Mechanical automatic intravenous medicine mixing device

An intravenous drug, automatic technology, applied in the directions of drug packaging, packaging, packaged food, etc., can solve problems such as environmental pollution of intravenous drug preparation, and achieve the effect of reducing the probability of drug compatibility errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below with reference to the drawings.

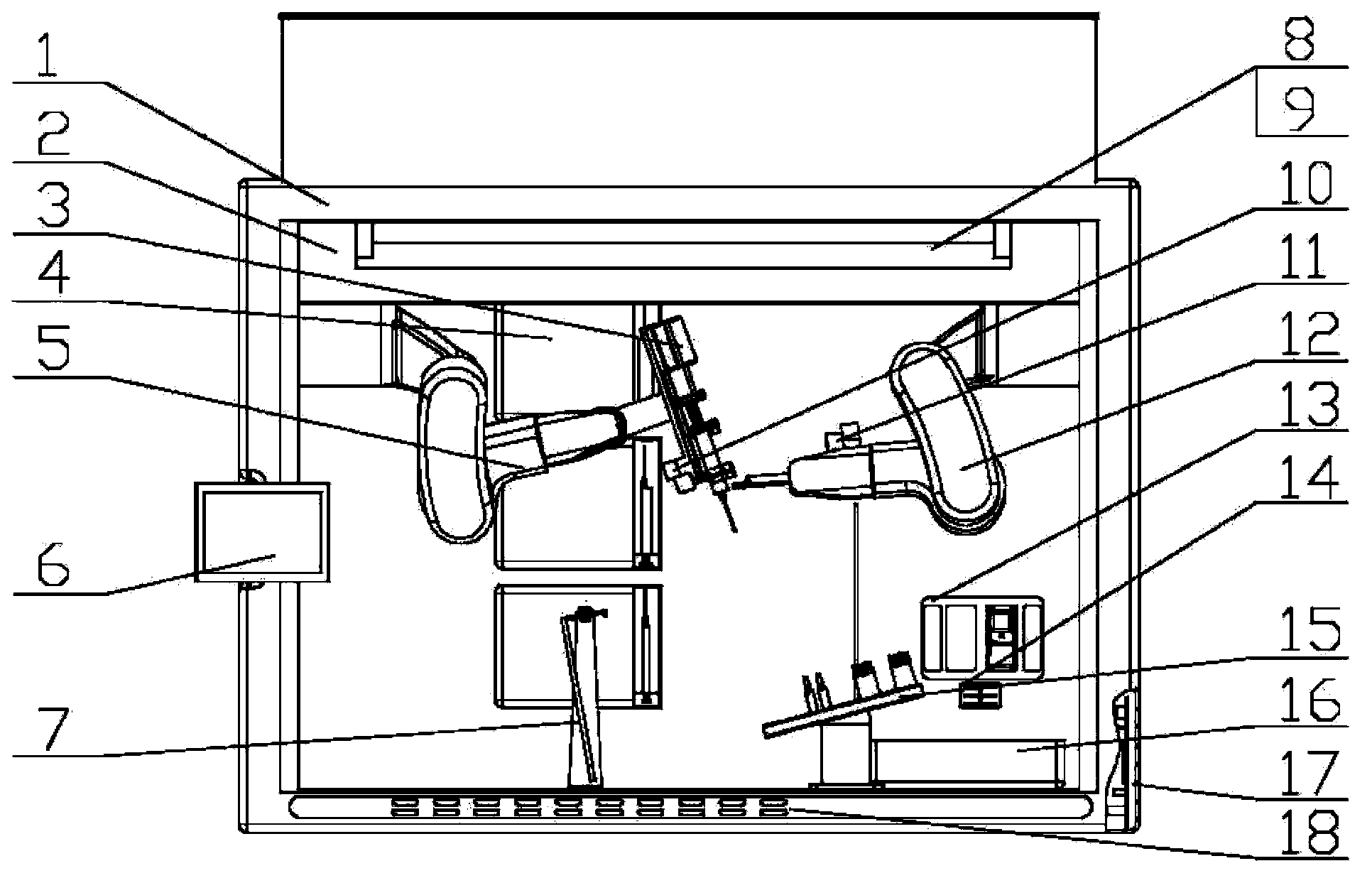

[0033] Such as Figure 1~Figure 8 As shown, this programmable, controllable and automatic configuration of intravenous drugs includes a sensor unit and a signal processing control circuit, and also includes.

[0034] The glass lift window 2 can be moved up and down by a motor drive.

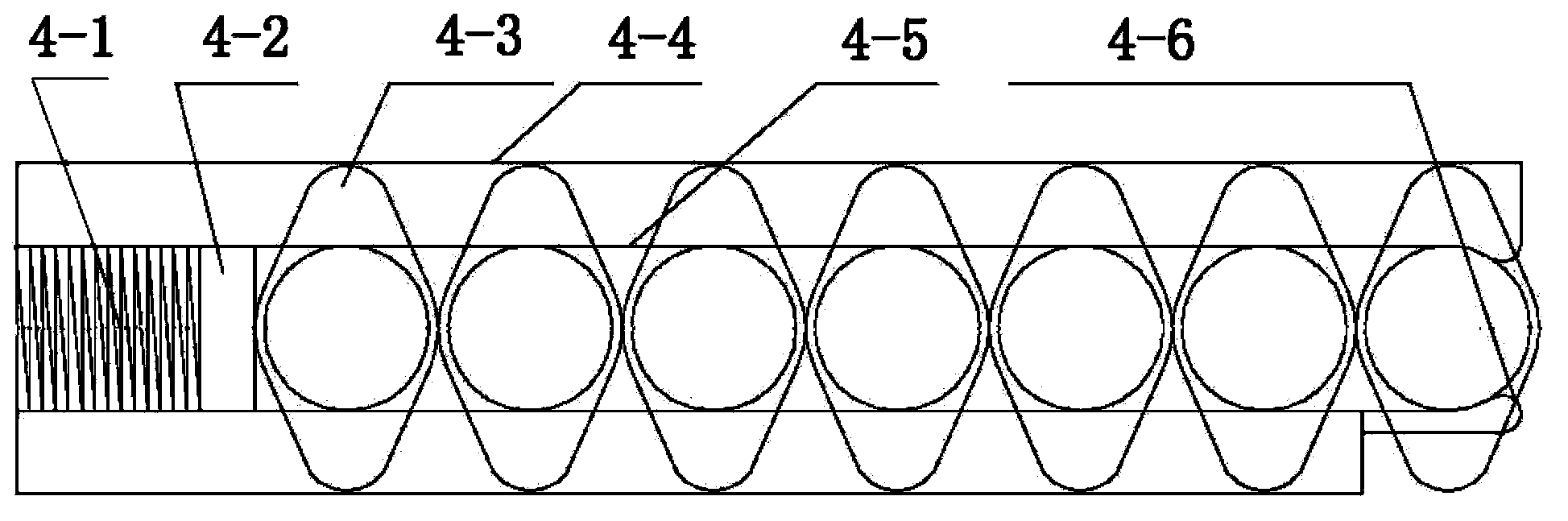

[0035] The syringe storage box 4 is used to store the syringe, and the syringe is ejected by the cooperation of the spring and the circlip.

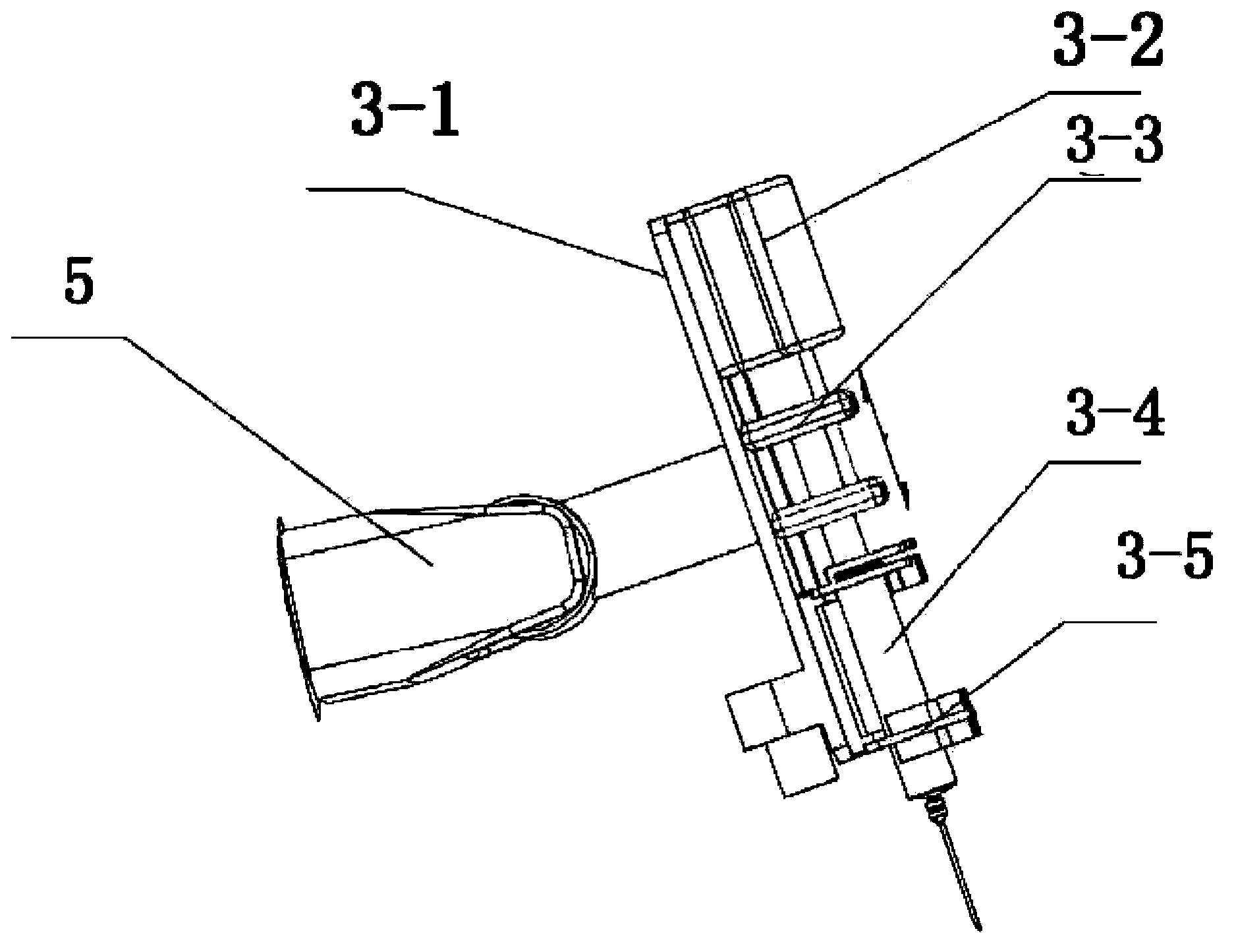

[0036] The dispensing manipulator 5 completes rotation and precise position movement through the program and the servo motor inside the manipulator, and cooperates with the feedback signal of the first sensor 10, so that the front robot finger can accurately grasp the syringe, through a push-pull device composed of a motor and a transmission mechanism 3Complete the push and pull operation of the syringe; include the touch screen 6, and operate the moving parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com