Method and device for filling containers with liquid material

A liquid filling and material technology, which is applied in the field of beverage container filling equipment, can solve the problems of low energy efficiency and infrequent use, and achieve the effect of reducing temperature input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments will be described below with reference to the accompanying drawings. Identical, similar or identically acting components are identified here with the same reference numerals, and a repeated description of these components is sometimes omitted in the following description to avoid redundancy.

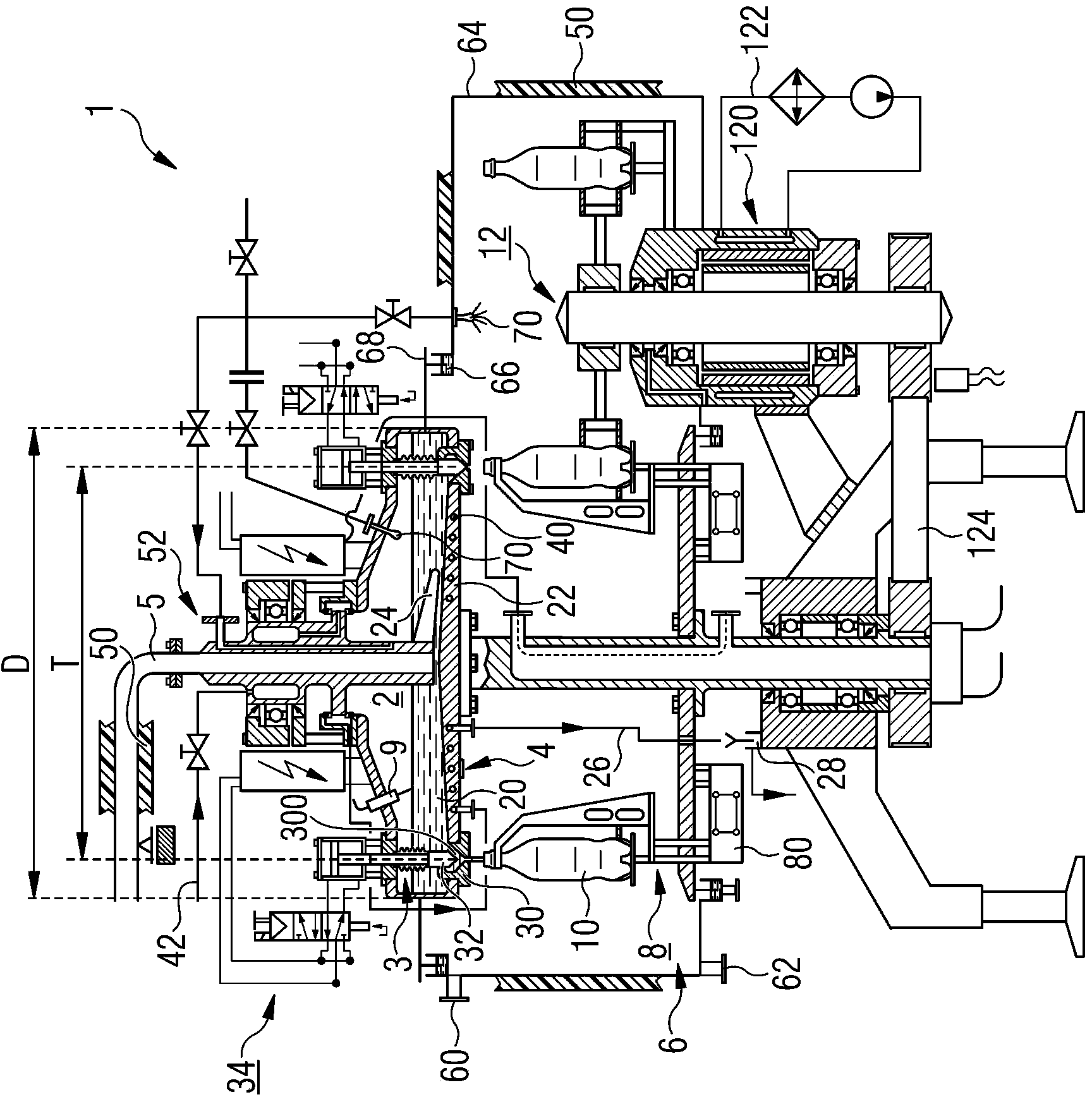

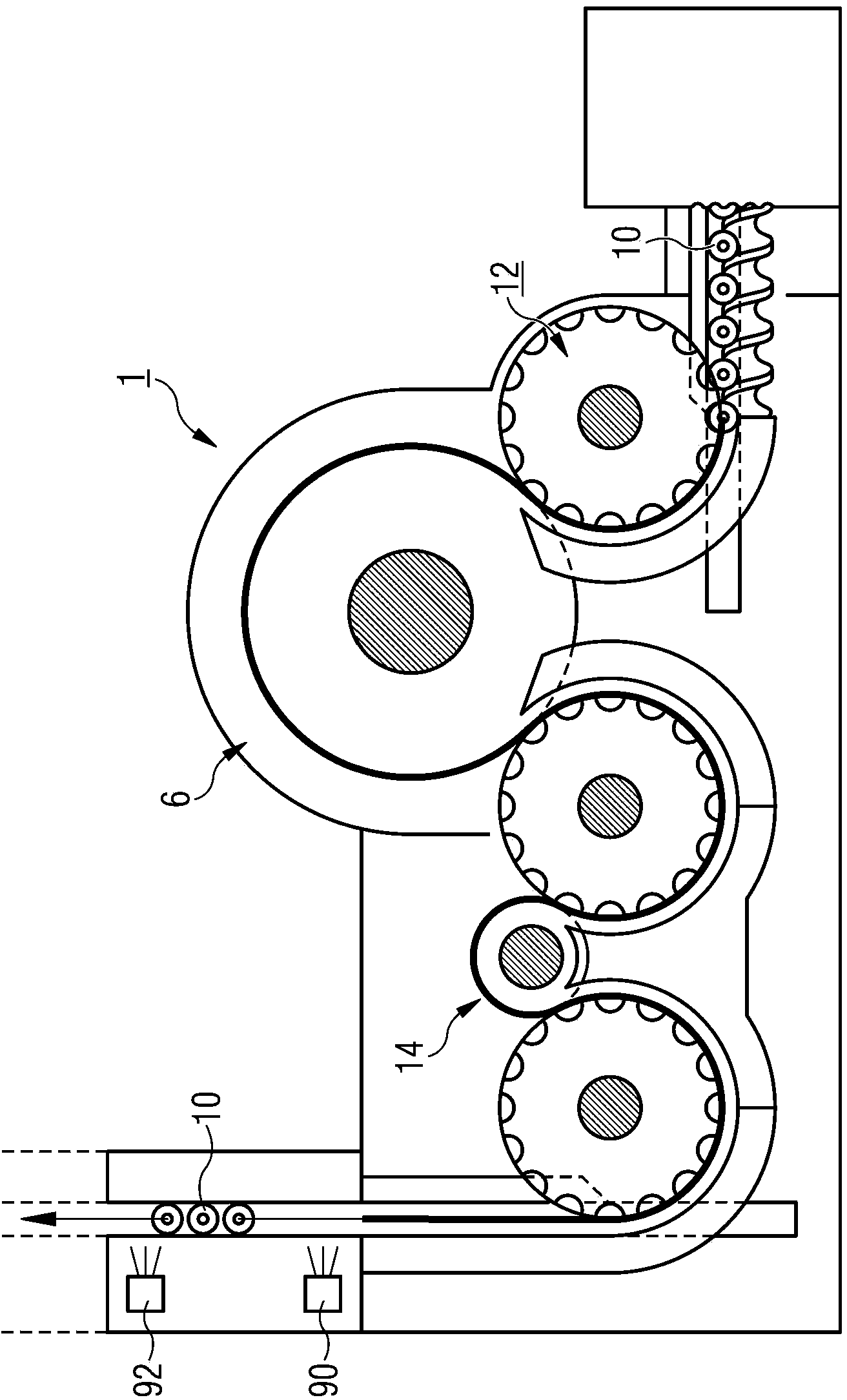

[0033] figure 1 A device 1 for filling bottle-shaped containers is shown schematically, the bottles being fed to the device 1 via a supply star wheel 12 .

[0034] The device 1 comprises a reservoir 2 in the form of a central tank for containing a liquid filling material 20 which is to be poured into the container 10 .

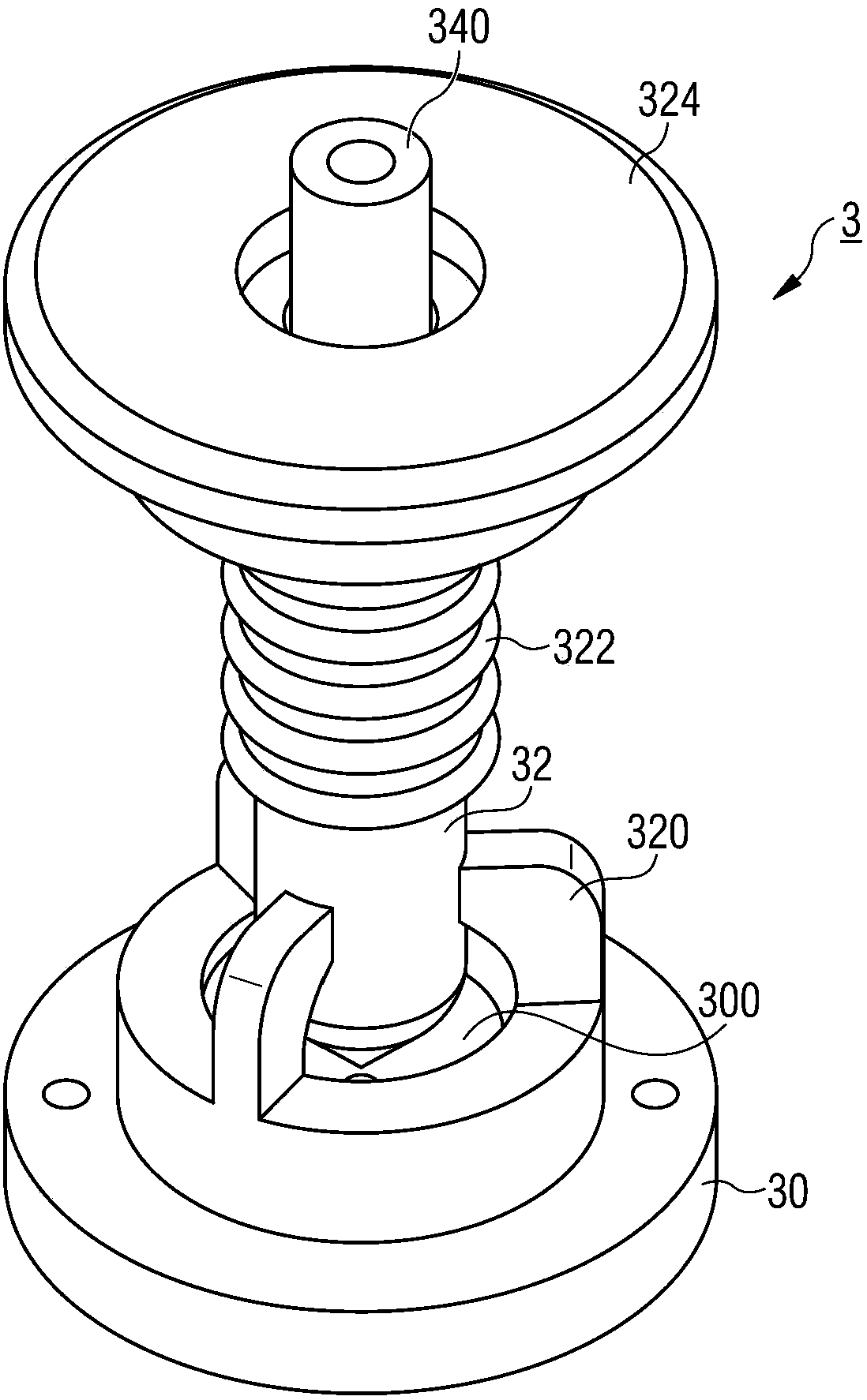

[0035] The liquid filling material 20 can be filled into the container 10 from the storage tank 2 through the filling valve 3 . The filling valve 3 is accordingly in fluid communication with the filling tank 2 in such a way that the liquid filling material 20 contained in the filling tank 2 can flow through the filling valve 3 . the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com