Locating pin clamp for welding, and operating method thereof

A positioning pin and fixture technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low positioning accuracy, positioning operation without positioning pins, time-consuming and labor-intensive, etc., to achieve outstanding substantive features, vertical The effect of high precision and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

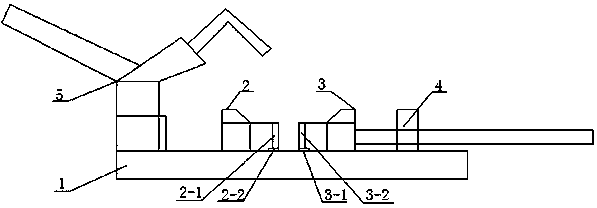

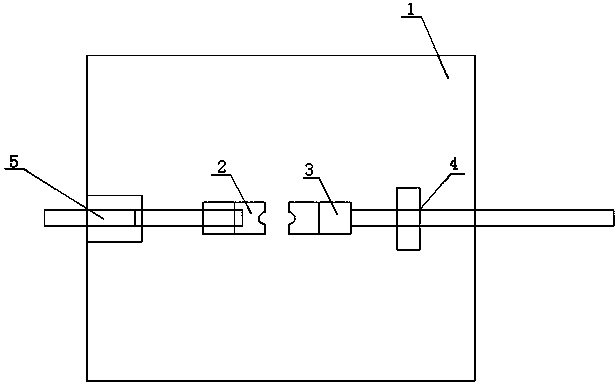

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0024] As can be seen from the accompanying drawings, the positioning pin clamp for welding of the present invention includes a base 1 on which a product clamp 5, a stop block 2, a movable block 3, and a clamp 4 are sequentially installed. The product clamp 5 and the limiting block 2 are fixed on the base 1 , the movable block 3 is slidably installed on the base 1 , and one end of the movable block 3 is connected with the clamp 4 .

[0025] The further improvement of the present invention is that: the end face of one end of the limiting block 2 is provided with concentric arc-shaped grooves I2-1 and arc-shaped grooves II2-2, and the vertical height of the arc-shaped groove I2-1 is greater than that of the arc. The vertical height of the arc-shaped groove II 2-2 is less than the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com