Sweet potato powder cooling device

A cooling device and technology of sweet potato flour, applied in the field of food processing, can solve the problems of increasing the drying time and reducing the processing efficiency of vermicelli, and achieve the effects of shortening the drying time, improving the cooling effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

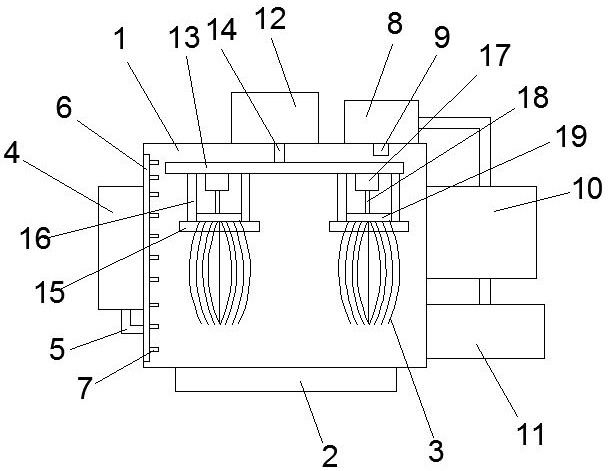

[0020] A sweet potato flour cooling device, comprising a casing 1 and a discharge port 2 located at the bottom of the casing 1, the casing 1 is provided with a rotating mechanism for hanging and driving the sweet potato flour 3 to rotate, and the front is provided with a rotating The door, the outer wall of the box 1 is equipped with a cooling fan 4, the bottom of the cooling fan 4 is connected with an air supply pipe 5, and one end of the air supply pipe 5 extends into the box 1 and is connected with a main pipe 6, The main pipe 6 is installed on the inner wall of the box 1, and a plurality of branch pipes 7 are arranged on it.

[0021] The present invention is by being provided with air cooler 4, air supply pipe 5, main pipe 6 and branch pipe 7, and the cold wind prepared by air cooler 4 is sent in the box body 1 through air supply pipe 5, main pipe 6 and branch pipe 7 successively, applies cold wind to The sweet potato flour 3 in the box 1 is cooled, which avoids the phenom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com