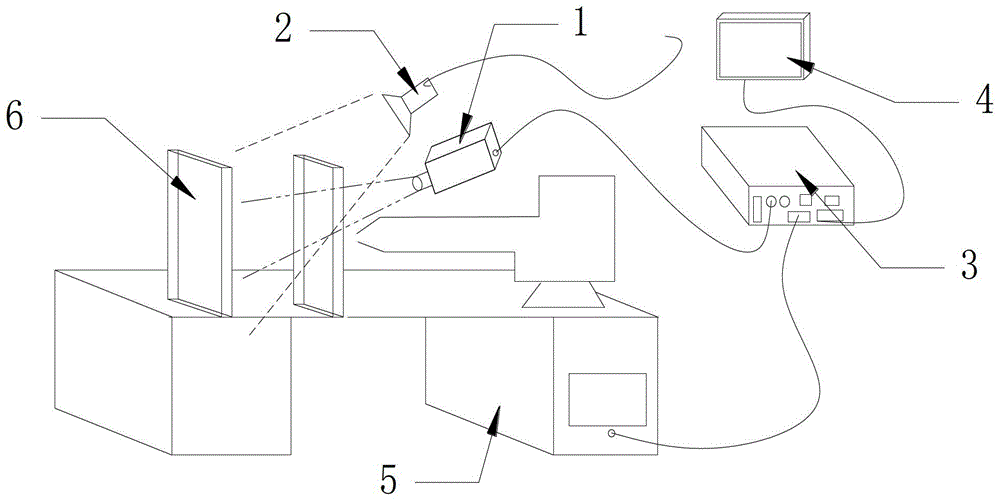

Die-casting mold monitoring and protection system and method

A die-casting mold and protection system technology, applied in the field of monitoring equipment, can solve the problems of flying materials hurting people, mold crushing, etc., and achieve the effect of improving service life and reducing safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0024] Embodiment 2: the system of the present invention may also include an input device and a prompting device 4; the input device is used to set a comparison area, for example, the operator sets coordinates (5,5) and (5,4) as a comparison area through the input device ; The processor judges whether the gray value difference in the corresponding position of the comparison area between the standard state gray pattern before mold closing and the standard state gray pattern after mold opening is greater than a preset threshold, for example, the same with a preset threshold of 20 For example, the gray value of the point with coordinates (5,5) in the standard state gray pattern after mold opening is 23, and the gray value of the point with coordinates (5,4) is 26, while the standard state before mold closing In the grayscale pattern, the grayscale value of (5,5) is 40, and the grayscale value of (5,4) is 41, then compare whether 17 is greater than 20, and whether 15 is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com