current, and reducing the possibility of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with specific embodiment, see figure 1 -2:

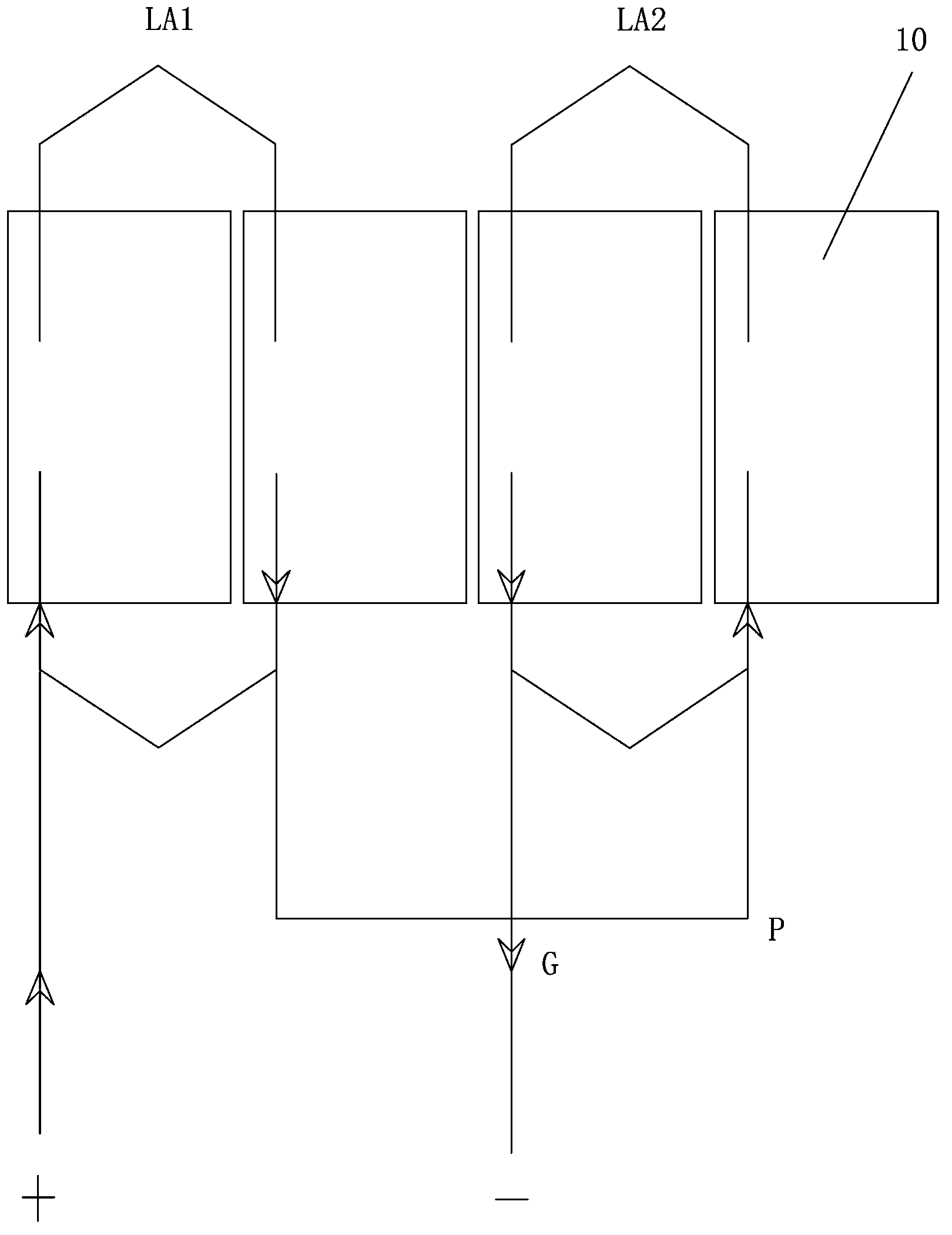

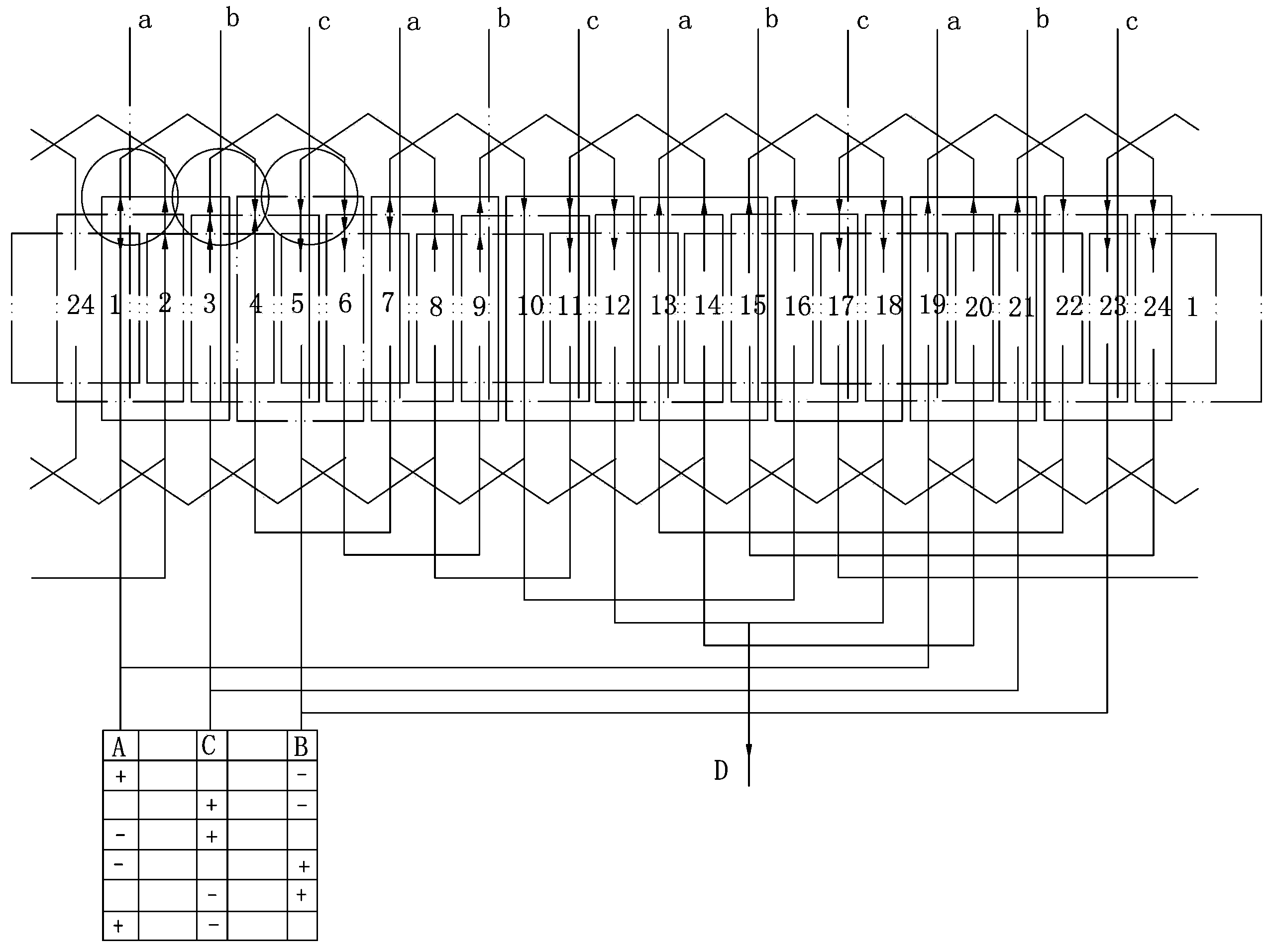

[0015] A permanent magnet brushless DC motor stator adopting new parallel winding wiring, including a stator core 10 and a stator winding, each phase winding is composed of two sections of winding, the two sections of winding are wound along the stator slots on the stator core 10, and the two The segment windings are connected in parallel to form the phase line common end and the phase line input end respectively.

[0016] The parallel connection of the above two sections of windings is: the first section of winding and the second section of winding have the same coil winding order, and the two sections of windings are respectively distributed in the stator slot shape with one section of clockwise embedded wires and the other section of counterclockwise embedded wires, clockwise embedded wires The tail of the counterclockwise embedding wire is connected to the head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com