Tea-frying production line

A production line and tea-frying technology, applied in the field of tea-making tools, can solve the problems of low degree of mechanization, disadvantage, and low precision, and achieve the effect of improving the efficiency of tea-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

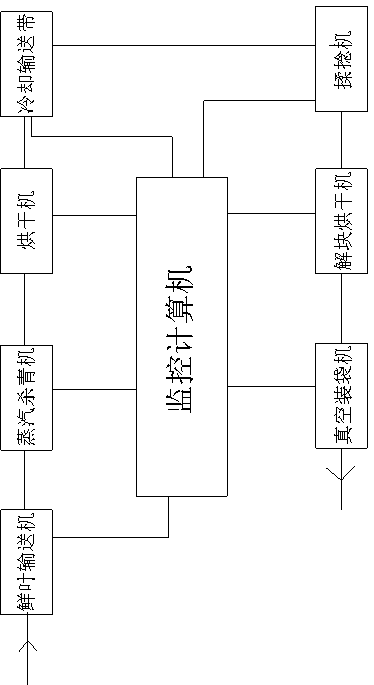

[0011] according to figure 1 As shown, the fried tea production line in the present invention includes a fresh leaf conveyor, a steam cleaning machine, a dryer, a cooling conveyor belt, a twisting machine, a vibrating deblocking dryer and a vacuum bagging machine arranged in sequence.

[0012] Wherein, the steam pipeline of the steam greening machine is provided with a steam pressure solenoid valve, and electric heating tubes are arranged in the dryer and the vibrating deblocking dryer, and the fresh leaf conveyor, the cooling conveyor belt, the kneading machine and the vibrating The deblocking dryer is equipped with a driving motor.

[0013] It also includes a monitoring and control computer, the control end of the monitoring and control computer is respectively connected with the motor of the fresh leaf conveyor, the steam pressure solenoid valve, the electric heating pipe in the dryer, the motor of the cooling conveyor belt, the motor in the kneading machine, The motor in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com