Double-color double-brush double-shake fabric and production method thereof

A technology for fabrics and production steps, applied in the directions of dyeing, fabric surface trimming, heating/cooling fabrics, etc., can solve the problems of unsightly comfort, poor warmth retention, etc., and achieve the effect of comfort, softness and chromaticity

Inactive Publication Date: 2013-12-04

JIANGSU SHENGLI ENTERPRISE

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] With the improvement of people's living standards, people also put forward higher requirements for the clothes they wear. The existing fabrics are made of polyester yarns through cross weaving, which has poor warmth retention and is not beautiful and comfortable to wear.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0018] The heat-retaining agent is HOT2 medicament from Toner, Germany, and the dosage is 3% (O.W.F).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

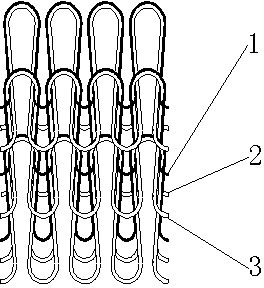

The invention discloses a double-color double-brush double-shake fabric and a production method thereof. The double-color double-brush double-shake fabric is formed by sequentially serially sleeving 150D / 48F plain loops, unicolored 150D / 144FCD cation filar pile loops with stretched sinking arcs and unicolored 150D / 96F pile loops with stretched sinking arcs through weft knitting, wherein the terylenes of the 150D / 144FCD cation filar pile loops with stretched sinking arcs are 70% modified cation terylenes. According to the preparation method, the plain loop layers and the pile loop layers with stretched sinking arcs are sequentially serially sleeved through weft knitting so as to form the fabric, 36 terylene yarns exist in per inch of the double-color double-brush double-shake fabric along the warp direction, and 18 terylene yarns exist in per inch of the double-color double-brush double-shake fabric along the weft direction; after being dyed and baked, the fabric is subjected to aftertreatment, and finally an insulating agent is adhered to the fabric. After being subjected to aftertreatment, the double-color double-brush double-shake fabric is comfortable, soft and stable in chromaticity, meanwhile has an insulating function, and is comfortable and appropriate to wear.

Description

technical field [0001] The invention relates to the field of textiles, in particular to a two-color, double-brush, double-shake fabric and a production method thereof. Background technique [0002] Along with the raising of people's living standard, people also put forward higher requirement to the clothes of wearing, and existing fabric is made of polyester yarn through weaving by cross weaving method, and thermal insulation is poor, and it is not beautiful and comfortable to wear on the body. Contents of the invention [0003] The present invention provides a two-color double-brush double-shake fabric and a production method thereof in view of the above-mentioned deficiencies. [0004] In order to achieve this goal, the method adopted by the present invention is: a two-color double-brush double-shake fabric, the two-color double-brush double-shake fabric is made of 150D / 48F plain stitches and single-color 150D / 144FCD cationic silk belts. The terry loops with elongated s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D04B1/04D04B1/12D06C11/00D06C13/00D06C7/02D06P1/16D06P1/653D06P1/673

Inventor 马晓明许如祥刘桂芬

Owner JIANGSU SHENGLI ENTERPRISE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com