A Binary Nozzle Throat Area Control Mechanism

A binary nozzle and area technology, which is applied to machines/engines, jet propulsion devices, etc., can solve the problems of unsuitable binary nozzles, large required space, and large stroke range, and achieve the realization of binary nozzle throats. The effect of track area control, simple structure, and few moving joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

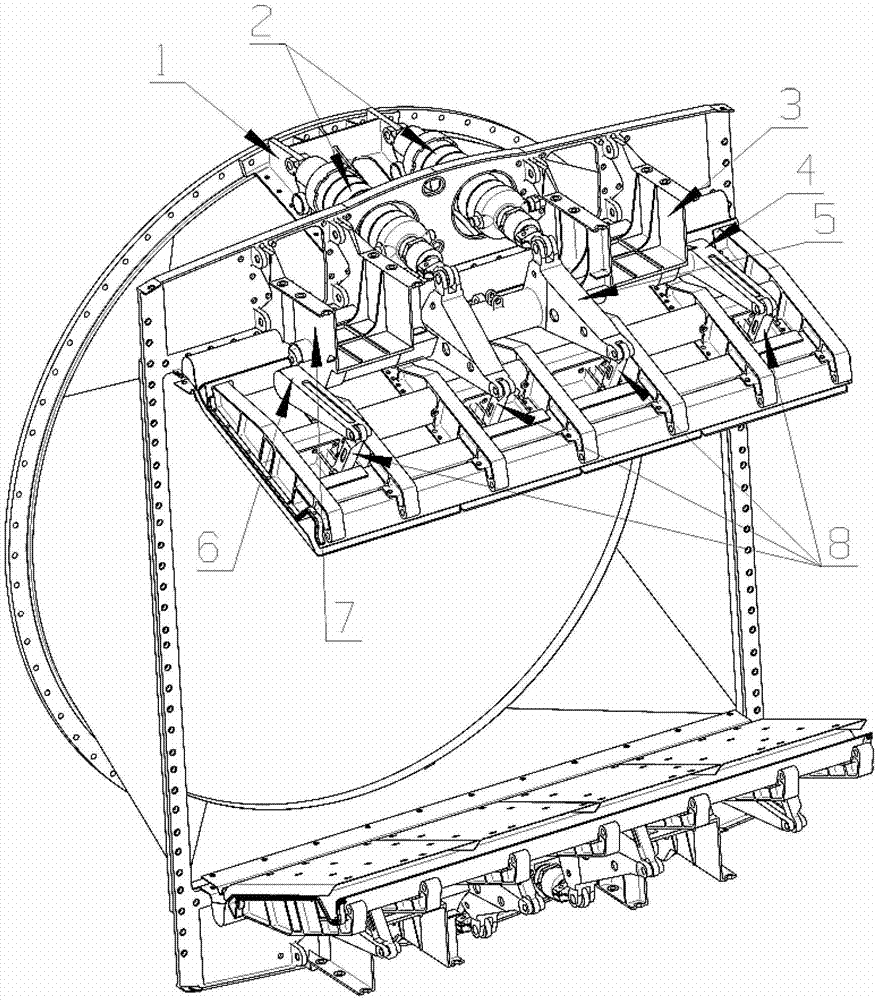

[0022] This embodiment provides a binary nozzle throat area control mechanism, which is characterized in that it includes a drive mechanism and a rocker link mechanism, specifically:

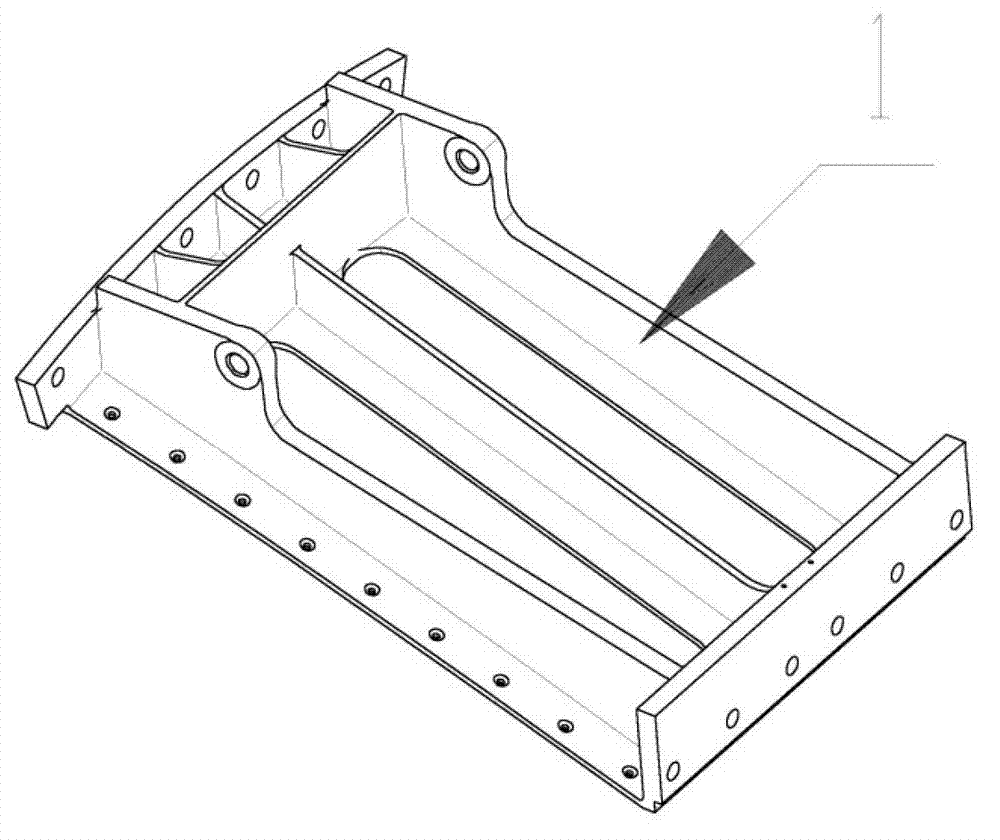

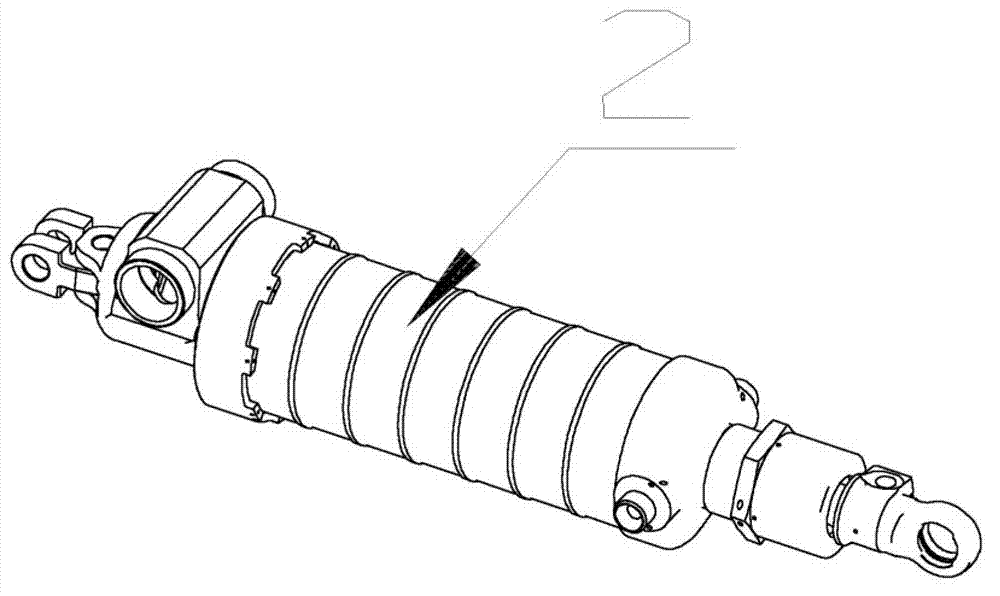

[0023] The driving mechanism includes a mounting base 1 and an actuator 2, wherein the mounting base 1 is fixed on the cylinder body of the binary nozzle; one end of the actuator 2 is hinged to the mounting base 1, and the other end is hinged to the active rocker arm 5;

[0024] The rocker link mechanism includes a first bracket 3, a first follow-up rocker arm 4, an active rocker arm 5, a second follow-up rocker arm 6, a second support 7 and a connecting rod 8, wherein the first support 3, the second support 7 They are respectively fastened to the main body of the nozzle; the first follow-up rocker arm 4 and the second follow-up rocker arm 6 pass through the first support 3 and the second support 7 respectively, and the cylindrical ends of the two are respectively connected to the two ends of the...

Embodiment 2

[0028] This embodiment provides a binary nozzle throat area control mechanism, which is characterized in that it includes a drive mechanism and a rocker link mechanism, specifically:

[0029] The driving mechanism includes a mounting base 1 and an actuator 2, wherein the mounting base 1 is fixed on the cylinder body of the binary nozzle; one end of the actuator 2 is hinged to the mounting base 1, and the other end is hinged to the active rocker arm 5;

[0030] The rocker link mechanism includes a first bracket 3, a first follow-up rocker arm 4, an active rocker arm 5, a second follow-up rocker arm 6, a second support 7 and a connecting rod 8, wherein the first support 3, the second support 7 They are respectively fastened to the main body of the nozzle; the first follow-up rocker arm 4 and the second follow-up rocker arm 6 pass through the first support 3 and the second support 7 respectively, and the cylindrical ends of the two are respectively connected to the two ends of the...

Embodiment 3

[0034] This embodiment provides a binary nozzle throat area control mechanism, which is characterized in that it includes a drive mechanism and a rocker link mechanism, specifically:

[0035] The driving mechanism includes a mounting base 1 and an actuator 2, wherein the mounting base 1 is fixed on the cylinder body of the binary nozzle; one end of the actuator 2 is hinged to the mounting base 1, and the other end is hinged to the active rocker arm 5;

[0036] The rocker link mechanism includes a first bracket 3, a first follow-up rocker arm 4, an active rocker arm 5, a second follow-up rocker arm 6, a second support 7 and a connecting rod 8, wherein the first support 3, the second support 7 They are respectively fastened to the main body of the nozzle; the first follow-up rocker arm 4 and the second follow-up rocker arm 6 pass through the first support 3 and the second support 7 respectively, and the cylindrical ends of the two are respectively connected to the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com