Hot-wind and steam combined de-enzyme machine

A technology of greening machine and steam, applied in the direction of tea processing before extraction, can solve the problems of low degree of mechanization, improve efficiency and low precision, and achieve the effect of avoiding excessive loss of tea moisture and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

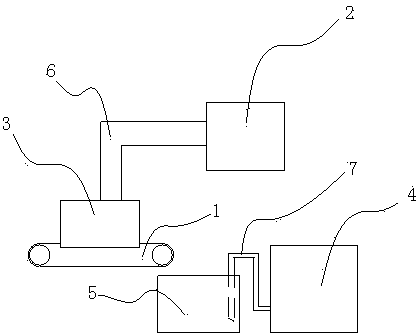

[0011] according to figure 1 As shown, the hot-air-steam combined de-greening machine in the present invention comprises a tea conveyor belt 1, a pressure steam boiler 2, a steam de-greening chamber 3, a hot-air generating device 4 and a cylinder type de-greening pot 5.

[0012] The steam cleaning chamber 3 surrounds a section of the tea conveyor belt 1, the tea conveyor belt 1 passes through the inside of the steam cleaning chamber 3, and the cylinder type cleaning pot 5 is arranged on the side of the tea conveyor belt 1. Below the conveying end, a steam pipe 6 is connected between the pressure steam boiler 2 and the steam cleaning chamber 3, and an air supply pipe 7 is connected to the air outlet of the hot air generating device 4, and the end of the air supply pipe is provided with Have to extend in the described cylinder type fixing pot 5.

[0013] The steam cleaning chamber 3 has a steam spray pipe connected to the steam pipeline 6, the steam spray pipe is made of a plur...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap